User Manual – ePX 200

OptiPro Systems, LLC.

Page 24 of 60

Last Modified: 7/30/2014

5.9

Work and Tool Holding Chucks

This machine is equipped with manually actuated hydraulic expansion chucks for work and tool holding.

To avoid damaging the chuck, observe the following precautions:

Never actuate the chuck without a properly manufactured shank in the chuck.

Only use steel, aluminum, or similar metals and alloys.

Reducing collets are available. Contact OptiPro for details.

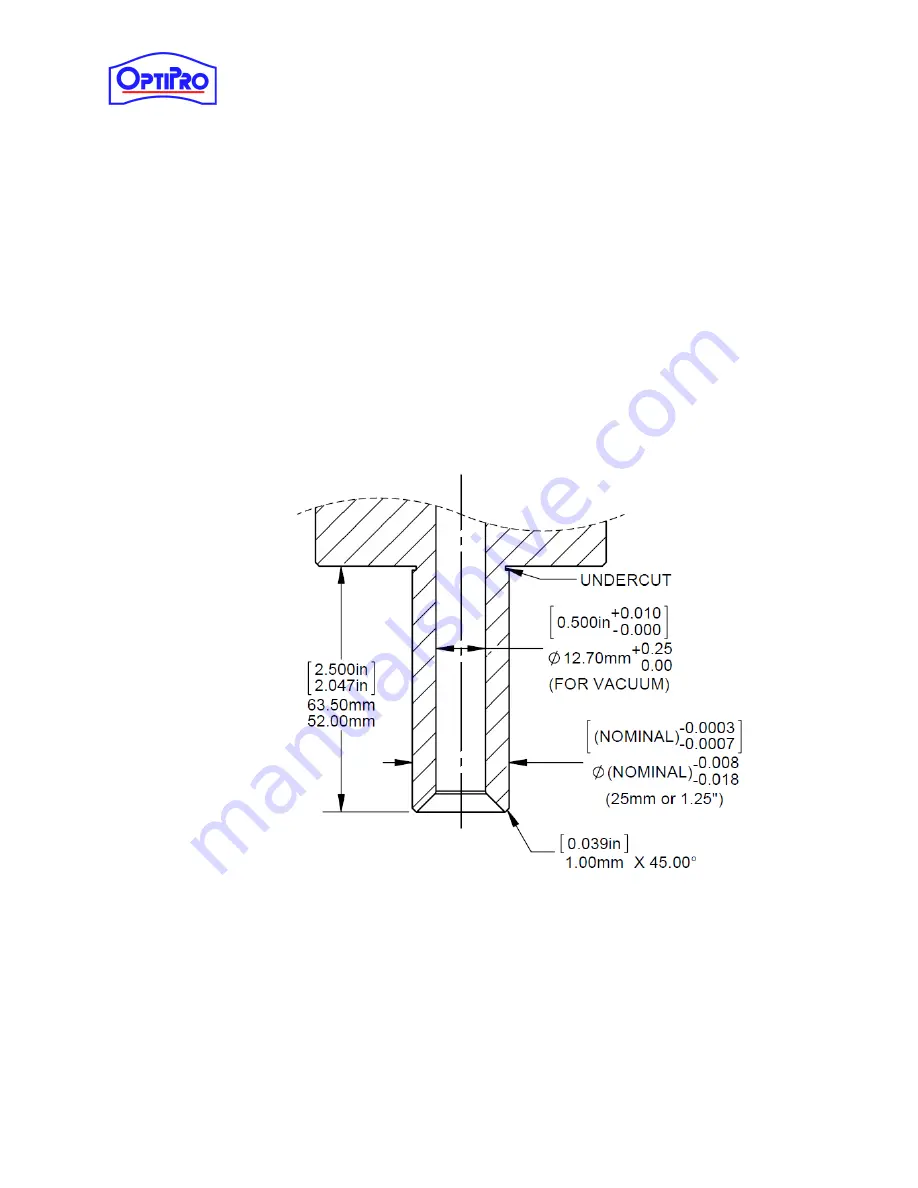

All shanks inserted into the chuck must be within the following tolerance:

o

Shank diameter (either 25mm or 1.25in, depending on customer option) of h7

tolerance (+0µm to -21µm) or better. OptiPro recommends -8µm to -18 µm for best

performance (see print below).

o

Length between 52mm [2in] and 63.50mm [2.5in] must extend into the chuck (see

print below).

Figure 5-20: Recommended shank design. "Nominal" refers to either 25mm or 1.25in.

Always use care when inserting or removing tools to avoid gouging or scratching the chuck.

Always check that the chuck and tools are clean and free from burrs before inserting.

For best performance, turn the chuck actuation screw until it bottoms out. The screw

should always be hand tight. Do not over tighten, and do not use an extension bar or power

tool.