CALIBRATION

Once the transducer has been mounted, and air supply connections finished, the unit’s calibration must be checked before

placing into service.

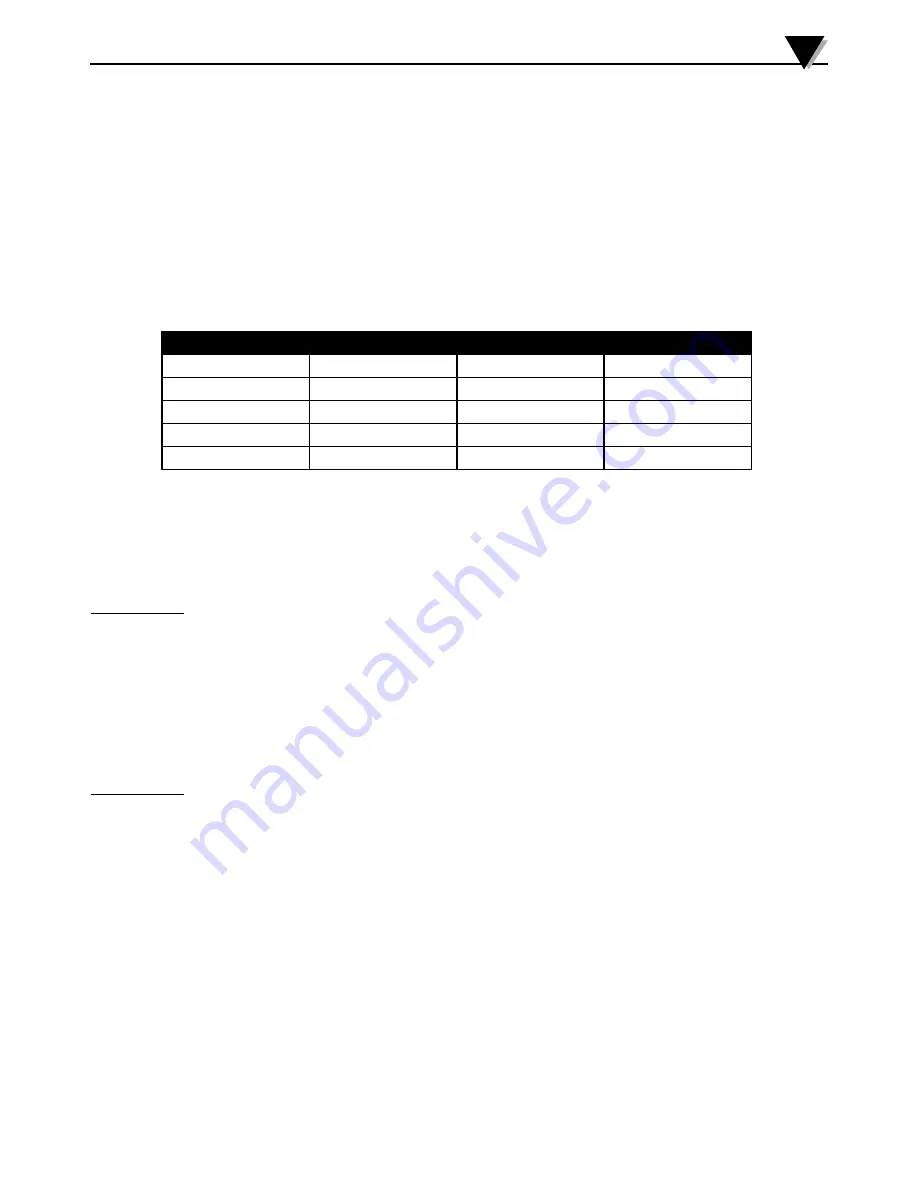

Note: input percentage refers to the following examples:

M4110/

IP211, EP211 SERIES

0519

A

5

If 4 to 20 mA

If 0 to 10 VDC

If 0 to 5 VDC

If 1 to 5 VDC

0% = 4 mA

0% = 0.00 VDC

0% = 0.00 VDC

0% = 1.00 VDC

25% = 8 mA

25% = 2.50 VDC

25% = 1.25 VDC

25% = 2.00 VDC

50% = 12 mA

50% = 5.00 VDC

50% = 2.50 VDC

50% = 3.00 VDC

75% = 16 mA

75% = 7.50 VDC

75% = 3.75 VDC

75% = 4.00 VDC

100% = 20 mA

100% = 10.00 VDC

100% = 5.00 VDC

100% = 5.00 VDC

Forward Acting

1. Apply the 0% input signal to unit and adjust the “Zero” adjusting screw to the low setpoint output. Turn screw counter-

clockwise to increase output. If there is no change in output, keep turning adjustment screw counter-clockwise until

output begins to rise. It is imperative that the output pressure be closely monitored as turning the zero screw excessive-

ly could damage the flexure.

2. Apply the 100% signal to unit and adjust “Span” adjusting screw until output is at the high setpoint.

3.

IMPORTANT:

On I/P (Current) input models, turn the “Span” adjusting screw counter-clockwise to increase output. On

E/P (Voltage) input models, turn the “Span” adjusting screw clockwise to increase the output pressure.

4. Repeat steps 1& 2 until unit is calibrated.

Reverse Acting

1. Apply the 0% input signal to unit and adjust "Zero" adjusting screw until output reaches the high output pressure set-

point. Turn counter-clockwise to increase.

2. Apply the 100% input signal to unit and adjust "Span" adjustment until output pressure is at the low setpoint.

IMPORTANT:

On I/P (Current) input models, turn the “Span” adjusting screw clockwise to increase output. On E/P

(Voltage) input models, turn the “Span” adjusting screw counter-clockwise to increase the output pressure.

3. Repeat steps 1& 2 until unit is calibrated.

Содержание IP211 Series

Страница 8: ...M4110 0519 IP211 EP211 SERIES A 8 Figure 3...