33

07

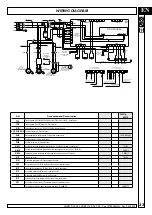

AWG22

AWG18 ORANGE

AWG18 WHITE

YV1 (**)

ST1 (**)

PE

PE

TERMISTORI MOTORE COMPRESSORE

COMPRESSOR MOTOR THERMISTORS

ALLARME REMOTO

(REMOTE ALARM)

L3

L2

L1

LINEA

(ELECTRICAL POWER SUPPLY)

MOTORE ELETTROVENTOLA

RAFFREDDAMENTO

(FU3)

(FU5)

(FU6)

COMANDO ON-OFF REMOTO

(REMOTE ON/OFF)

THERMAL PROTECTION COOLING FAN MOTOR

PROTEZIONE TERMICA

E.VENTOLA RAFFREDDAMENTO

COOLING FAN MOTOR

(FU2)

(FU1)

+

-

L3

L2

L1

2

1

5

4

3

2

1

D1

FU6

control terminal

morsettiera

board

controllo

control terminal

morsettiera

board

controllo

36 (-)

35 (+)

W3

V3

U3

CN9

RS485

CN6

CN7

CN3

CN2

2

1

10

9

8

7

6

5

4

3

2

1

B

A

1 2

1

2

1

2

3

1

CN1

CN4

3

4

5

6

3 4 5 6 7

2 3 4 5 6 7 8 9

12 11 10 9 8 7 6 5 4

FU2

FU3

FU1

FU5

18

22

0 18

32

31

18

0

17

22

22

32 31

ST1

EXTRACTION MOTOR

ELECTRICAL CABINET

(230VA)

VANO ELETTRICO

ESTRAZIONE

MOTORE

KM2

MV2

1

REMOTE ALARM

A DISTANZA

ALL.

CUMULATIVO

19

20

RT

72

71

72

71

20

19

RT

MC

3

72

71

72

71

XI = Lower Terminal Board

XI = Morsettiera inferiore

(230)

(***)

L3

L2

L1

4

09

2

2

2

(***)

W3

U3 V3

BP

T

S

R

19

20

board

control terminal

controllo

morsettiera

24Vac/dc

D2 (OPTIONAL)

RS232 RS485

XS = Morsettiera superiore

XS = Upper Terminal Board

(575)

(0)

XDI(1)

XD24(4)

XAI

XAI

XR03

ELETTROVENTOLA

0

246

245

(0)

(24)

(24)

(0)

PE

KM1

YV1 KM2

KM3

COOLING FAN MOTOR

THERMAL PROTECTION

COOLING FAN MOTOR

COMPRESSOR MOTOR

KM1

32

31

7

6

012

KM2

018

GF

U

FU4

L3

L2

L1

V W

COMPRESSORE

MOTORE

KM1

2

ST3

Q

RAFFREDDAMENTO

09

PROT.TERMICA

MOTORE

RAFFREDDAMENTO

MOTORE

ELETTROVENTOLA

MV3

3

KM3

10

24

5

2

4 4

2

2

2

09

2

2

3

5

2

2

(***)

00

10

SB

KR

11

14

12

L3

L2

L1

11

0

L21

TC1

13

L31

L11

1

(115)

(575)

(0)

TC2

AWG 22 BLACK

AWG1 BLACK

AWG1 BLACK

AWG18 BLACK

AWG18 BLUE

AWG18 RED

AWG18 WHITE

AWG10 BLACK

EN

WIRING DIAGRAM

Ref.

Denominazione/Denomination

100Hp

kW 75

TC1

Trasformatore Pr.0/230/575 300VA Sec.0/24 (20VA) 0/24 (230VA) (Transformer)

TC2

Trasformatore Pr.0/575 Sec.0/115 (Transformer)

SB

Pulsante eme n.2 NC 230V 10A (Emergency button)

FU1.FU2.FU3

Fusibili ceramici 2A (Ceramic fuses)

FU4

Base portafusibile tripolare 600V (Tripolar fuse holder base)

160A (NH1gG)

FU5

Fusibili ceramici 10A (Ceramic fuses)

FU6

Fusibile ceramico 1A (Ceramic fuses)

KM1

Contattore linea alimentazione inverter bob.24 V 50/60 Hz (Inverter line contactor)

75kW

KM2

Contatt. estr.vano elettrico (Electrical cabinet extraction contactor) bob.24 V 50/60 Hz

3kW(*)

KM3

Contattore ventola raffreddamento (Cooling fan contactor) bob.24 V 50/60 Hz

5,5kW(*)

GF

Inverter (Inverter)

75 kW

KR

Dispositivo sequenza fasi (Phase sequence device)

YV1

El. compressore 24 V 50/60 Hz (Solenoide valve compressor pump)

BP

Trasduttore di pressione 0-16 Bar 4-20mA (Pressure transducer)

D1

Controllore elettronico (Electronic controller) 24VAC

D2

Dispositivo SMS (SMS Device) 24 VAC (optional)

RT

Termistori motore compressore (Compressor motor thermistors)

ST1

Sonda termica mandata vite (Temperature probe compressor pump)

Sez. cavo motore (motor cable cross-section area)(mmq) SCHERMATO

4XAWG1

NOBEL DV 45-55_NOBEL 75 E DV CSA - Cod.197EE0696ML - Rev.0 02/2020