25

3 Pre-observation/pre-operation preparation and inspection

●

When inspecting the insertion tube, be sure to hold it at a point behind the angulation section. Otherwise,

the angulation section may be damaged.

●

Also be sure to check the inspection items after using the instrument.

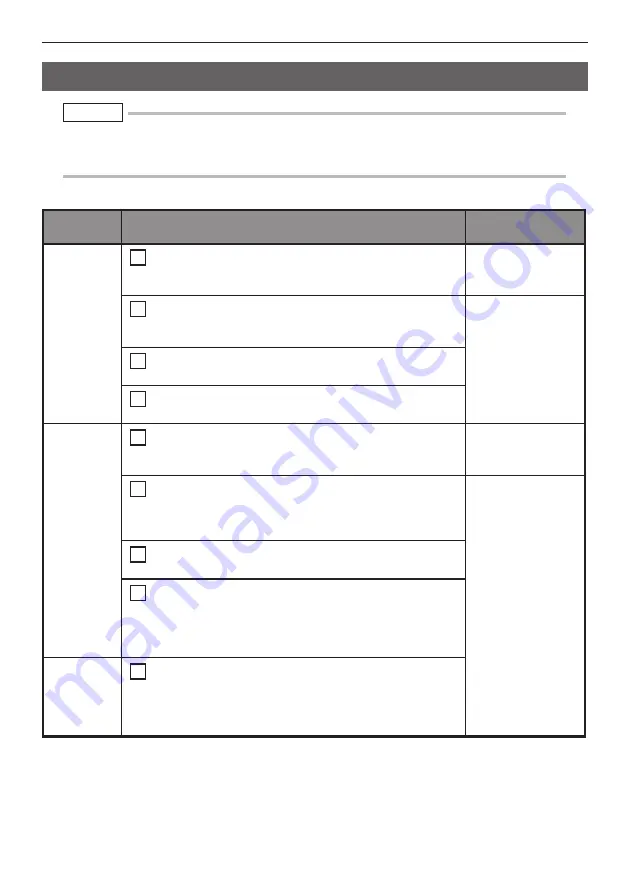

3.3 Pre-operation/post-operation inspections

Inspection

location

Item

If abnormality is

discovered

Overall

Any dirt, sand, or other foreign matter on the control unit,

insertion tube, battery cover, video connector cap, AC

adapter connector cap?

See "7 Storage

and maintenance"

(P. 68).

Any cracks, scratches, or other defects to the control

unit, insertion tube, battery cover, video connector cap,

AC adapter connector cap?

Replacement

required.

Contact Olympus.

Any irregularities such as damage to or deformation of

the exterior material, buttons, joysticks, or levers?

Irregularities such as cuts or kinks in the universal ca-

ble?

Insertion

tube,

angulation

section,

distal end

Any looseness in materials other than the angulation

section?

Replacement

required.

Contact Olympus.

Any dirt or water droplets on the objective lens of the

distal end?

Continued use in this condition creates the risk of

damage to the optical adapter and/or distal end.

See "7 Storage

and maintenance"

(P. 68).

Any build up of dirt on the optical adapter positioning

surface or threads of the distal end?

Any distal end deformation or looseness, or unusual

connecting screw wear?

Never use the instrument while there is any looseness

on the distal end. Doing so creates the risk of loose

parts falling into the inspection object.

O-ring

Is the O-ring missing, broken, etc.?

An O-ring that is misaligned or broken can allow water

or other liquid to get into the joint between the distal

end and optical adapter, creating the risk of malfunc-

tion and damage.

CAUTION