Construction Manual

www.oldschoolmodels.com

Page 11

Step 53 - Wing Assembly (join wing halves)

Test fit the wing halves together one last time and sand as necessary

for a good fit.

After test fitting, join the wing halves permanently with 30 minute

epoxy. Remove the dihedral brace and apply the epoxy into the

pockets in each wing half and also coat the faces of each root rib.

Slide all the dihedral brace into one of the wing halves, then slide

remaining wing half in place. Using a couple of clamps (or tape),

hold wing halves firmly together. Wipe off any excess epoxy and

remove the clamps only after the epoxy has fully cured.

Remember, any twist in the alignment of the panels cannot be

fixed after the epoxy cures and will lead to a poor flying model.

This completes assembly of the Kaos 60 wings.

Now it’s time to start construction of the tail surfaces.

Prepare your work area

Now tape the elevator/stab plan and a fresh piece of waxed paper

on your building board.

Step 54 - Horizontal Stab Assembly (trailing edge)

Locate a 1/4” x 1/2” x 36" balsa

strip, measure and cut a piece

to form the trailing edge of the

horizontal stab as shown on the

plans. Pin this piece in position,

using a straight edge to make sure

it's straight along it's entire length.

Step 55 - Horizontal Stab Assembly (S1)

Locate both S1s from BP1.These are

glued to the trailing edge as noted

on the plans.

Glue one S1 in place first, then the

other S1 on top, making sure they

are perfectly aligned.

Step 56 - Horizontal Stab Assembly (S2)

Locate four S2s from BP1 and BP2.

These are glued to the outer edges

of the trailing edge, two on each

side.

Glue one S2 in place first, then the

other S2 on top , making sure they

are perfectly aligned.

Then do the same for the opposite

end.

Step 57 - Horizontal Stab Assembly (leading edge)

Next is to cut and install the

leading edge pieces. Check

your scrap pile to see if you

have the proper length first,

but if not, use an uncut length

of 1/4” x 1/2” x 36" balsa strip.

Glue these in position.

Step 58 - Horizontal Stab Assembly (internal bracing)

Locate a length of 1/4" square

balsa stick. Use this to cut the 8

internal brace pieces, 4 on each

side. Take some extra time to get

the angles correct to help the

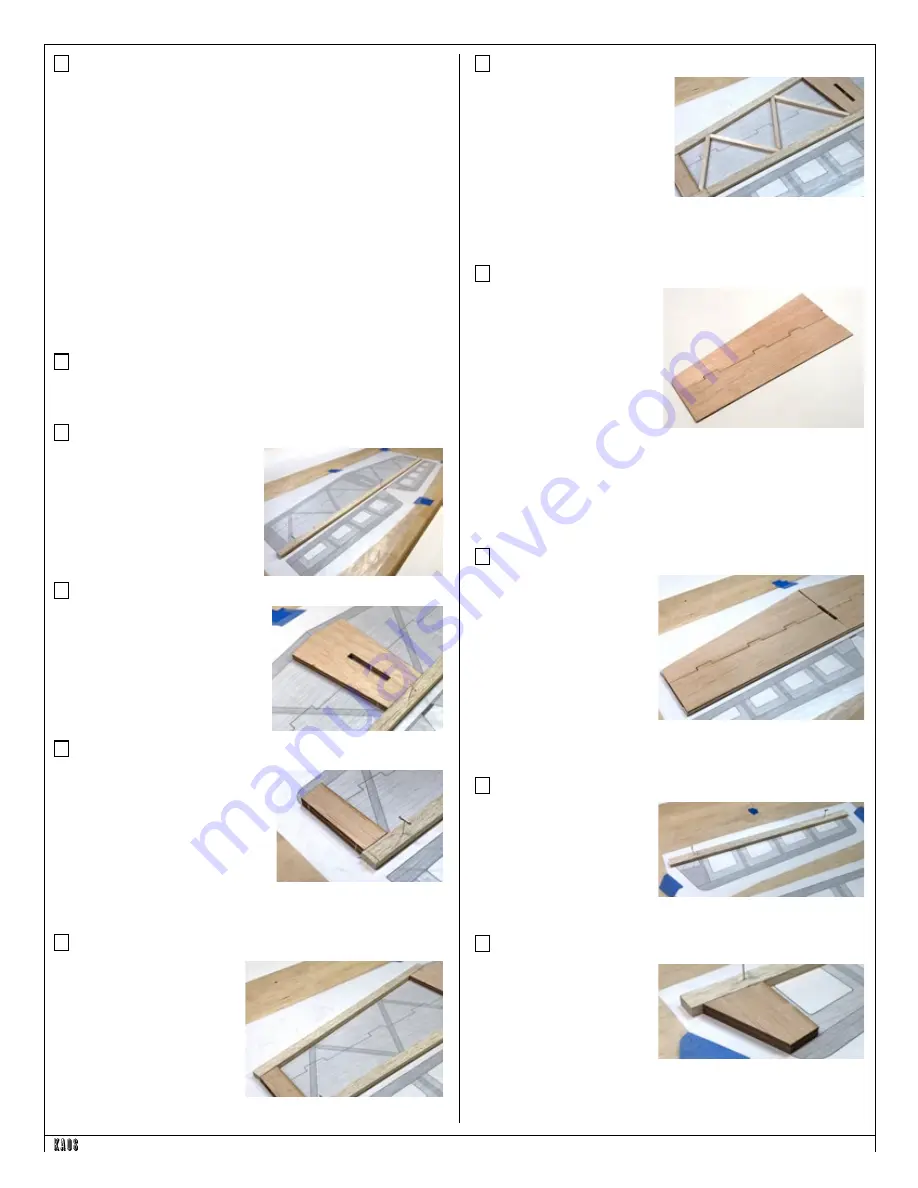

glue do it's job.

Carefully run a sanding block

over this framing assembly to make sure it's perfectly flat.

Step 59 - Horizontal Stab Assembly (outer sheeting)

Locate four ES1 and four ES2

from BP8. An ES1 and ES2 are

glued together to form a half

sheet as shown here.

These pieces will properly only

fit together one way.

When edge gluing the

sheeting pieces together, first

make sure the edges fit first.

When the adhesive is applied, place the sheeting on the waxed

paper, so that it’s flat (as shown in the photo). Hold it flat with a

weight until it's cured to make sure it stays flat. When cured, you’ll

now have a single piece of sheeting.

Do this 3 more times to create 4 sheeting halves.

Step 60 - Horizontal Stab Assembly (outer sheeting)

Take two of the sheeting

halves from the previous

step and glue them to the

top of the elevator framing.

When cured, remove the

assembly, flip it over and

give the open framework a

quick sand just as you did

before.

Then apply the remaining two sheeting halves to complete the

elevator.

Step 61 - Elevator Assembly (outer sheeting)

Next is to cut and install the

leading edge pieces of the

elevator. Check your scrap

pile to see if you have the

proper lengths first, but if

not, use an uncut length of

1/4” x 1/2” x 36" balsa strip. Pin these in position.

Step 62 - Elevator Assembly (S3)

Locate four S3s from BP1

and BP2. These are glued

to the inner edges of the

leading edge, two on each

side.

Glue one S3 in place first,

then the other S3 on top ,

making sure they are perfectly aligned.

Then do the same for the other elevator half.