014-4 LT00102W-E.DOC

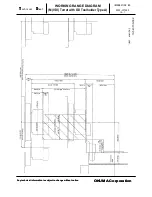

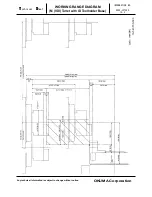

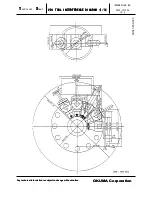

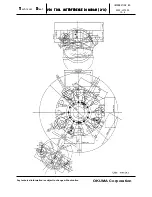

About work length range:

The workpiece length can be represented by the difference obtained by subtracting the minimum workpiece

length that can be gripped by the chuck in the work conveyor position (Lmin) from the maximum workpiece

length that can be carried by the spindle without interference (Lmax). (See the figures below.)

Work length range = Lmax

−

Lmin

If, for example, a standard chuck (N-08A601A) is equipped with soft jaws A,

Lmin = 100 mm, and

Lmax = 200 mm.

Therefore, the work length range will be 200

−

200 = 100 (fixed).

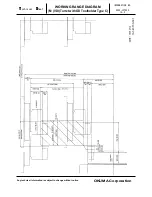

If the workpiece length is smaller than Lmin or larger than Lmax, take the following measures.

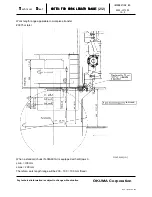

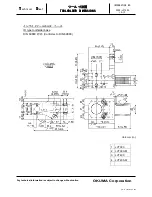

1) If the workpiece length < Lmin, and the difference in work length among the several workpieces handled <

Work length range (100 mm).

- Place workpiece bases on the work conveyor to raise the work feeding position.

- Use the soft jaws B (with 80-mm jaw length [42 mm for soft jaw A]).

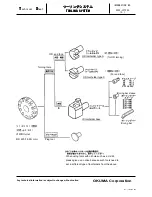

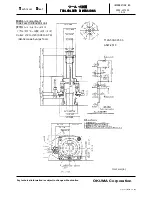

2) If the work length > Lmax, and the difference in work length among several workpieces handled < Work

length range (100 mm).

- Lower the work conveyor position to lower the work feeding position.

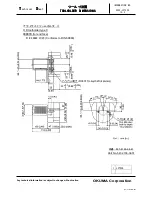

3) If the work feeding height cannot be adjusted with the above measures 1) or 2); i.e., the difference in work

length among several workpieces handled > Work length range (100 mm),

- Use a special work conveyor such as a height adjustable type or the one with work conveyor lifter.

T

TT

T

echnical

S

SS

S

heet

NOTES FOR WORK LENGTH RANGE

NOTES FOR WORK LENGTH RANGE

NOTES FOR WORK LENGTH RANGE

NOTES FOR WORK LENGTH RANGE

(1/2)

INFORMATION NO.

2059-LVT300

14-4

Any technical information is subject to change without notice.

OKUMA Corporation

Unit: mm (in.)