OFNA RACING , 7 VANDERBILT, IRVINE, CA. 92618 • TEL:(949)586-2910

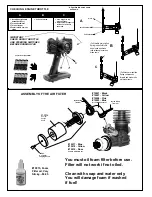

FORCE PULL START ENGINES

Thank you for purchasing an OFNA engine. We appreciate your choice and know you will enjoy running it. Please

note that the Force information in engine box is subject to change with out notice.

Carburetor Low end and barrel stop screws are pre-set by factory.... Do not change until break-in is done.

NEW ENGINE BREAK-IN

Your OFNA engine is extremely tight when the piston is at the top of the stroke and turning the crankshaft by hand.

This is normal for a new ABC type engine. The piston and sleeve are matched for fit and the top of the sleeve is

tapered for a tight fit. As you run your engine, this tightness should diminish. There is no cause for alarm, because

as the engine warms up, the brass sleeve will expand faster than the aluminum piston and the engine will turn freer.

As with any new engine, there are many high spots and tight fits in the matching process. High spots create hot

spots that must be broke-in. Therefore, the break-in process is very important to provide good service by the OFNA

engine. So, you must run the engine rich (COOL) for the first three tanks of fuel. We recommend using one gallon

of 20% BLUE THUNDER 0R BYRON’S 2000 as break-in fuel. Other break-in type fuels or added oil is NOT

needed. DO NOT OVER REV THE ENGINE WHEN FIRST STARTING, this could break the piston and over heat

sleeve. Let engine run at low RPM for one tank to break-in connecting rod bearing before starting full break-in.

Break-in the engine in the car, by running the engine at a rich setting. Run the car from a slow to fast speed with

short bursts of speed. You need to buildup a little heat in the engine, but not too hot. In a rich setting, the engine

will run cold. In the leaner setting the engine run hot, this is not good yet. Do not heat up the engine too much at

this time. After about one (1) tank, turn the Master Needle Valve, clock wise, 1/8 of a turn leaner or clockwise.

Keeping the fuel tank full, continue the process until you slowly turn the Master Needle Valve, 1/8 of turn each time,

too a leaner point and in which the engine runs at high RPM and power, but still keep max temp. of 250 deg. F. At

this point you must stop, too lean of a setting will heat up engine and damage the piston. A normal operating

temperature is around 220 to 270 Deg. Temperatures of 300 Deg. and above will damage engine and shorten life.

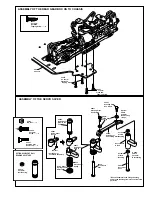

NEEDLE SETTINGS

Master Needle Valve - main control for fuel mixture. Set at 3 to 31/2 turns from closed. Adjust this needle for

maximum RPM and power without being too lean or too hot. Make sure you start at bottom of needle seat!!

Side Carburetor Needle (Low Speed) - This needle is in the center side of the carburetor and provide throttle

response. It is not the idle adjustment. Set FLUSH with the brass sleeve. Turning in is Lean and Out is Rich. Do

not adjust this needle until the Master Needle is set for power and top speed. This will only effect throttle response.

FOR THREE NEEDLE CARBURETORS, DO NOT ADJUST MID RANGE NEEDLE, PRESET BY FACTORY

Barrel Stop Screws - Used for adjusting Idle. Set for 1/16th inch gap to start new engines. You can open more for

faster idle.

USE LONG GLOW PLUG WITHOUT IDLE BAR,

OFNA/PICCO #51007 & 51008 IS RECOMMENDED