18

GLOWPLUG

The role of the glowplug

Glowplug life

Particularly in the case of very high performance

engines, glowplugs must be regarded as expendable

items. However, plug life can be extended and engine

performance maintained by careful use, i.e.:

Install a plug suitable for the engine.

Use fuel containing a moderate percentage of

nitromethane unless more is essential for racing events.

Do not run the engine too lean and do not leave the

battery connected while adjusting the needle.

With a glowplug engine, ignition is initiated by the

application of a 1.5-volt power source. When the

battery is disconnected, the heat retained within the

combustion chamber remains sufficient to keep the

plug filament glowing, thereby continuing to keep the

engine running. Ignition timing is 'automatic' : under

reduced load, allowing higher rpm, the plug becomes

hotter and, appropriately, fires the fuel/air charge

earlier; conversely, at reduced rpm, the plug become

cooler and ignition is retarded.

Apart from when actually burned out, a plug may

need to be replaced because it no longer delivers its

best performance, such as when:

When to replace the glowplug

Filament surface has roughened and turned white.

Filament coil has become distorted.

Foreign matter has adhered to filament or plug

body has corroded.

Engine tends to cut out when idling.

Starting qualities deteriorate.

Since the glowplug and fuel combination

used may have a marked effect on

performance and reliability, it would be

worthwhile to experiment with different

plug types. Recommended O.S. plugs are

No.8, No.7 and No.10 (Former A5) .

Carefully install plug finger-tight, before

final tightening with the correct size plug

wrench.

19

With a fixed-wing model, power failure is rarely a

serious threat to the safety of the aircraft since it can

usually glide down to a safe landing. In a helicopter,

on the other hand, it is vitally imporant that the engine

keeps running and that there is a quick and reliable

response to the throttle in order to ensure safe ascent

and descent of the model.

The High-Speed (Main) Needle Valve

When set to produce maximum power at full

throttle, this establishes the basic fuel/air mixture

strength. This is then maintained by the carburetor's

automatic mixture control system to cover the

engine's requirements at reduced throttle settings.

The Idle Mixture Control Screw

This provides the means of manually adjusting the

mixture control valve. By setting the Mixture Control

Screw for the best idling performance, the mixture

control valve automatically ensures that fuel is

accurately metered to maintain the correct mixture

strength as the throttle is opened.

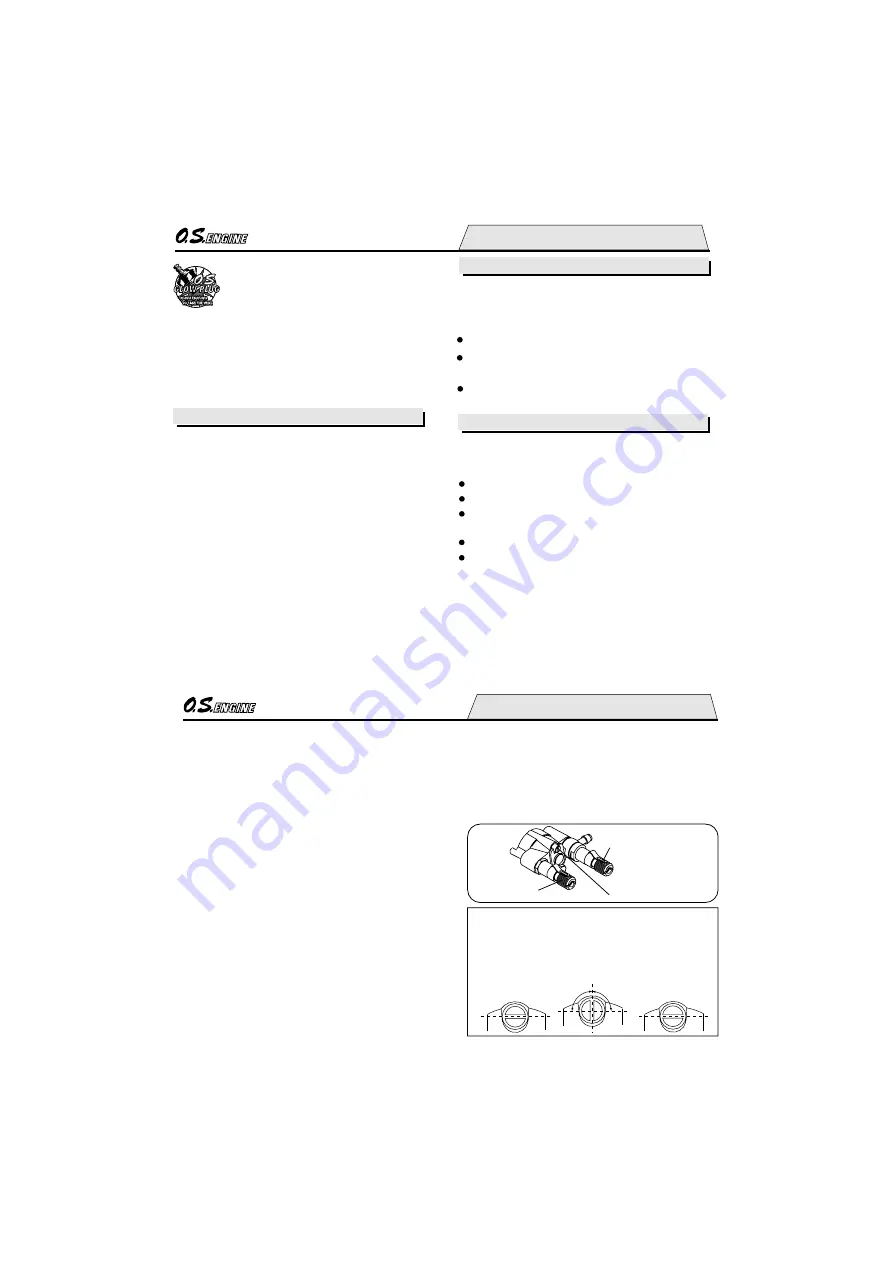

Three adjustable mixture controls are incorporated in the

Type 40L. They are as follows.

A

B

The Medium Speed Needle Valve

This is an extra control that can be brought into

play, if necessary, after adjusting A and B above. It

provides the means of fine-tuning mixture strength

over that all-important part of a helicopter's throttle

range where the model is flying in, or near, the

hovering mode.

C

Idle MIxture Control Screw

High Speed Needle Valve

(Main Needle)

Medium Speed

Needle Valve

As the idle mixture control screw is installed with

LOCTITE, it may initialy feel stiff, and it is suggested

to use a slightly oversized screwdriver. The screw can

be turned only 90 degrees either way. Do not force to

turn further, or it may break or cause trouble.

NOTE

90 degrees

90 degrees

CARBURETOR CONTROLS