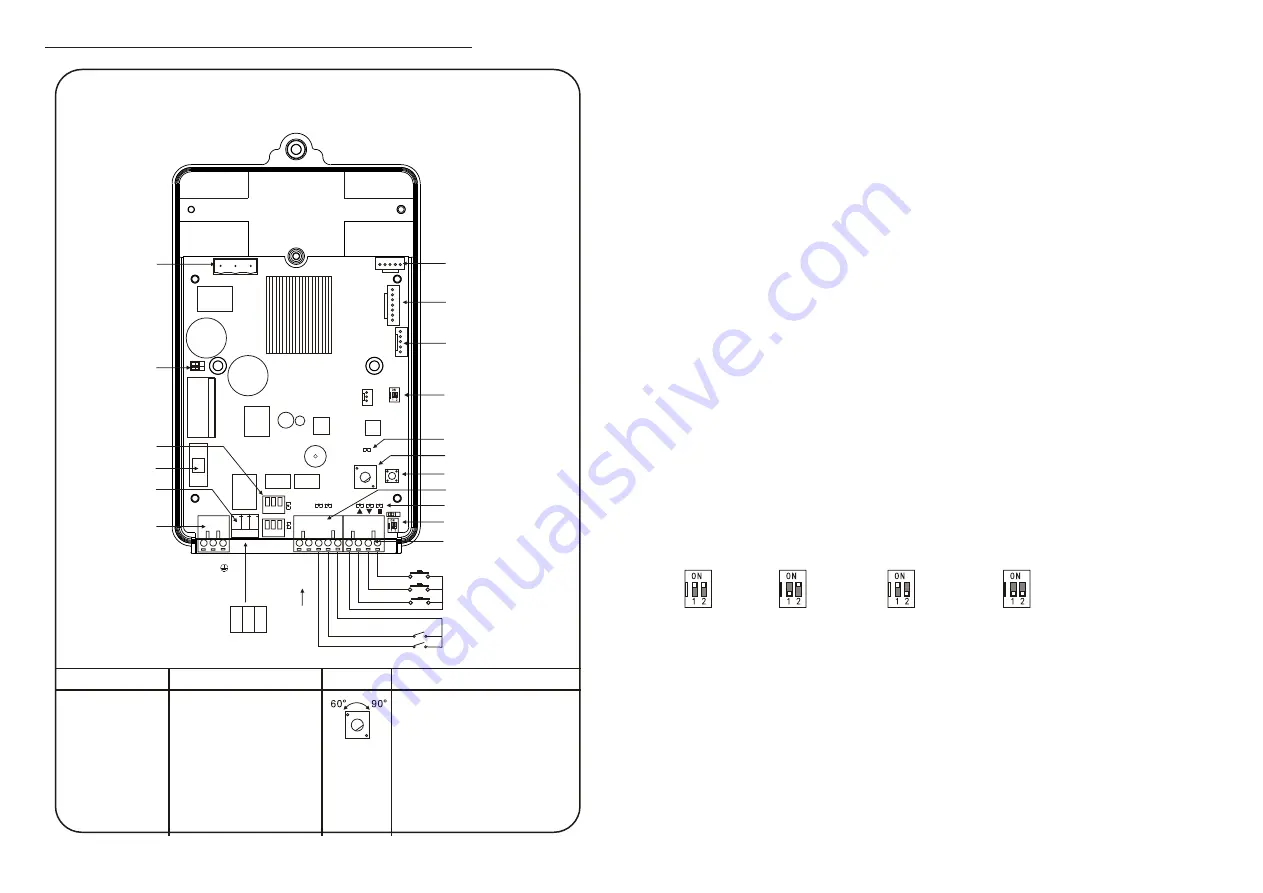

7. Controller Explanations and Instructions

Wire Diagram

Motor Interface

220V/110V

Switch Jumper

Cap 1

UP/DOWN Limit

Signal Output

Interface and

Indicators

Fuse

R & G L i g h t

Interface

P o w e r I n p u t

Interface

MotorEncoder

Interface

MotorSensorIn

terface

RemoteControll

erInterface

DIP Switch 2

Function Indicator

Boom Up Angle Adjustment

Knob

SET

+-

DC

12

V

<

0

.

2

A

L

N

Signal Input Indicator

Photocell and Loop Detector

Interface

J1 DIP Switch 1 and Jumper 1

Wire Control Interface

STOP

DOWN

UP

COM

COM Interface

Loop Detector Signal Input

Photocell Signal Input

P

h

o

to

c

e

ll P

o

w

e

r

R

e

d L

ig

h

t

G

re

e

n L

ig

h

t

C

O

M

DIP Switch Setting

DIP Switch 1: Speed setting

ON/ON: 3S; OFF/ON: 4S;

ON/OFF: 5S; OFF/OFF: High

intensity of auto-reversing

DIP Switch 2:

DIP 1: Signal type

O F F : N o r m a l O p e n , O N :

Normal Close

DIP 2: Learning mode after

power-on

OFF: Boom up and down; ON:

Boom up only

Jumper 1: Auto-aging test

Left: close; Right: open.

Delay Auto-closing Setting

Pressing and holding SET button then power on,

if the Function Indicator constant lighting means

delay auto-closing function is of f if twinkling,

the twinkling times is the seconds of the delay

auto-closing.

Opening method: Press UP button (of the remote

controller) to open this function, after open, the

delay auto-closing time is 3 seconds, each

pressing of the UP button increases by 1 second,

the max is 60 seconds.

Closing method: Press S TO P button, the

Function Indicator constant lighting means close.

Read seconds: Press DOWN button, the Function

Indicator twinkling times is the seconds of the

delay auto-closing.

Release the SET button to save and start

working.

Boom Up Angle

Setting

Counterclockwise

to the end is 60

°

Clockwise to the

end is 90

°

Middle is end is

60

°

~85

°

Horizontal and vertical fine adjustment

Horizontal adjustment: In UP limit status, pressing

and holding SET button, then press UP button (of the

remote controller) (if angle over 90

°

) or DOWN

button (if angle less than 90

°

) to adjust the value

(0~25). Release the SET button, the adjustment is

done when the boom open to the UP limit status next

time.

Vertical adjustment: In DOWN limit status, pressing

and holding SET button, then press OPEN button (of

the remote controller) (if angle less than 0

°

) or

DOWN button (if angle over 0

°

) to adjust the value

(0~40). Release the SET button, the adjustment is

done when the boom close to the DOWN limit status

next time.

Note: During adjusting, when press STOP button, the

twinkling times of the Function Indicator means the

current adjusted value.

7.1. Controller interface explanations

All the electrical connections are done before delivery. The necessity is to

connect the power and grounding connection. Explanations and instructions

for the main function interfaces and indicator light is as following:

7.1.1. 220V/110V switch jumper cap:

This barrier motor and controller support AC220V/110V power input, the

jumper cap is plugged in before delivery, if need to change the input voltage,

please plug the jumper cap into correct position before power on (plug on the

left is 220V, plug on the right is 110V).

7.1.2. R&G light interface:

This function is no power, same as switch, MCOM ” need to connect with

corresponding power of the R&G light. When boom falling down to

horizontal position, red light will keep lighting; when boom lifting up to

vertical position, green light will keep lighting. During the boom falling down

or lifting up, the red light will keep lighting. (Please refer to Appendix II for

wire diagram)

7.1.3. Wire control signal input interface:

This interface is dry contact input signal, UP/ DOWN / STOP connect with

MCOM ”, the control board will respond accordingly. User can use this

interface to connect with parking system, and it can also connect button

switch to control the barrier. (Please refer to Appendix III for drive

requirement for main control board wire control)

7.1.4. Photocell and loop detector interface:

This interface is dry contact input signal, only for responding opening when

shorts circuit MPhotocell” and“ COMH during closing, responding closing

when shorts circuit “ LoopHand MCOMH if opening to up limit position,

responding opening when shorts circuit “ LoopHand MCOMH during

3S

4S

5S

Hig h intensity of

auto-reversing

7.1.7. Jumper 1:

This Jumper is for closing (insert left) or opening (insert right) auto-

aging test function; Opening this function can realize barrier gate auto-

open, close, and open during closing process for auto-aging test.

7.1.8. DIP Switch 2:

DIP 1 for setting signal input type, means the wire signal input type of

“STOPH, MLOOP DETECTOR” and “PHOTOCELL”. DIP set to be

OFF, means the barrier responses action when short circuited signal interface

and COM interface; DIP set to be ON, means the barrier responses action

when disconnected signal interface and COM interface.

DIP 2 for learning mode after power-on: set to be OFF, means the

barrier will open and close slowly one time after power-on; set to be

6

.

.

7

.

.