GENERAL SAFETY CONSIDERATIONS

DANGER: COMPRESSED AIR COULD CAUSE DEATH, BLINDNESS

OR INJURY.

1. Do not operate a Vortex A/C at compressed air pressures

above 150 psig (10.3 bar).

2. Do not operate a Vortex A/C at line temperatures above 110

o

F

(43

o

C).

3. Avoid direct contact with compressed air.

4. Do not direct compressed air at any person.

5. When using compressed air, wear safety glasses with side

shields.

Avertissements pour Vortex A/C NEMA 4/4X Modèles

VA091604X, VA151604X et VA251604X:

ATTENTION! Pour maintenir la norme UL type 4 / 4X: Lorsque

monté sur la partie supérieure d’un boitier, cet appareil doit être

installé debout et dans une orientation verticale. Lorsqu’il est

monté sur le côté d’un boitier, cet appareil doit être installé de

sorte que l’entrée d’air comprimé est orientée vers le haut, OU,

de sorte que le carénage en acier inoxydable est orienté vers le

bas. Voir les instructions d’installation.

ATTENTION! Les surfaces extérieures de cet appareil peuvent

être chaudes. Eviter le contact.

INTRODUCTION

A Vortex A/C enclosure cooler is designed to use filtered

compressed air to cool industrial control cabinets without the use of

any refrigerants. Hot air in the cabinet is vented to the surroundings

through a built-in vent in the Vortex A/C. Noise generated by the

Vortex A/C is comparable to normal speech levels. The Vortex A/C

has a built-in mechanical thermostat that requires no electricity.

To operate, simply install on your enclosure and connect the

compressed air source.

COMPRESSED AIR SUPPLY

The compressed air supply must be filtered (5 micron maximum)

to remove water and dirt. A 5 micron filter is supplied for this

purpose (Hoffman model VAAF15 or VAAF25). If oil is present in

the compressed air supply, remove the oil using an optional 0.01

micron coalescing filter (Hoffman model VC-OF17 or VC-OF25).

Filter recommendations are given in Table 1.

If an oil removal filter is necessary, install it downstream of

the 5 micron filter. Change the filter elements as needed (see

Maintenance).

The appropriate size of compressed air supply line should be selected

to ensure optimal performance of the Hoffman product. Please refer

to Table 2 to determine what supply line size is recommended for

your application. Contact nVent Hoffman for assistance, phone

#763.422.2211.

INTERNAL CABINET PRESSURE

The Vortex A/C, when operating at 100 psig (6.9 bar), will maintain

the internal enclosure pressure at approximately 35” (889 mm)

of water column. When the Vortex A/C is not cooling (when the

thermostat senses acceptable temperatures), the Vortex A/C is not

pressuring the enclosure. If you desire a constant positive internal

enclosure pressure, even when the Vortex A/C is not cooling, this

may be accomplished by removing a set screw that is adjacent to the

mechanical thermostat on the bottom of the unit. By removing this

set screw with a 3/32” (2 mm) hex key), a small amount of air (3 cfm

or 85 lpm) will pressurize the sealed enclosure to approximately 1.5”

(38 mm) water column. This “pressurization air” will run continuously,

regardless of the thermostat operation, until the set screw is re-

installed.

MAINTENANCE

The only maintenance involved with the Vortex A/C is normal element

changes to the compressed air filter. The filter element should be

changed when there is a noticeable decrease in performance or

when pressure drop across the filter exceeds 5 psig (0.3 bar). The

Vortex A/C has only one moving part (the mechanical thermostat/

valve) which is not serviceable in the field. Do not disturb the setting

of the thermostat. Evidence of tampering with the thermostat may

void the warranty.

If it is suspected that the compressed air filter has not been

maintained after an extended period of operation, there may be dirt

in the Vortex A/C. If the Vortex A/C is not cooling sufficiently, there

may be debris in the “generator” of the unit. To check, pull the 1/2”

(13 mm) inside diameter vinyl tubing off the cold air outlet of the

Vortex A/C and unscrew (with a 1” (25 mm) open end wrench)

the cold air outlet. Remove the O-ring. Remove the white nylon

washer(s). Then remove the red (model VA091604X) or the blue

(model VA151604X) or the brown (model VA251604X) generator.

Inspect the six slots in the generator for dirt and clean if necessary.

Clean the cavity in the Vortex A/C that the generator was located in

if necessary. Reassemble in reverse order. Tighten the cold air outlet

to 100 inch-pounds (11 newton meters) torque. Be sure to supply

clean (filtered to 5 micron) and oil free compressed air to the Vortex

A/C.

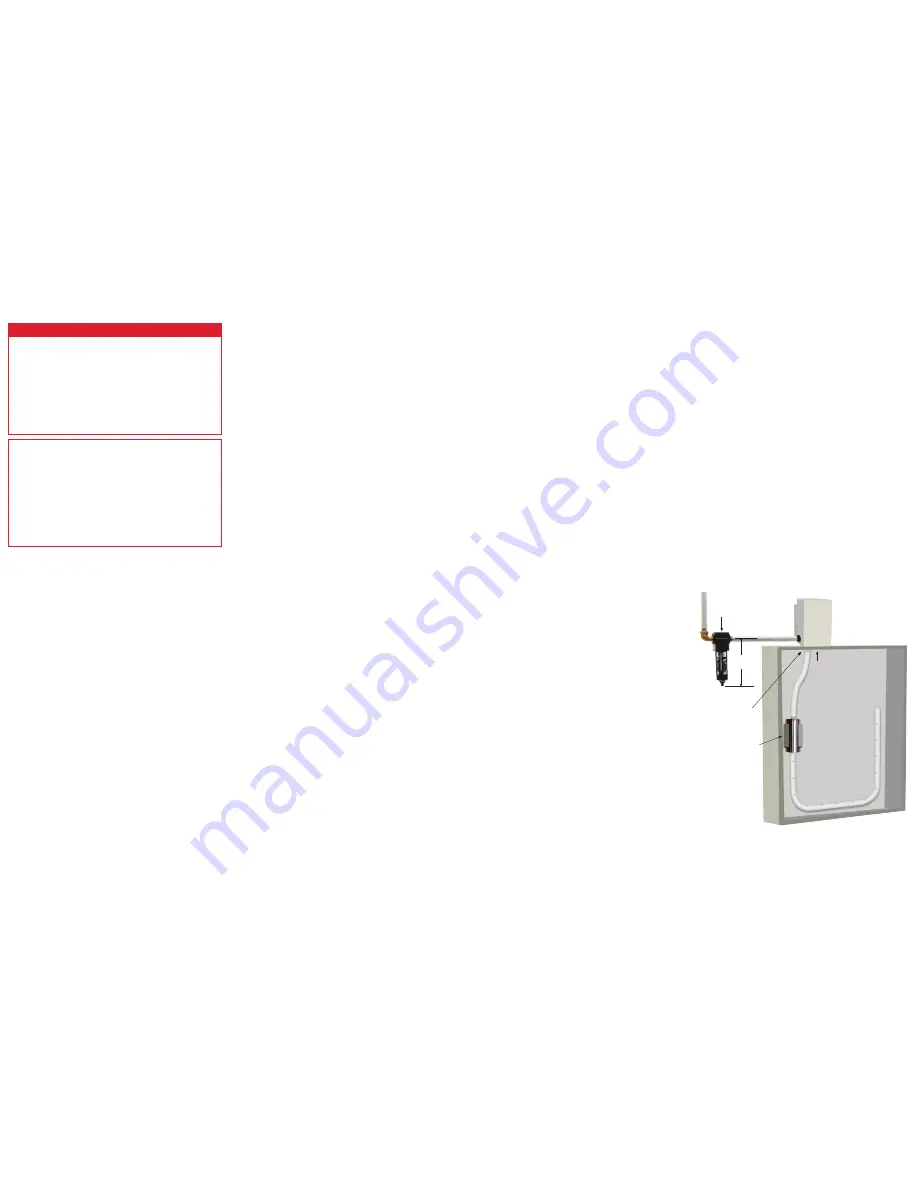

INSTALLATION

To maintain the UL Type 4 and 4X rating, the Vortex A/C MUST be

installed in one of the following configurations on a UL Type 4 or 4X

enclosure:

a. Top mounted in an upright and vertical orientation, on a

flat horizontal surface (as shown)

b. Side mounted, on a flat vertical surface of the enclosure,

with the compressed air inlet pointing upward, or with the

stainless steel shroud facing downward to the floor.

1. Position the Vortex A/C on the top or side of your enclosure

so that there is sufficient clearance for the internal mechanical

thermostat and cold air outlet, and, so that the entire mounting

“footprint” of the Vortex A/C is supported by the enclosure.

(A 4-3/4” wide x 3-3/8” deep (121 mm wide x 86 mm deep) area).

Position the unit so that the metal shroud on the back of the

Vortex A/C is away from personnel, if possible. Also, position so

that no internal enclosure components obstruct air flow around

the mechanical thermostat.

2. Cut a 1-15/16” (49 mm) diameter hole (1-1/2” knockout size) in

the selected location on the enclosure. De-burr any sharp edges

around this hole.

3. Remove the 1-1/2” electrical locknut from the Vortex A/C. Insert

the threaded portion of the Vortex A/C into the 1-15/16” (49 mm)

hole in the enclosure. (Be careful not to damage the mechanical

thermostat during installation.)

4. From inside the enclosure, screw the electrical locknut onto

the threads of the Vortex A/C. Tighten the locknut securely to

compress the 1/8” (3 mm) thick sealing gasket that is positioned

between the enclosure and the Vortex A/C.

5. Determine a suitable location for the Cold Air Muffler inside the

enclosure that is close to the cold air outlet of the Vortex A/C.

(You will need a surface area of approximately 2” x 9” (50 mm

x 229 mm) to mount the muffler. The Muffler can be mounted in

any orientation, horizontal or vertical.) Using the supplied Muffler

Mounting Clamp (with double sided tape), attach this Clamp at

the desired location. Clean the mounting surfaces so that the

double sided tape bonds securely. If desired, this Clamp can

be permanently mounted to the enclosure using the supplied

mounting hardware. Two 5/32” (4 mm) diameter holes positioned

on 3/4” (19 mm) centers must be drilled to mount the Muffler

Clamp. Use the plastic snap rivets to secure the Muffler Clamp

to the panel.

6. Snap the Cold Air Muffler into the Mounting Clamp.

7. Cut a sufficient length of the 1/2” (13 mm) inside diameter vinyl

tubing from the supplied VADK124X Cold Air Ducting Kit to

connect the cold air outlet of the Vortex A/C to one of the hose

barbs on the Cold Air Muffler. Attach this length of vinyl tubing so

that it is free of sharp bends and kinks. Direction of cold air flow

through the Muffler is not important.

8. Attach all (or a portion of) the remaining supplied vinyl tubing

of the VADK124X Cold Air Ducting Kit to the opposite hose

barb connection on the Cold Air Muffler. Holes can be punched

or drilled into this 1/2” (13 mm) tubing to distribute the cold

air evenly inside your enclosure, or, the entire cold air output

can be directed to a heat sensitive component. If the end of

the 1/2” (13 mm) vinyl tubing is plugged, at least sixteen 1/8”

(3 mm) diameter holes should be punched into the tubing to

allow the cold air to escape. Use the nine self adhesive tubing

clips provided in the kit to mount the tubing.

9. Connect the compressed air filter (model VAAF15 or VAAF25)

to the compressed air inlet on the side of the Vortex A/C with a

length of 3/8” pipe. Install the compressed air filter as close as

possible to the Vortex A/C, in a location where the temperature

does not exceed 125

o

F (52

o

C). Allow the filter to hang at the

side of the enclosure as shown in the installation drawing. Use

a 13/16” (21 mm) wrench to hold the air fitting on the side of the

Vortex A/C stationary while tightening the pipe connections. Note

the air flow direction arrow on top of the filter.

10. Connect the compressed air supply to the inlet of the air filter.

See “Compressed Air Supply”.

OPERATION

Operate the Vortex A/C at 90 to 100 psig (6.2 to 6.9 bar) compressed

air pressure. Do not operate at pressures above 150 psig (10.3 bar).

Operation at pressures less than 90 psig (6.2 bar) and above 100

psig (6.9 bar) will effect the operation. When properly sized for

the application, the Vortex A/C will maintain the internal enclosure

temperature between 75-100°F (24-38°C). Enclosure temperatures

can momentarily reach 125°F (52°C) during initial start-up and after

long periods of inactivity. Variations in heat load and compressed

air conditions can effect thermostat operation. The mechanical

thermostat will regulate an internal valve to minimize compressed

air usage and maintain enclosure temperatures within the range

specified. In some applications, the Vortex A/C may run continuously

at lower air usage with the benefit of always keeping the enclosure

under slight internal pressure. In other applications, the Vortex A/C

may cycle on and off to maintain enclosure temperatures.

NOTICE:

The thermostat’s reaction to temperature change depends

on several factors: the internal and external heat loads, enclosure

size and proximity to the heat source. When the internal heat load is

zero (or very low) and when external temperatures are below 50°F

(10°C), the thermostat will take longer to react to air temperature

increases. There will be a lag between the rising air temperature and

when the thermostat reacts, which can result in temperatures inside

the enclosure exceeding 125°F (52°C). When air and thermostat

temperatures equalize, the reaction to temperature change is

improved and the lag is minimized.

CAUTION:

The rear metal shroud of the Vortex A/C becomes hot

during operation and can remain hot for a period of time after the

unit has cycled off. Note warning label precaution, and avoid direct

contact with this area of the unit during or after operation.

TROUBLESHOOTING

Insufficient cooling may be caused by the following:

1. Undersized compressed air line size.

2. Compressed air pressure at the product is too low.

3. Partial or complete blockage of internal compressed air paths,

due to dirt.

4. Water vapor in the compressed air supply.

5. Loose cold air outlet fitting. This may occur if not tightened

properly after being disassembled for cleaning.

If trouble persists, please contact nVent Hoffman for assistance,

phone #763.422.2211.

LIMITED WARRANTY

nVent Hoffman products will be replaced or repaired if found to be

defective due to manufacture within one year from the date of invoice.

nVent Hoffman makes no specific warranty of merchantability or

warrant of fitness for a particular purpose.

VORTEX A/C TYPE 4/4X

(SHOWN TOP MOUNTED ON CUSTOMER’S ENCLOSURE)

Hole 1-15/16” (49 mm)

1-3/4” (44 mm) diameter

x 3-19/32” (91 mm) long

muffler and mounting

clamps

Vent Air

Filter

5-7/8”

(149 mm)