04. 02. 20. Document Number 671712

4

Nuaire |

Western Industrial Estate

|

Caerphilly

|

CF83 1NA

|

nuaire.co.uk

SVT28

Installation Manual

6.0 ELECTRICAL INSTALLATION

Motors are totally enclosed and protected to IP55 (Dust and low

pressure water jets). Motors comply with BS5000, EN600034 and

IEC34-1. Enclosures are to IP55 with class H insulation. Motors are

tested in accordance with EN12101-3 2015.

Note the requirements for maintenance of the motor. Failure to

comply with the recommendations will invalidate any warranty

claim.

6.1 Wiring

Electrical supply wiring connection is to an externally mounted

terminal box on the case exterior. The box is pre-wired to the motor

with heat resisting cable. If a two speed starter is used it must have 3

contactors. Individual wiring diagrams are included with each unit.

A matched Nuaire Inverter Speed Control is available. Please contact

Nuaire.

6.2 Two Speed Motors

Two speed motors are supplied TAP or PAM single winding. All two

speed types are designed for Direct-On-Line (D.O.L) starting on both

speeds only unless otherwise specified

N.B. TAP wound motors require a three contactor control. Individual

wiring instructions are included with each unit.

6.3 Connection Details

Check that the voltage full load and starting current on the fan rating

label is suitable for your supply.

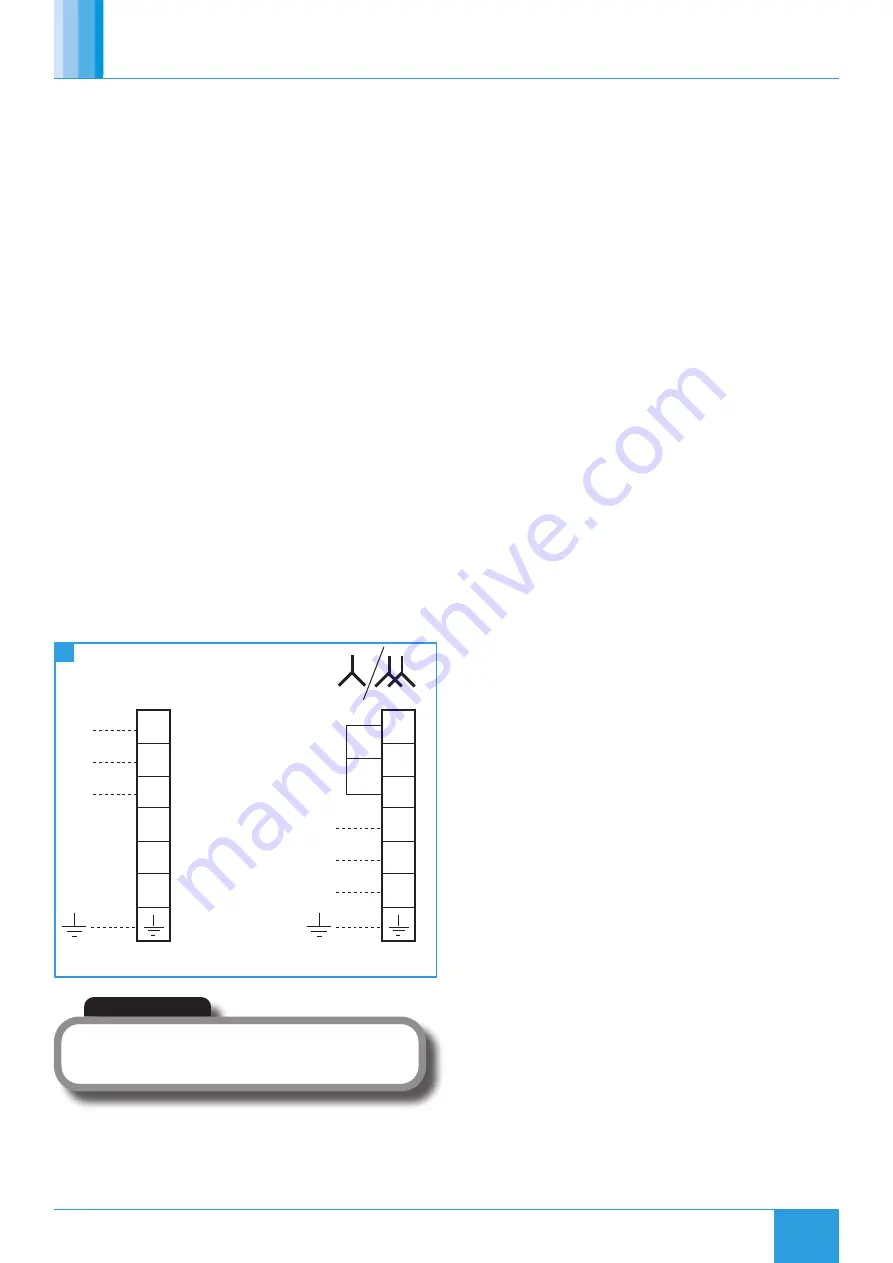

6.3.1 Two Speed - TAP/PAM WOUND MOTOR D.O.L Starting

(Both Speeds), 3 phase

1U

1V

1W

2U

2V

2W

400V 3 phase

50Hz supply

Link

(if no control

is used)

High speed

Low speed

L1

L2

L3

1U

1V

1W

2U

2V

2W

L1

L2

L3

6

Wiring - Three Phase - Two Speed TAP/PAM

Wound Motor D.O.L Starting (Both Speeds)

IMPORTANT

For good EMC engineering practice, any sensor cables or

switched live cables should not be placed within 50mm of

other cables or on the same metal cable tray as other cables.

6.4 Start Up Procedure

Ensure that the impeller rotation follows the label arrow indicator

on the casing. Should the direction be incorrect on three phase units,

reverse any two of the supply leads. Care should be taken to set correct

rotation as incorrect rotation may result in damage to the motor.

Equipment should be run for approx. 30 minutes to ensure correct

operation. If any fault occurs, the equipment should be switched off. Do

not re-start until the fault has been rectified.

7.0 SPECIFIC COMMISSIONING AND SERVICING

REQUIREMENTS

Motors for Smoke Extract Fans

Exposure temperature/time: 300°C for 2 hours / 400°C for 2 hours

These motors are used to provide a SAFETY FUNCTION for people

in the event of fire in public premises or in the home: they are

therefore subject to strict constraints concerning their operating and

maintenance.

Operating Constraints

i. Check on the nameplate that the selected motor corresponds to

the maximum exposure temperature and duration.

ii. Non ventilated motors MUST be placed in the airflow from the

driven fan. Ventilated motors can be placed outside the flow.

iii. AFTER THE MOTOR HAS BEEN SUBJECTED TO ONE EMERGENCY

DUTY OPERATION, IT MUST BE REPLACED.

iv. With variable speed control. Ensure that the maximum speed never

exceeds the speed of the motor supplied by the mains and that the

delivered power corresponds to the previous definitions.

These qualifications ensure the qualification of the driven fan by

the manufacturer.

Maintenance Constraints

Regular service visits must be performed on the installation AT

LEAST EVERY 6 MONTHS, incorporating the following checks:

i. Checking insulation resistance (R>100 MOhms, 500V DC)

•

If the drain holes are blocked, open them to eliminate any

accumulated condensation.

•

If R<100 MOhms, dry the stator in an oven and check the

insulation resistance. If the fault persists, replace the stator.

•

The stator must be replaced 5 years after installation or after

20,000 hours of operation.

ii. Cooling check

•

Ensure there is no dust or grease in the entire ventilation circuit

(housing fins, motor cover/fan if fitted driven fan).

•

Ensure the motor runs normally when switched on for a few

minutes.

iii. Bearing check (C3 or C4 play)

Run the motor during each maintenance visit. When the motor is cold,

a high level of noise is caused by the texture of the grease. This does

not indicate a bearing fault.

iv. S2 duty only:

The bearings must be replaced by an identical type every 5 years.

Ensure the motor runs normally when switched on for a few

minutes.

v. Fixing Check

During regular maintenance, check all fixtures and fittings to ensure

they have remained secure and in good working order.