N1100 Controller

NOVUS AUTOMATION

5/11

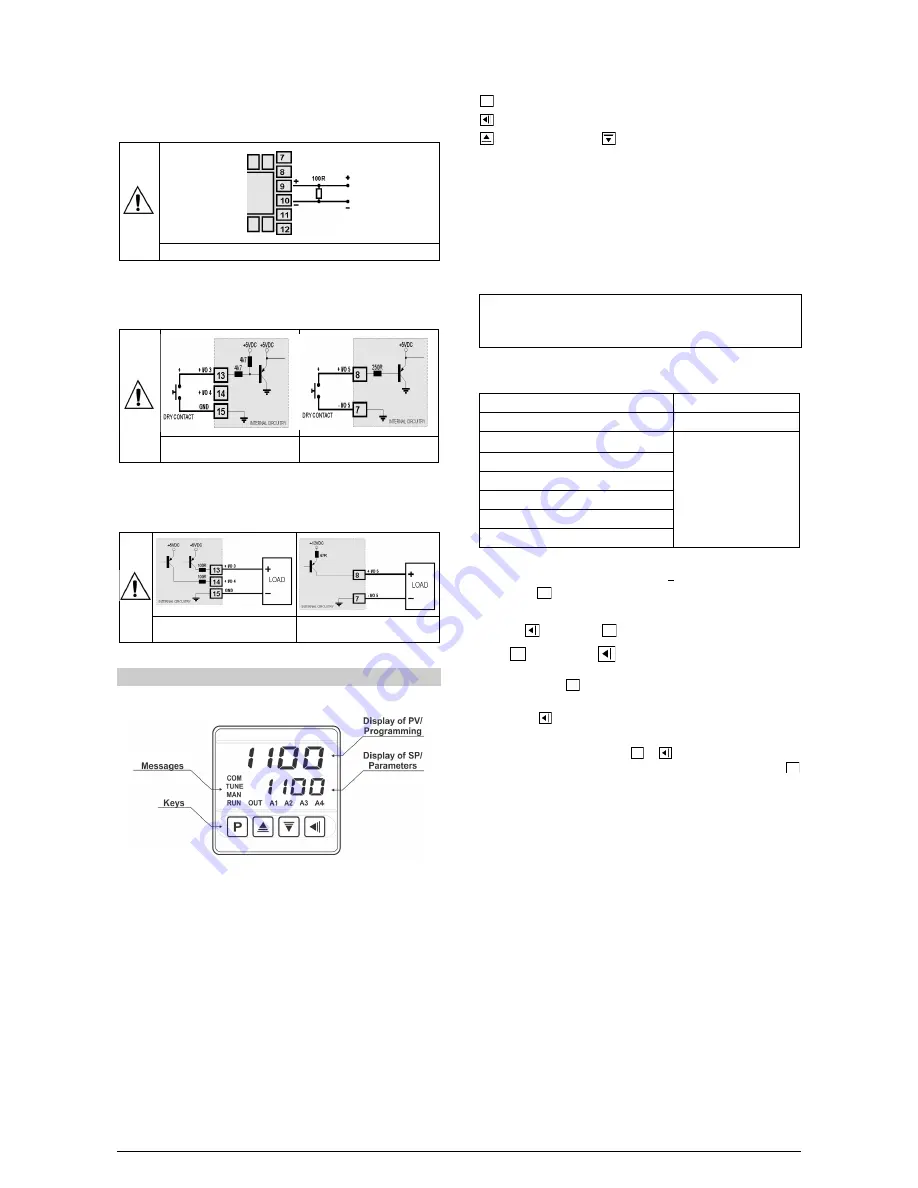

Remote Setpoint

Feature available in the controller's terminals 9 and 10. When the

Remote SP input signal is 0-20 mA or 4-20 mA, an external

100

Ω

shunt resistor of must be connected to terminals 9 and 10 as

indicated in Figure 4c.

Figure 4c – Connection for remote SP

Digital Input Connections

Figures 5a and 5b show switches (Dry Contact) driving I/O3 (or

I/O4) and I/O5.

Figure 5a – I/O3 or I/O4 as Digital

Input

Figure 5b – I/O5 as Digital Input

Connection of Outputs

The I/O channels, when configured as outputs, must have their load

limit capacities observed, according to the product specifications.

Figure 6a – I/O3 or I/O4 with output

pulse for SSR.

Figure 6b – I/O5 with output pulse

for SSR.

OPERATION

The controller's front panel, with its parts, can be seen in the Figure 7:

Figure 7 - Identification of the parts referring to the front panel

Display of PV/Programming: Displays the current value of PV

(Process Variable). When in configuration mode, it shows the

parameters names.

Display of SP/Parameters: Displays the value of SP (Setpoint).

When in configuration mode, it shows the parameters values.

COM indicator: Flashes to indicate communication activity in the

RS485 interface.

TUNE indicator: Stays on while the controller is in tuning process.

MAN indicator: Signals that the controller is in the manual control

mode.

RUN indicator: Indicates that the controller is active, with the control

output and alarms enabled.

OUT indicator: For relay or pulse control output; it reflects the actual

state of the output. If an analog output is assigned for control (0-20

mA or 4-20 mA), the OUT indicator lights continuously.

A1, A2, A3 and A4 indicators: signalize the occurrence of alarm

situation.

P

P Key used to walk through the menu parameters.

Back Key: used to retrocede parameters.

Increment key and

- Decrement key: allow altering the

values of the parameters.

When the controller is powered on, its firmware version is presented

for 3 seconds, after which the controller starts normal operation. The

values of PV and SP are displayed and the outputs are enabled.

In order to operate appropriately, the controller needs a configuration

that is the definition of each one of the several parameters presented

by the controller. The user must be aware of the importance of each

parameter and for each one determine a valid condition or a valid

value.

Note: Since many parameters depend on the input type chosen, it

is recommended that the parameter

TYPE

be the first one to be

configured.

The parameters are grouped in levels according to their functionality

and operation easiness. The 7 levels of parameters are:

LEVEL

ACCESS

1- Operation

Free access

2-

Tuning

Reserved access

3- Programs

4- Alarm

5- Scale

6- I/Os

7- Calibration

Tabele5 – Cycles of Parameters

The parameters in the operation level (1

st

level) are easily accessed

through the

P

key. The access deeper levels use the combination

of Keys:

(BACK) and

P

(PROG) pressed simultaneously

Press

to advance or

to retrocede parameters within a level.

At the end of each level, the controller returns to the operation level.

Keep pressing the

P

key to move fast forward in the level.

Alternatively, the controller returns to the operation level after

pressing the key for 3 seconds.

All configuration parameters are stored in protected memory. The

values are saved when the keys or are pressed after changing

a parameter value. The value of SP is saved upon pressing the

key or every 25 seconds.

P

P

P