DETAILED INSTRUCTIONS

(STEPS 1-6)

(Refer to photos on front page)

USING A RECEIVER BATTERY PACK

The Racer-EX does not require an external receiver battery pack

for most racing situations. Built-in Radio Priority Circuitry™

provides complete control of the steering servo even after the

main battery pack has "dumped" and can no longer provide the

power required to operate the motor. However, applications

using multiple high-powered servos, and/or main battery packs

with 8 or more cells require the use of an external receiver

battery pack to prevent overloading of the ESC’s voltage

regulator. Failure to use a receiver battery pack in these

applications may result in damage to the voltage regulator and

will void the product warranty.

1. Plug an external 5-cell nickel cadmium (1.2 VDC/cell) re-

ceiver battery pack into the battery slot of the receiver.

2. Leave the ESC’s ON/OFF switch in the OFF position. This

switch is not used with this configuration.

3. Use the ON/OFF switch on the external receiver battery

pack to turn the system power on and off.

STEP 5

TRANSMITTER ADJUSTMENTS

For proper ESC operation, the basic transmitter throttle adjust-

ments are:

HIGH ATV, EPA

—Controls the amount of throw from neutral

to full throttle.

Set to maximum setting.

LOW ATV/EPA/ATL

—Controls the amount of throw from

neutral to full brakes.

Set to maximum setting.

EXP

or

EXPO

—Controls the linearity of the throttle channel.

Set to zero or middle setting

.

SUB TRIM

—Usually used to center a servo.

Set to zero or

middle setting

.

TH TRIM or COAST BRAKE

—Controls

coast brakes of the ESC.

Set it to middle setting.

MECHANICAL ADJUSTMENT

—Adjusts throw of throttle trig-

ger.

Set the throw for 2/3 throttle, 1/3 brake.

THROTTLE REVERSING SWITCH

—

Set in either position.

Do

not change the setting after ESC Set-Up.

See ONE-TOUCH SET-UP NOTES on front page

If the factory-installed Futaba J style plug installed on the ESC is

not compatible with your receiver, follow Figures 1-3 to change

the input plug. The Novak Input Plug System

TM

will convert the

ESC's input plug for use with Airtronics, KO, Kyosho, & JR radios.

STEP 1

CHANGING THE INPUT PLUG

Airtronics (A)

KO

Kyosho (KYO)

JR*

*JR plug can be used in place of Airtronics "Z" Connector

FIGURE 3

Insert each pin into the correct plug slot. Each

pin should "click" into place.

CAUTION

Improper installation of these wires may cause

damage to the receiver, servo, and ESC.

0.1

µ

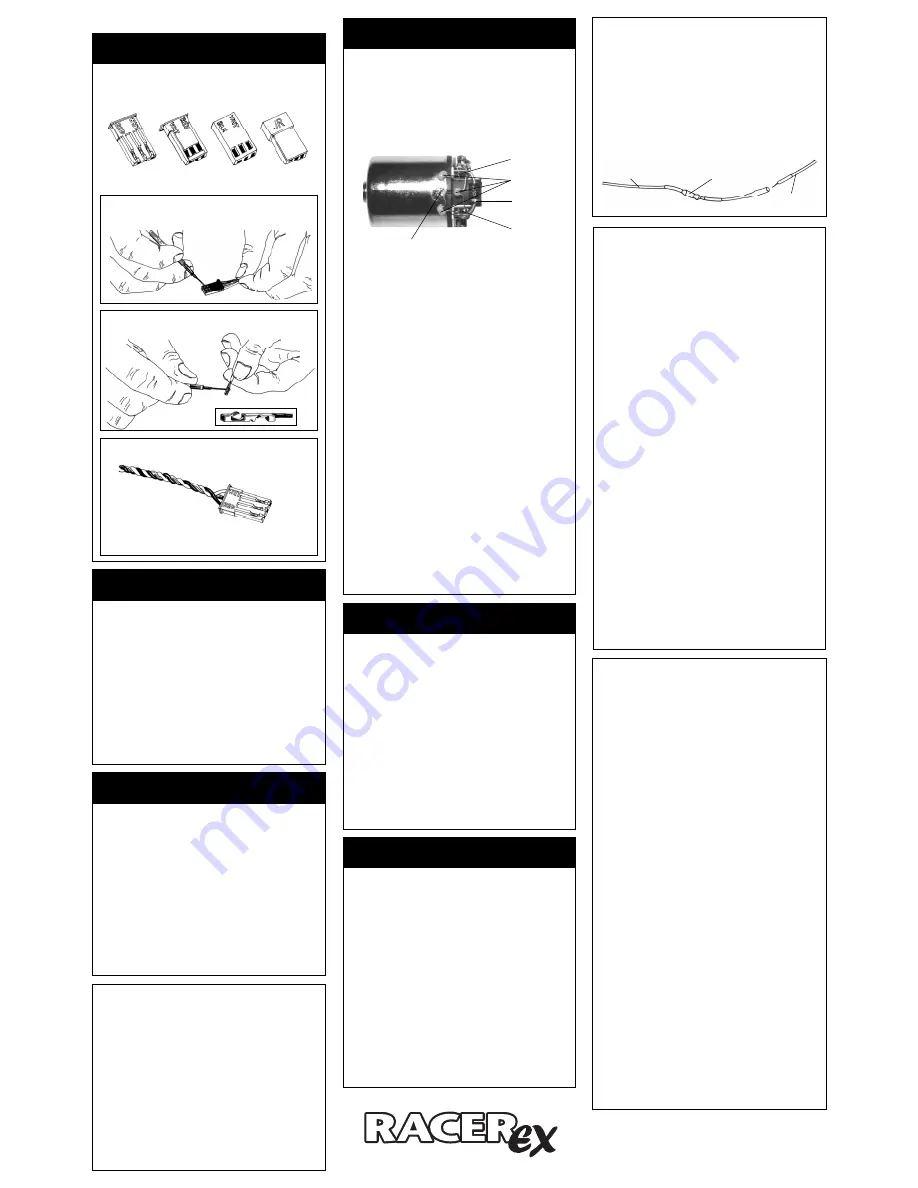

F Capacitors

Negative (-)

motor tab

Positive (+)

motor tab

Ground*

Schottky diode,

silver stripe

closest to (+).

1. INSTALLING MOTOR CAPACITORS

Motors generate ra-

dio noise that can cause radio problems.

Capacitors must

be used at all times on every motor to prevent damage

to the ESC.

Solder the included three 0.1

µ

F, 50 V, non-polarized, ce-

ramic capacitors between:

•

POSITIVE

(+) motor tab &

NEGATIVE

(-) motor tab.

•

POSITIVE

(+) motor tab &

GROUND

tab*.

•

NEGATIVE

(-) motor tab &

GROUND

tab*.

Extra 0.1

µ

F capacitors are available in Novak kit #5620

Extra Schottky diodes are available in Novak kit #5640

2. INSTALLING THE SCHOTTKY DIODE

Solder the included

Schottky diode between

POSITIVE

(+) motor tab &

NEGA-

TIVE

(-) motor tab. The diode is polarized and must be

installed with the silver stripe (+) closest to the POSITIVE

motor tab.

3. PLUGGING INTO THE RECEIVER

Plug the ESC into

CHANNEL 2 (or THROTTLE CHANNEL) of the receiver. Plug

the servo into CHANNEL 1. Nothing should be plugged into

the BATTERY CHANNEL.

4. BATTERY & MOTOR CONNECTIONS

Solder the included

extra piece of red wire from BATTERY POSITIVE (+) to

MOTOR POSITIVE (+).

Splice the ESC red wire into the extra red wire and insulate

the solder joint with heat shrink tubing.

Solder the ESC blue wire to MOTOR NEGATIVE (-).

Solder the ESC Black wire to BATTERY NEGATIVE (-).

5.

USING PLUGS FOR BATTERY & MOTOR CONNECTION

High-quality/low-resistance connector plugs, such as

Dean’s Ultra Plugs, can also be used to connect the

Racer-EX. While these connectors make component

changes quick and easy, the connection will never have

the low resistance of a good solder joint.

Use connectors that can not be connected backwards,

as this will damage the ESC and void the warranty.

It is good practice to use a female connector on battery

to keep from short-circuiting on conductive surfaces.

If you use connector plugs for battery and motor, use a

male connector on the ESC battery wires and a female

connector on the motor wires. Doing this, will avoid

plugging the battery into the motor output of the ESC.

STEP 4

HOOK-UP INSTRUCTIONS

*Stock motors do not have ground tabs, solder to the can of the motor.

STEP 3

MOUNTING INSTRUCTIONS

1. MOUNTING THE ESC

Use the included mounting tape to

mount the ESC in a location that provides maximum airflow

through the heat sinks. For off-road cars, the ESC should be

mounted on the chassis.

Mount the ON/OFF switch in a convenient place with a

piece of mounting tape or screw.

2. MOUNTING THE RECEIVER

To minimize glitching, mount

the receiver and antenna away from the ESC, motor, servo,

power wires, or any large piece of metal (such as a chassis)

or graphite.

If you must mount the receiver on the chassis, mount it on its

side with the crystal & antenna as far above the chassis as

possible to reduce the chances of radio interference.

Mount the antenna as close to the receiver as possible.

Follow the receiver manufacturer’s instructions for recom-

mended antenna routing and mounting.

STEP 2

HEAT SINK INSTALLATION

The included heat sinks will make the ESC run cooler and faster

when they are properly installed.

1. INSTALLING THE LARGE HEAT SINK

Place the ESC on a flat

surface and press the large heat sink onto the row of 5

transistors on the left side of the ESC.

2. INSTALLING THE SMALL HEAT SINK

Press the small heat

sink onto the row of 3 transistors on the right side of ESC.

The heat sinks should press onto the transistors with a

snug fit. If they are installed upside-down or shifted off-

center, the fit will be either too tight or too loose.

To prevent damage to the components under the transistors,

never use a vise or pliers to force the heat sinks onto the

transistors

. Do not use glue to attach heat sinks.

To prevent short-circuits,

never allow the heat sinks to

touch each other or any exposed metal or graphite.

The locking tab must not

extend outside the

plastic plug housing.

(Airtronics plug shown)

WHT

=

White wire (signal)

BLK

=

Black wire (negative)

RED

=

Red wire (positive)

FIGURE 1

Using a small standard screwdriver, press each

of the three metal locking tabs and remove each pin from

the plug.

FIGURE 2

Using the screwdriver, carefully bend each

of the metal locking tabs to the angle shown.

STEP 6

SPEED CONTROL SET-UP

Speed control should be connected to receiver and to a

charged battery pack, and the transmitter adjusted.

1. TURN ON THE TRANSMITTER

2. TURN ON THE SPEED CONTROL

3. PRESS AND HOLD SPEED CONTROL’S SET BUTTON

With transmitter throttle at neutral, press and hold the

ESC

SET

button until the status

LED

turns solid red

.

4. RELEASE ESC SET BUTTON WHEN LED IS RED

5. PULL TRANSMITTER TRIGGER TO FULL THROTTLE

Hold it there until the status

LED

turns solid green

.

NOTE: The motor will not run during programming even if

it is connected to the speed control.

6. PUSH TRANSMITTER THROTTLE TO FULL-BRAKE

Hold it there until the status

LED

blinks green

.

7. RETURN TRANSMITTER THROTTLE TO NEUTRAL

Status

LED

will

turn solid red

, indicating that throttle is

at neutral and proper programming has been completed.

Speed control is programmed & ready to race!

If transmitter settings are changed, it will be necessary to com-

plete the programming sequence once again.

If you experience any problems during programming, turn off

the speed control and repeat programming.

©1998 Novak Electronics, Inc. • All Rights Reserved

No part of these operating instructions may be reproduced without the written permission

of Novak Electronics, Inc.

All Novak ESCs are designed and manufactured in the U.S.A.

Racer-EX ESC, One-Touch Set-Up, Solid State RVP, Radio Priority Circuitry, CLC II, and Input

Plug System are trademarks of Novak Electronics, Inc.

Printed in the U.S.A. 6/98

IM-1750-2

FET SERVO CONNECTION

The Racer-EX is wired for connecting a FET Servo. This type of

servo requires a fourth wire connection. The fourth wire from

the servo is connected to the

small, blue 24-gauge silicone

wire

coming out of the ESC. In the Racer-EX, this wire supplies

6 volts of power to the servo and is controlled by the speed

control’s ON/OFF switch.

NOTE: Do not allow the blue FET servo wire to come in contact

with the chassis or battery terminal, as this may damage the

power switch, switch wires and the speed control’s PC board,

consequently voiding the product warranty.

If you experience radio glitching with the installation of the FET

servo, try installing a 10

µ

H inductor (usually supplied with

servo) in series with the blue wire.

Blue Wire from

speed control

10

µ

H inductor

Wire from

FET servo

TROUBLE-SHOOTING GUIDE

ESC Will Not Program Properly

• Too little transmitter throw––Increase ATV/EPA setting.

• Make sure ESC is plugged into the throttle channel of

receiver. Check throttle channel operation with a servo.

• ESC SET button not held long enough––Press and hold

SET button until status LED turns solid red.

• Make sure metal sockets on Input Harness are locked in

place in plastic plug.

• Check to be sure transmitter and receiver crystals are a

matched set

• Possible transmitter, receiver, or crystal problem.

Steering Channel Works But Motor Will Not Run

[Status

LED

is

solid RED

at all throttle positions]

• No signal from receiver––Make sure speed control is

plugged into throttle channel of receiver. Check throttle

channel operation with a servo. Check the wiring color

sequence & metal socket insertion of receiver harness.

Steering Channel Works But Motor Will Not Run

[Status

LED

is

RED at neutral

/

GREEN at full

throttle]

• Check motor connections. Check motor and brushes.

• Not programmed––Repeat programming.

• Thermal Shutdown––Allow to cool/Check for adequate

airflow through heat sinks.

• Check wiring and connections––Check operation of sys-

tem without speed control.

Receiver Glitches/Throttle Stutters During Acceleration

• Motor capacitors broken or missing––Refer to Step 4.

• Receiver or antenna too close to speed control, power

wires, battery, or motor––Refer to Step 2.

• Bad connections––Check wiring and connectors.

• Graphite or Aluminum Chassis––Refer to Step 2.

• Excessive current to motor––Use a milder motor or a

smaller pinion gear.

ESC Is Melted Or Burnt/ESC Runs With Switch Off

• Internal damage––Refer to Service Procedures.

*For more help call our Customer Service Department.

SERVICE PROCEDURES

Before sending your speed control in for service, review the

Trouble-Shooting Guide and Instructions. The speed control

may appear to need service when other problems exist in

the system such as a problematic transmitter, servo, battery,

connectors or motor.

PLEASE NOTE:

Speed controls that operate normally

when received will be charged a minimum service fee

and return shipping costs.

WHAT TO SEND: Fill out all of the requested information on

the enclosed

ESC SERVICE CARD

and return it with your re-

ceiver. Service cards can also be downloaded from our

website at www.teamnovak.com.

WARRANTY WORK: For warranty service work, you MUST

CLAIM WARRANTY on the

ESC SERVICE CARD

and include a

valid, dated, cash register receipt, or an invoice from previ-

ous service work. If any warranty provisions have been

voided there will be a service charge.

SERVICE COSTS: Customer is responsible for service costs

(parts, labor and shipping/handling charges). ESCs are

returned UPS/COD CASH ONLY. See

ESC SERVICE CARD

for

other payment and shipping options.

ADDITIONAL NOTES:

• Hobby dealers/distributors are not authorized to replace

speed controls thought to be defective.

• If a hobby dealer sends your speed control for service, sub-

mit a completed

ESC SERVICE CARD

to the dealer and make

sure it is sent with the speed control.

• Novak Electronics, Inc. does not make any electronic com-

ponents (transistors, resistors, etc.) available for sale.

• To provide the most efficient service possible to our cus-

tomers, it is not our policy to contact customers by

phone or mail.

FOR SERVICE, SEND ESCs TO:

Novak Electronics, Inc.

Attn: Service Department

18910 Teller Ave., Irvine, CA. 92612 USA

CUSTOMER SERVICE HOURS (PST):

M-Th: 8am-5pm; F: 8am-4pm (Closed every other Friday)

(949) 833-8873 • FAX (949) 833-1631

Visit us at www.teamnovak.com