6

2. Clearly identify and mark each incoming line with its

respective well (using colored tape and/or numbers).

notE:

Group all vapor lines together and all liquid lines

together for runs through common trenched or walled areas.

Do not mix vapor lines and liquid lines together, even when

individually insulated, as this may contribute to a “short-

circuiting” of heat transfer. Make sure the lines are all marked

and recorded for future reference. The installing contractor

should keep a copy of the location/distances sketch, and

give a second copy to the property owner.

3. Remove the top and front cover of the compressor unit. Pipe

connections, and electrical line access holes, are labeled

on the exterior right hand side of the compressor unit.

• The top two lines go to the air handler.

• The lower two lines go to the borehole.

• Insulate all such exposed hot gas refrigerant tubing with

at least a 220° F rated 3/4 inch thick wall insulation, such

as Armaflex, Rubatex, or Neoprene.

4. Place the compressor unit as close to the air handler as

reasonably possible to limit line set distances. See

line set sizing Between compressor unit &

air handler

For line set sizing between the compressor and air handler

(or other interior heat exchanger), see

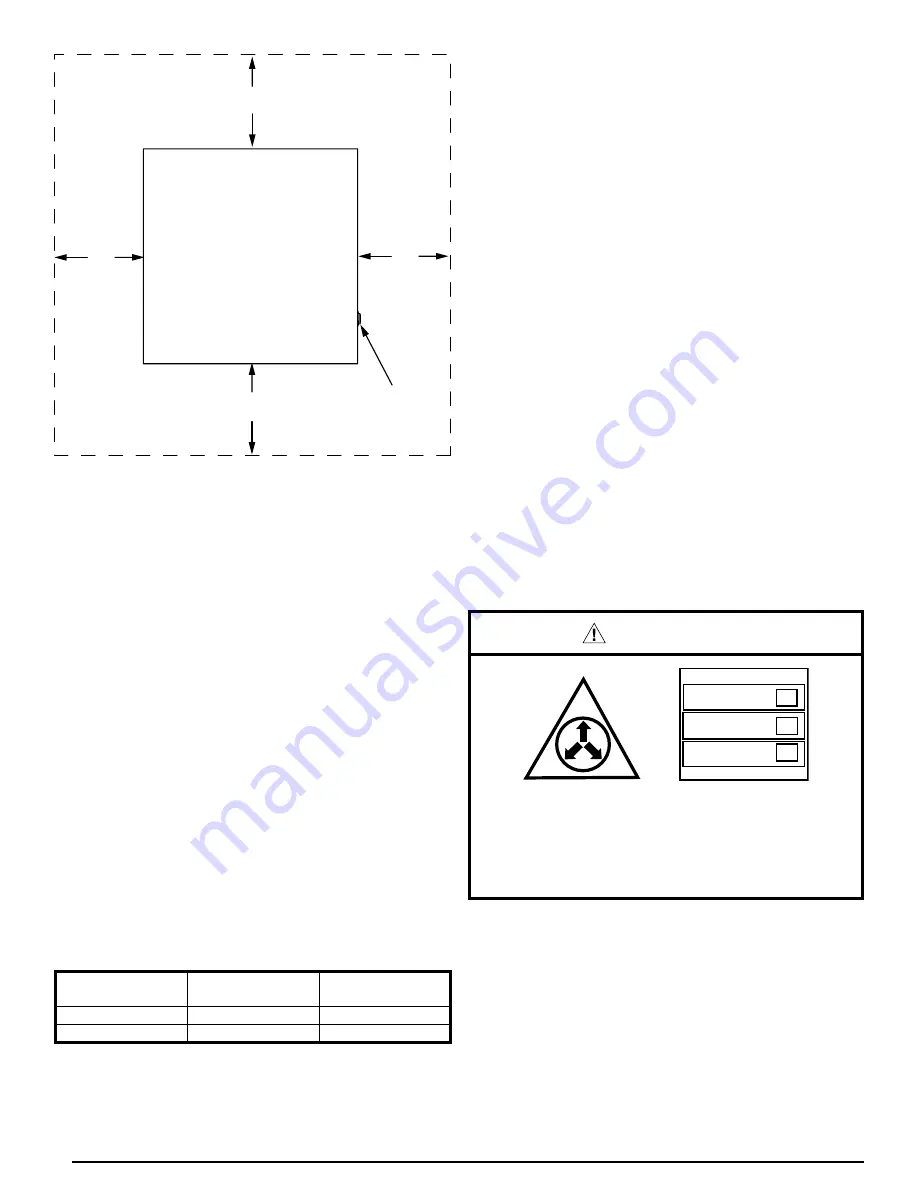

18”

18”

18”

18”

FRONT

REAR

LEFT

SIDE

RIGHT

SIDE

LINESET &

ELECTRICAL

HOOKUPS

GEOTHERMAL

UNIT

NOTE:

Allow 36” clearance from top of unit

Figure 1. service clearances for Interior &

Exterior installations

coMPrEssor

sIzE (Btu)*

lIQuID

lInE

VApor

lInE

24,000 - 36,000

1/2 inch O.D.

3/4 inch O.D.

48,000 - 60,000

1/2 inch O.D.

7/8 inch O.D.

*Compressor size is the actual compressor size in the compressor unit box,

not maximum system capacity, system size, or air handler size.

table 1. line set sizing between the compressor

unit & air handler

Insulating Interior line sets

Insulate all interior refrigerant lines and their connections. The

compressor section contains the expansion valve and the

liquid line is more likely to “sweat” as it condenses moisture

from the interior air.

Use at least a 3/4 inch wall closed-cell insulation that is

non-corrosive to copper to insulate all refrigerant lines. Use

Armaflex, Neoprene, or Rubatex having at least a 220° F

temperature rating for all interior vapor refrigerant lines, and

for all interior liquid refrigerant lines, use Tubolit, Armaflex,

Neoprene, or Rubatex having at least a 180° F liquid refrigerant

temperature rating.

IMPortant notE:

leave an air gap between the insulated vapor refrigerant

line and the insulated liquid refrigerant line wherever

possible. Do not tightly tape or wire tie the insulated lines

together. this will short circuit the heat transfer prior to

the primary heat transfer design areas in the air handler

and in the ground.

use Isolationtype hangers

Isolate the interconnecting refrigerant tubing from the framing

and/or from the duct work, as well as from where refrigerant

tubing runs through stud spaces, enclosed ceilings, or pipe

chases, etc. Use isolation type hangers, since rigid fastening

transmits noise to the structure.

Brazing

Installation of equipment will require brazing operations.

Installer must comply with safety codes and wear appropriate

safety equipment (safety glasses, work gloves, fire extinguisher,

etc.) when performing brazing operations.

WarnInG:

NITROGEN

HEALTH

FLAMMABILITY

REACTIVITY

0 Minimal Hazard

1 Slight Hazard

1

0

0

When purging the system with nitrogen, avoid direct

face exposure or contact with valve when gas is

escaping. always ensure adequate ventilation is

present during the depressurization process. any

uncertainties should be addressed before proceeding.

IMPortant notE:

to prevent internal oxidation and scaling from occuring,

braze all connections with dry nitrogen flowing through

the joints.