10

Conventional Furnaces - Unconfi ned Spaces

An unconfi ned space is an area including all rooms not

separated by doors with a volume greater than 50 cubic

feet per 1,000 Btuh of the combined input rates of all

appliances which draw combustion air from that space.

In general, a furnace installed in an unconfi ned space will

not require outside air for combustion. However, in homes

built for energy effi ciency (low air change rates), it may

be necessary to provide outside air to ensure adequate

combustion and venting, even though the furnace is located

in an unconfi ned space.

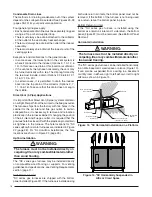

WARNING:

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected to the venting system

being placed into operation could result in carbon monoxide poisoning or death.

The following steps shall be followed with each individual appliance connected to the venting

system being placed in operation, while all other appliances connected to the venting system

are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal pitch, as required in the

National

Fuel Gas Code, ANSI Z223. 1/NFPA 54 or the CSA B149.1, Natural Gas and Propane Installation

Codes

and these instructions. Determine that there is no blockage or restriction, leakage,

corrosion and other defi ciencies which could cause an unsafe condition.

3. As far as practical, close all building doors and windows and all doors between the space

in which the appliance(s) connected to the venting system are located and other spaces

of the building.

4. Close fi replace dampers.

5. Turn on clothes dryers and any appliance not connected to the venting system. Turn on

any exhaust fans, such as range hoods and bathroom exhausts, so they are operating at

maximum speed. Do not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being inspected into operation. Adjust

the thermostat so appliance is operating continuously.

7. Test for spillage from draft hood equipped appliances at the draft hood relief opening after

5 minutes of main burner operation. Use the fl ame of a match or candle.

8. If improper venting is observed during any of the above tests, the venting system must

be corrected in accordance with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or

CSA B149.1, Natural Gas and Propane Installation Codes

.

9. After it has been determined that each appliance connected to the venting system properly

vents when tested as outlined above, return doors, windows, exhaust fans, fi replace

dampers and any other gas-fi red burning appliance to their previous conditions of use.

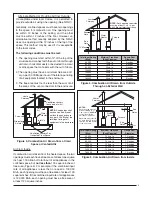

Direct Vent Furnaces

Direct Vent (2-pipe) furnaces draw combustion air directly

from the outdoors and then vent the combustion products

back outside, isolating the entire system from the indoor

space. It is important to make sure that the whole system

is sealed and clearances to combustibles are maintained

regardless of the installation being in a confi ned or

unconfi ned space.

Example

:

A space with a water heater rated at 45,000 Btuh

input and a furnace rated at 75,000 Btuh requires a

volume of 6,000 cubic feet [50 x (45 + 75) = 6,000] to

be considered unconfi ned. If the space has an 8 foot

ceiling, the fl oor area of the space must be 750 square

feet (6,000 / 8 = 750).