28

Removing The Burner Orifices

1. Adjust the thermostat to the OFF position, or its lowest

temperature setting.

2. Turn the main gas supply valve (on the outside of the

unit) to the OFF position.

3. Turn off all electrical power to the furnace.

4. Remove the door from the burner compartment. See

5. Turn the gas valve ON/OFF knob (1) to the OFF position.

CAUTION:

It is good practice to label all wires prior

to disconnection. Wiring errors can cause

improper and dangerous operation.

6. Disconnect the wires from the terminals (2).

7. Remove the supply gas piping from the gas valve inlet

(3).

8. Remove four screws (4) securing the gas manifold

assembly (5) to the burner assembly (6).

9. Set aside the screws (4) and remove the gas manifold

assembly (5) from the burner assembly.

WARNING:

Do not attempt to drill the gas orifices. Use only

factory supplied orifices. Improperly drilled

orifices may cause fire, explosion, carbon

monoxide poisoning, personal injury or death.

10. Carefully remove the burner orifices (7) from the gas

manifold assembly (5).

11.

Read the rating plate affixed to the appliance to

determine its rated input (Btu/hr) and the size of the

factory installed orifices. NOTE: Natural Gas furnaces

may be equipped with one of three orifices.

WARNING:

Do not use Teflon tape or pipe joint compound

on the orifice threads. The hole in the orifice

may become blocked and cause fire, explosion,

property damage, carbon monoxide poisoning,

personal injury, or death.

IMPORTANT NOTES:

• Before installing an orifice, check the face or side

of the orifice for the drill number to ensure that it

is the appropriate size.

• To prevent cross threading, screw the orifices (7)

into the gas manifold assembly (5) by hand until

snug, then tighten with a wrench.

12. Install the appropriate LP/Propane orifices (7) into the

gas manifold assembly (5).

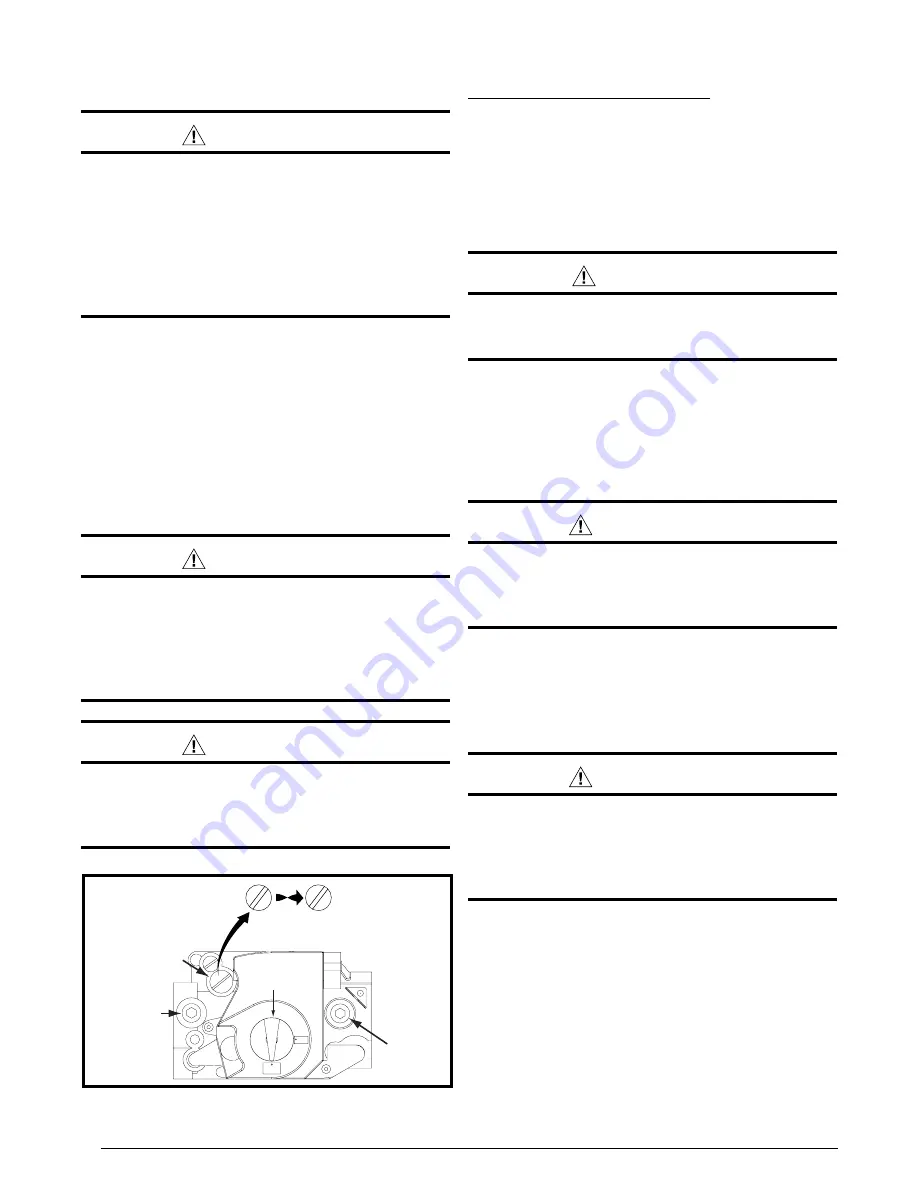

13. Remove the pressure regulator cap (

) from

the gas valve.

Conversion to LP/Propane

WARNING:

This furnace was shipped from the factory

equipped to operate on natural gas. Conversion

to LP/propane gas must be performed by

qualified service personnel using factory

supplied conversion parts. Failure to use the

proper conversion kit can cause fire, explosion,

property damage, carbon monoxide poisoning,

personal injury, or death.

This furnace can be converted from factory-equipped

natural gas to Liquid Propane gas. Conversion of this

valve requires replacement of the burner orifices on the

manifold assembly and flipping the regulator cap to the

side marked LP. See

below. The orifices required

for conversion are supplied with the furnace.

For altitudes between 0 and 1,999 feet, only the orifice is

changed. Altitudes between 2,000 and 10,000 feet require

both the orifice and regulator pressure to be changed.

See

to determine the correct orifice

size and manifold pressure to use at different altitudes.

WARNING:

Shut off the gas supply at the manual gas shutoff

valve, before disconnecting the electrical power.

A fire or explosion may result causing property

damage, personal injury or loss of life. Failure to

follow the safety warnings exactly could result

in serious injury, death or property damage.

WARNING:

To avoid electric shock, personal injury, or death,

turn off the electric power at the disconnect

or the main service panel before making any

electrical connections.

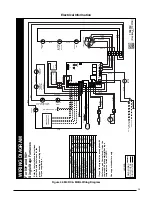

Figure 36

ON

OFF

IN

N

A

T N

A

T

L

P

L

P

Other side

of cap

Pressure Regulator

Cap

Manifold

Pressure Plug

Inlet Pressure

Plug

ON/OFF

Knob

OR

Figure 36.

Gas Valve - Top View

Содержание M4RC-072D-35C

Страница 47: ...47...