28

8. Hot Surface Ignition System

Model M1M

SEQUENCE OF OPERATION M1M SERIES

Call for heat: the thermostat calls for heat by energizing the

“W” terminal. The control checks to see the pressure switch

is open. If the pressure switch is closed when the call for heat

occurs, the control will begin to flash “3” on the Status LED

after 10 seconds and wait indefinitely for the pressure switch

to open.

Pressure switch proving: the control energizes the induced

draft motor and waits for the pressure switch to close. If the

pressure switch does not close within 10 seconds of the

inducer energizing, the control will begin to flash “2” on the

Status LED and wait indefinitely for the pressure switch to

close.

Pre-purge: the control runs the inducer for a 45 second pre-

purge time.

HSI warm up: the control energizes the HSI for 30 seconds.

The inducer remains energized.

Ignition activation period: the control energizes the main gas

valve for 6 seconds. The inducer and HSI remain energized.

Flame proving: the control de-energizes the hot surface

ignitor. The gas valve and inducer remain energized. If flame

is present 1 second after HSI de-energizes, the control goes

to blower on delay. If a flame is not present, the control de-

energizes the gas valve and proceeds with ignition retries as

specified below.

Blower on delay: If flame is present, the control energizes the

blower on HEAT speed 30 seconds after the gas valve

opened (24 seconds from HSI off). The gas valve and inducer

remain energized.

Steady heat: Control inputs are continuously monitored to

ensure limit and pressure switches are closed, flame is

established, and the thermostat call for heat remains.

Post purge: When the thermostat demand for heat is satisfied,

the control de-energizes the gas valves. The inducer output

remains on for a 30 second post-purge period.

Blower off delay: The indoor blower motor is de-energized

after a 120 second blower off delay. Blower timing begins

when the thermostat is satisfied.

COMPONENT PARTS

TROUBLESHOOTING

Polarity and Ground

The furnace will not operate if loss of ground occurs. Every

effort should be made at the installation to provide a good

ground. If old 2-wire romex exists it should be replaced with a

2-wire w/ground. A cold water line could be used provided that

the connection or grounding occurs before any di-electric

fittings and provided no plastic pipe is used inside or outside

the building.

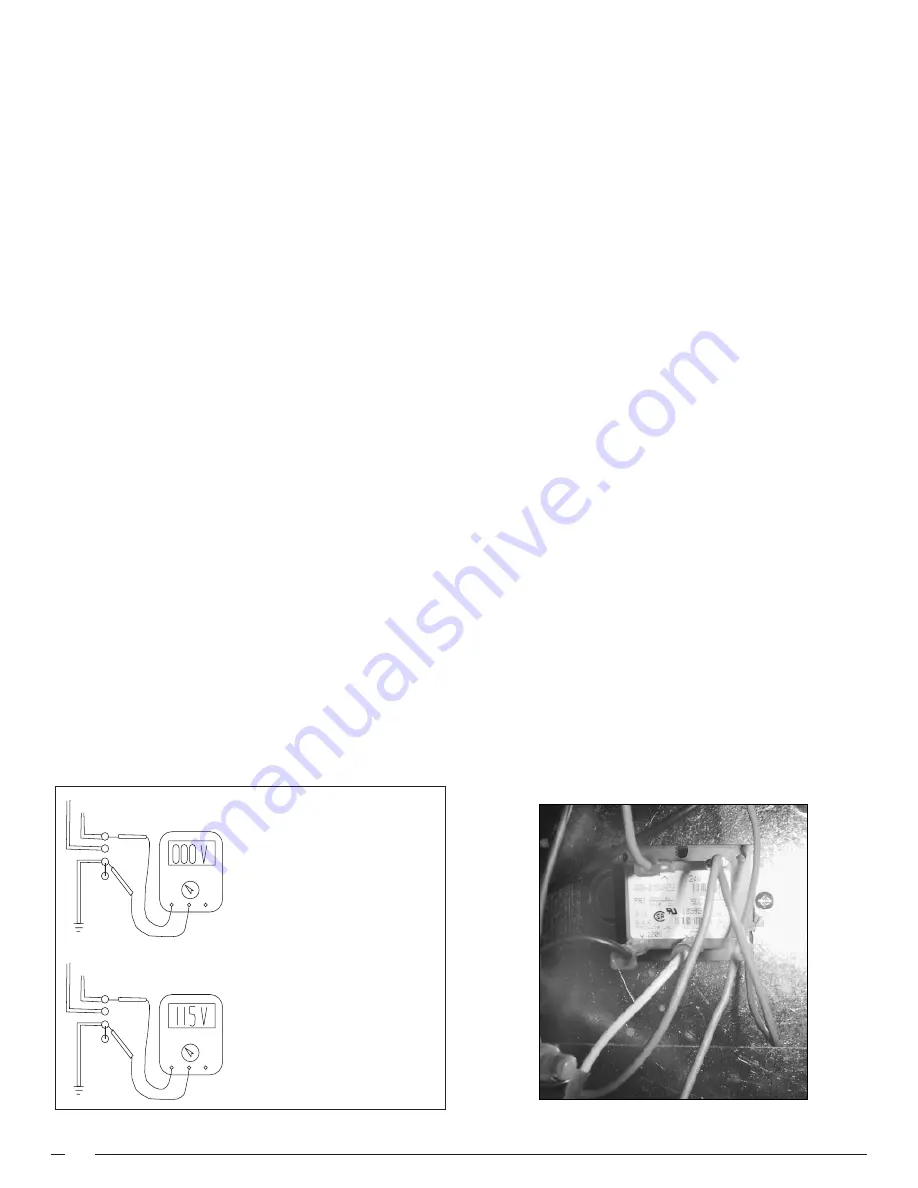

Transformer (See Figure 21) – The transformer supplies

control voltage (24 vac) by stepping down the supply (pri-

mary) voltage from 115 vac to 24 vac (secondary voltage).

Transformers are rated by VA. VA is the volt/amp or total

wattage the secondary can handle. When a transformer is

replaced the VA should be of an equal or greater value.

Check-out procedure:

1.

Using a volt/ohmmeter on at least 115 vac scale.

2.

Measure the voltage on the control board terminals

"XFMR" & "NEUTRAL".

3.

If voltage is 115 vac measure the voltage at terminals

marked "24 vac" & "Com" located in the center of the

control board.

4.

If 115 vac is measured at "XFMR" & "NEUTRAL" but no

voltage is present at "24 vac" & "Com" replace transformer.

GROUND

NEUT.

HOT

OK

VOLTS AC

VOLTS DC

OHMS

MICRO

AMPS

Volts

Com

Prep

GROUND

NEUT.

HOT

HOT NEUTRAL

VOLTS AC

VOLTS DC

OHMS

MICRO

AMPS

Volts

Com

Prep

Polarity may be verified as follows:

1. Turn power supply "ON"

2. Using a voltmeter, check for

voltage between the hot (black)

and neutral (white) wire of

supply circuit.

3. Reading should be Line (Supply)

Voltage.

4. Check for voltage between the

neutral (white) wire and ground

wire of the supply circuit.

5. Reading should be zero volts (if

line voltage is read, polarity is

reversed).

6. Double check by checking for

voltage between the hot (black)

wire and ground wire of the

supply circuit.

Figure 22. Polarity and Ground

Picture 11. M1M Transformer