25

Concentration of electrolyte

Volumeratio of water to

sulfuric acid

Capacity ratio of water to

sulfuric acid

1.100

9.80:1

5.84:1

1.200

4.33:1

2.36:1

1.270

2.80:1

1.57:1

1.280

2.75:1

1.49:1

1.400

1.90:1

1.00:1

After charging, close the vent plug , and it only can be put into use after its surface is cleaned clear.

Balanced charge

When in use, nonuniformity of voltage capacity, electrolyte and concentration may occur. Through

balanced charge, such nonuniformity can be eliminated, and all cells in the battery can be of uniform

conditions. Balanced charge is essential monthly for the batteries in use or following situation:

Cells whose discharge voltages are usually below the final voltage (1.7V/cell).

Cells with heavy discharge current (in circumstances where the drive motor and lift motor

operate synchronously with heavy load), or in circumstance with steep slope.

Cells not timely recharged after discharged.

Undercharged cells of cells not used for along time.

METHODS OF BALANCED CHARGE:

Normally charge the cells, when it is fully charged, shut off the charge power supply, keep it still for half

an hour, then switch on the power supply and continue to charge with the current of phase 2. When air

bubbles come out, convert to 1/2 of the current of phase 2 and continue to charge the cells, when air

bubbles are produced, shut off the charge power supply, keep is still for half an hour, then switch on the

power supply and continue to charge with 1/2 of the current of phase 2, until air bubbles are produced,

stop charging and left it still. Repeat the procedure for several times, until air bubbles are produced as

soon as power supply is connected. In balanced charge, voltage of each cell as well as the electrolyte

concentration should be measured and recorded. Before the charge is completed, the electrolyte

concentration and height should be adjusted to the prescribed parameters.

SULFURIC ACID FOR CELLS

Index name

Index

Sulphuric acid (H

2

S0

4

) %

≥

92

Ignition residue %

≤

0.03

Manganese (Mn) %

≤

0.0005

Ferrum(Fe) %

≤

0.005

Arsenic(As) %

≤

0.00005

Chlorine(Cl) %

≤

0.0005

Nitrogenoxides(calculatedby N) %

≤

0.0001

Ammonia salt (NH

4

) %

≤

0.001

Sulfur dioxide(S0

2

) %

≤

0.004

Copper (Cu) %

≤

0.0005

Deoxidized potassium permanganate (0) %

≤

0.001

Chorma ml

≤

1.0

Transparency mm

≥

160

Содержание CG1646

Страница 1: ...NOBLELIFT EQUIPMENT Service Maintenance Manual Power Sacker CG1646 V CG1646 01 00 Date 2011 2 10 ...

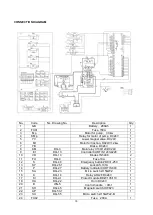

Страница 16: ...18 3 ELECTRIC SYSTEM 3 1 ELECTRIC DIAGRAM WIRING DIAGRAM ...

Страница 19: ...21 CG1646 Universal Electric Parts List ...

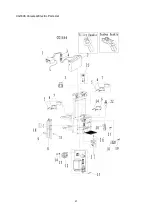

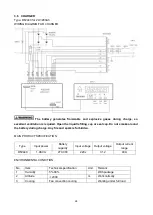

Страница 31: ...33 3 7 CURTIS CONTROLLER ...

Страница 50: ...52 5 DRIVE WHEEL 5 1 THE DRIVE WHEEL Driving Wheel MR250FR ...

Страница 64: ...66 9 2 TROUBLE SHOOT ...

Страница 65: ...67 ...