5

3-4. Short hose fittings

Do not fix a coupling directly on the tool. Make sure

that after a short hose is fixed with the Hose Nipple

R3/8X3/8 including in the accessories, then the

coupling be attached. If the couplings directly fixed,

it would be damaged by the vibration and the life

would be shortened.

4. PREPARATIONS

WARNING

Turn off the air supply and disconnect the air

supply hose before preparation for use.

4-1. Fixing the Attachment

(Fig.2)

Fix the Hose Nipple to the Bushing (M16XRc3/8) of

the tool.

+RVH1LSSOH

%XVKLQJ0 37

Fig.2

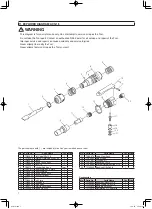

4-2. Replacing Chisels

ACH-16 (Fig.3)

(1) For fixing the chisel, pull the Sleeve aligning the

rectangular shaped groove on the chisel with the

Throttle Lever (180°reversed side is also OK.) and

push the chisel to the end and pull it slightly till

the Sleeve returns to the External Retaining Ring.

Then, if the Sleeve does not return, leave the hand

off the Sleeve and turn the chisel left - and - right,

or move it back and - forth. When the chisel comes

to the set - position, the Sleeve automatically

returns to the External Retaining Ring.

(2) For removing the chisel, pull the Sleeve and take

out the chisel.

&KLVHO

6OHHYH

3XOOWKH6OHHYH

7KURWWOH/HYHU

5HFWDQJXODUVKDSHGJURRYH

([WHUPDO5HWDLQLQJ5LQJ

5HWXUQ

Fig.3

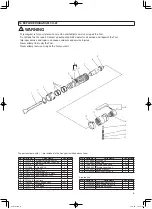

CH-24 (Fig.4)

(1) Rotate the Stop Ring to align the hole in the Stop

Ring with the Ball, the chisel can now be removed

or mounted.

(2) To mount the chisel, align the relief groove on the

shank with the Ball and insert the chisel until the

Ball restsin the relief groove; twist the Stop Ring

180˚ to secure the chisel.

%DOO

6WRS5LQJ

Fig.4

5. HOW TO OPERATE THE TOOL

WARNING

Do not operate tool at no load.

5-1.Start and Stop

(Fig.5)

(1) Before connecting to the air hose, make sure that

the Throttle Lever is in OFF

position.

(2) To start, hold the machine

and press the Throttle Lever.

(3) To stop, leave the hand off

the Throttle Lever.

5-2. Adjustment of Stroke

(Fig.6)

For ACH-16

Rotating the Adjust Valve

(adjusting air flow) by a flat

driver, the stroke can be

adjusted. The maximum

stroke can be obtained when

the groove on the Valve align

with the axis of the tool.

5-3. Operating Procedure

(Fig.7)

Grasp the Valve Body with one hand and place the

chisel to the work piece. Hold the Cylinder with the

other hand and press the Throttle Lever so that

the chisel starts lightly hammering the work piece.

Gradually press the lever harder to full operation

after the cutting position has been determined; this

will allow stable chipping work.

7KURWWOH/HYHU

Fig.5

$GMXVW9DOYH

0D[LPXP

0LQLPXP

Fig.6

ACH-16.indd 5

14.4.23 1:56:19 PM