GB

5

The TCB sensitive edge is made up of different materials, some of

which can be recycled, such as aluminium and electrical wires; oth-

ers must be disposed of as waste, such as the rubber profile.

1. To prevent inadvertent start-up of moving parts, disconnect the

automation from the electrical mains

2. Disassemble the sensitive edge by performing the procedure in

the section "Assembly and installation" in reverse order

3. As far as possible, separate all parts that can or must be recycled

or disposed of according to special procedures.

4. Sort and deliver the materials to authorised disposal firms as

envisaged by local legislation.

5) Disposal

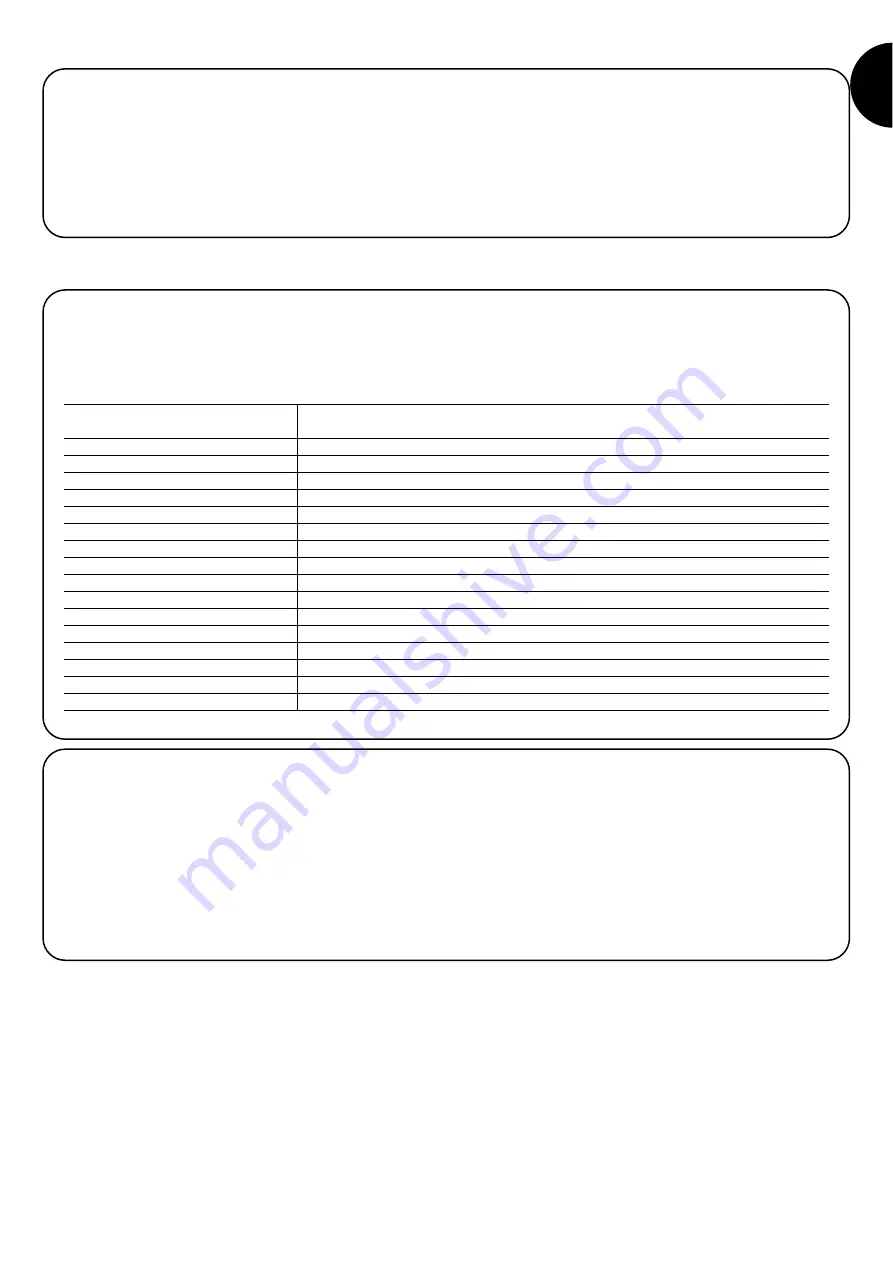

6) Technical specifications

With the aim of improving its products, Nice S.p.a reserves the right to apply modifications to technical specifications at any time without

notice, while maintaining the intended functions and use.

All technical specifications given below are referred to an ambient temperature of 20°C (±5°C)

TCB65 sensitive edge technical specifications

Type

Pressure-sensitive edge used as protective device (PSPE) to limit the force of automations on

auto matic gates or doors.

Sensitive profile materials

EPDM with switching chamber in conductive rubber

Safety class

class 3 according to standard EN 954-1

Sensitive profile length

10m

Mechanical stability

500N

Switching angle

±20°

Switching cycle duration

100.000

Operating temperature

-20 ÷ 55°C

Protection rating

IP 65 (correctly installed)

Nominal resistance in rest conditions

8200

Ω

± 500

Ω

Nominal resistance on activation

<1000

Ω

Maximum electrical limits

24V; 100mA

Resistivity

600

Ω

m/m

Maximum cable length

30m

Sensitive edge dimensions and weight

35x65 / 1200g/m

Aluminium profile dimensions and weight

35x14 / 380g/m

Overall dimensions and weight

35x79 / 1580g/m

Conformity to standards and certification

The TCB sensitive edge, assembled according to the instructions and complete with specific detection unit, has been certified by the man-

ufacturer at TÜV of Hanover D (Notified body 0032) as compliant with the following standards:

• EN 954-1 Machine safety – Safety related parts of control systems – General principles for design

• EN 1760-2 Machine safety – Pressure-sensitive protective devices - General principles for design and testing of pressure-sensitive edges

and pressure-sensitive bars

• EN 12978 – Industrial, commercial and garage doors and gates. Safety devices for power-operated doors and gates- Requirements and

test methods.