■

Insert a screwdriver and turn the pump rotor.

■

Screw in the venting screw.

■

Start FIGHTER 1127 and check that the circulation pump

functions.

It is usually easier to start the circulation pump with FIGHTER

1127 running, switch (8) in position ”

1

”. If helping the circu-

lation pump to start is performed with FIGHTER 1127 run-

ning, be prepared for the screwdriver to jerk when the pump

starts.

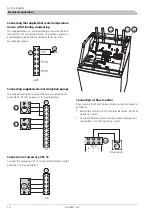

Indications

NOTE

Work behind panels secured by screws may only be

carried out under the supervision of a qualified install-

ation engineer.

Alarm lamp flashes and the text ”HP/MS–alarm”is dis-

played

AT HP/MP alarm: Set the motor protection to manual mode

and restart the heat pump.

Bad circulation in the heating medium circuit.

Cause:

Check the heating medium pump (16). Open any

radiator thermostats. Check that the particle filter

is not blocked.

Action:

If the alarm lamp still flashes the motor cut-out has tripped due

to the following causes.

Dropped phase or temporary mains disturbance.

Cause:

Check the fuses.

Action:

Overloaded compressor (27).

Cause:

Call qualified service personnel.

Action:

Mechanical fault on the compressor (27).

Cause:

Call qualified service personnel.

Action:

Defective motor protection (26).

Cause:

Call qualified service personnel.

Action:

Fine-wire fuse on relay card (29) has blown.

Cause:

Replace the fuse.

Action:

NOTE

The fault status must not be repeatedly reset, as there

is a risk of overheating the motor windings.

Alarm lamp flashes and the text ”LP–alarm”is displayed

Start up of cold installation

Cause:

Use ”Electric boiler mode”.

Action:

Bad circulation in brine system due to inferior ven-

ting/low pressure or ice (if ice has formed the brine

pump (35) will be warm).

Cause:

Vent and top up the fluid. Wait a few hours.

Action:

Brine pump (35) not running.

Cause:

Check the brine pump.

Action:

Lack of heating medium or other fault in the coo-

ling circuit.

Cause:

Call qualified service personnel.

Action:

Iced evaporator due to too low antifreeze concent-

ration.

Cause:

Check the brine’s freezing point.

Action:

After corrective action, in the display check that the differ-

ence between "

Brine In

" and "

Brine O

" is 2 – 5°C when

the compressor is operating. (See "Control –Information

available on the display", point 4.)

Once the fault cause has been rectified set switch (8) to ”

0

”

and then to ”

1

”.

Draining, heat medium side

Close the shut-off valves in heating medium system. Now

open the drain valve (76). A small amount of water runs out,

however, to fully empty the heating medium side requires

the connector that joins the heating medium side and the

connection on the heat pump ”HM-flow” to be loosened a

little to allow air to enter so the remaining water can run

out. When the heating medium side is empty the requisite

service can be carried out.

Draining, collector side

When replacing the brine pump or drive side or when

cleaning the pump, the shut-off valves in the brine system

should be closed. The hose between the top of the evapor-

ator and the brine pump is loosened on the evaporator. The

loose hose end can now be bent down and emptied in a

small bowl. Now loosen the connection to ”KB-in” a little

to allow air to enter so the heat pump’s brine side is emptied

completely. When the circuit is empty the requisite service

can be carried out.

If the operating disturbance cannot be rectified by means of the above, an installation engineer should be called.

FIGHTER 1127

32

Miscellaneous

Dealing with malfunctions

Содержание FIGHTER 1127

Страница 2: ...LEK LEK LEK LEK LEK LEK LEK LEK LEK LEK...

Страница 26: ...Electrical circuit diagram FIGHTER 1127 24 Miscellaneous Technical specifications...

Страница 27: ...25 FIGHTER 1127 Miscellaneous Technical specifications...

Страница 28: ...FIGHTER 1127 26 Miscellaneous Technical specifications...

Страница 29: ...27 FIGHTER 1127 Miscellaneous Technical specifications...

Страница 35: ......