6

FORM NO. L-20003-AC-0620

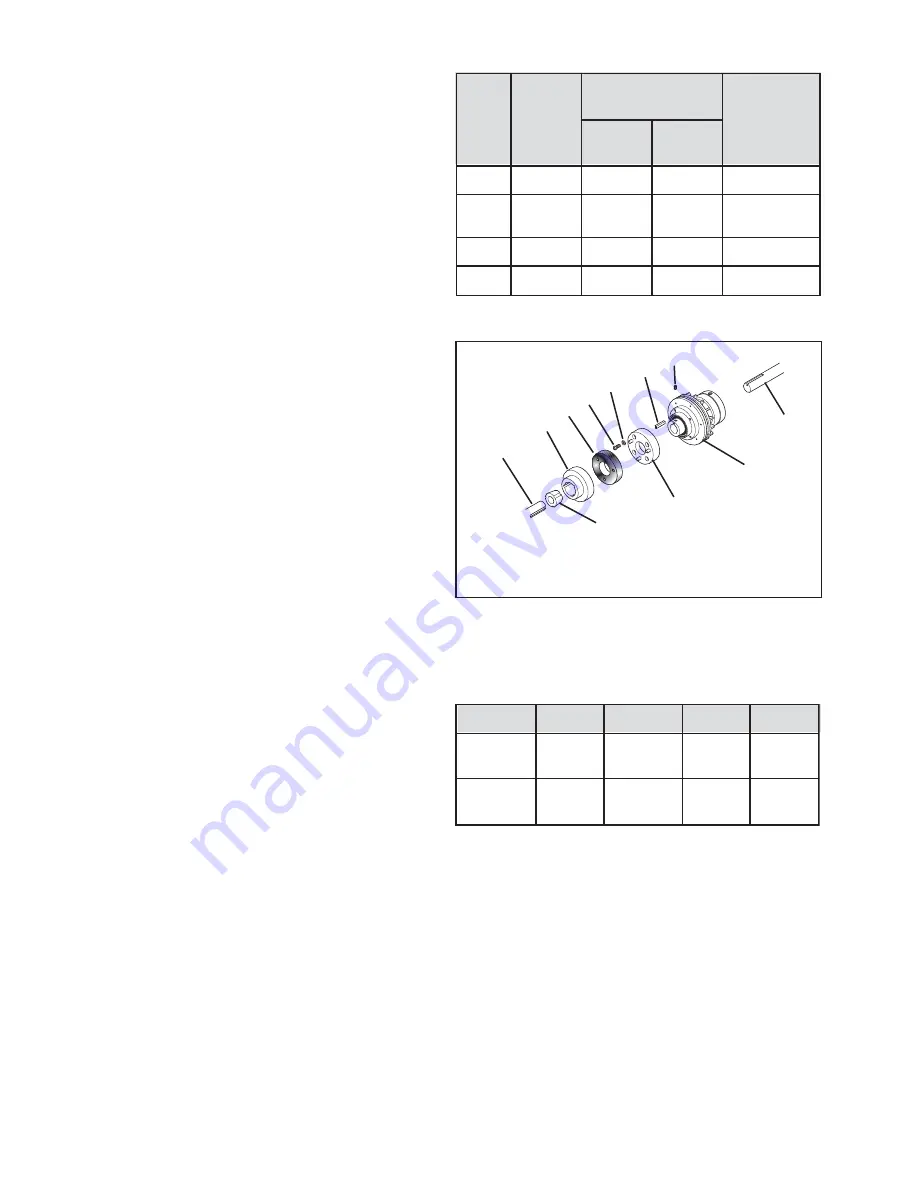

COUPLING MOUNT CLUTCH

Refer to Figure 1.

1. Determine the parallel misalignment of the shafts to

be coupled by placing a straight edge across the

shafts and measuring the maximum offset at various

points around the periphery of the shafts. Make the

necessary corrections to keep the shafts within the

parallel misalignment limits of the clutch coupling (See

Table 5).

NOTE: Before installation, the driving shaft can be fixed,

but the driven shaft must be allowed to float.

Align the air inlet port to the six o’clock down position

to allow condensation to drain out of the port.

2. Slide the Clutch onto the driving shaft until the end of

the Clutch is flush with the end of the shaft.

3. Insert the Key (Item 18) into the driving shaft and

Clutch.

4. Install and tighten the Set Screws (Item 17) to the

recommended torque (See Table 6).

5. Attach the Coupling Adapter Plate (Item 24) to the

Clutch pilot using Cap Screws (Item 33) and Lock

Washers (Item 34); then, tighten the Cap Screws to

the recommended torque (See Table 6).

6. Place the Coupling’s Flexible Disc (Item 25) over the

pins in the Coupling Adapter Plate (Item 24).

7. Insert the customer supplied Dodge

TM

Taper-Lock

Bushing into the Coupling Hub (Item 26).

8. Align the holes (not the threads) and slide the Dodge

TM

Taper-Lock Bushing/Coupling Hub Assembly onto the

driving shaft until it is flush with the shaft.

9. Thread the screws supplied with the Dodge

TM

Taper

Lock Bushing into the threaded holes of the Coupling

Hub (Item 26); then, alternately and evenly tighten the

screws to the bushing manufacturer’s specifications.

10. Align the pins in the Coupling Hub (Item 26) with the

holes in the Flexible Disc (Item 25).

11. Push the entire assembly together. Automatic spacing

is accomplished by spacers molded into the Flexible

Disc.

FIGURE 3

Driving

Shaft

Driven

Shaft

Dodge

TM

Taper-Lock

Bushing

26

25

33

34

24

18

17

Clutch

TABLE 5

L

E

D

O

M

E

G

D

O

D

M

T

K

C

O

L

-

R

E

P

A

T

C

S

I

D

-

Y

L

O

P

G

N

I

L

P

U

O

C

E

Z

I

S

N

O

I

T

A

I

R

A

V

D

E

R

U

S

A

E

M

T

R

A

P

A

°

0

8

1

S

T

N

I

O

P

T

A

T

A

O

L

F

L

A

I

X

A

M

U

M

I

N

I

M

(

M

O

R

F

E

U

L

A

V

D

E

D

N

E

M

M

O

C

E

R

L

A

I

T

I

N

I

)

G

N

I

C

A

P

S

L

E

L

L

A

R

A

P

M

U

M

I

X

A

M

R

A

L

U

G

N

A

M

U

M

I

X

A

M

W

F

.

n

i

8

/

5

-

2

}

m

m

5

7

.

6

6

[

.

n

i

5

1

0

.

0

]

m

m

1

8

3

.

0

[

.

n

i

0

4

0

.

0

]

m

m

6

1

0

.

1

[

n

i

8

/

1

+

]

m

m

5

7

3

.

1

+

[

W

L

.

n

i

4

m

m

6

.

1

0

1

[

.

n

i

5

1

0

.

0

]

m

m

1

8

3

.

0

[

.

n

i

4

6

0

.

0

]

m

m

5

2

6

.

1

[

n

i

8

/

1

+

]

m

m

5

7

3

.

1

+

[

W

M

.

n

i

7

m

m

8

.

7

7

1

[

.

n

i

5

1

0

.

0

]

m

m

1

8

3

.

0

[

.

n

i

2

1

1

.

0

]

m

m

5

4

8

.

2

[

n

i

8

/

1

+

]

m

m

5

7

3

.

1

+

[

W

H

.

n

i

8

]

m

m

2

.

3

0

2

[

.

n

i

5

1

0

.

0

]

m

m

1

8

3

.

0

[

.

n

i

8

2

1

.

0

]

m

m

1

5

2

.

3

[

n

i

8

/

1

+

]

m

m

5

7

3

.

1

+

[

TABLE 6

RECOMMENDED TIGHTENING TORQUES

L

E

D

O

M

W

F

W

L

W

M

W

H

W

E

R

C

S

T

E

S

)

7

1

M

E

T

I(

.

S

B

L

.

N

I

0

8

]

m

N

9

[

.

S

B

L

.

N

I

2

4

1

]

m

N

9

.

5

1

[

.

N

I

6

3

2

.

S

B

L

]

m

N

4

.

6

2

[

.

N

I

6

3

2

.

S

B

L

]

m

N

4

.

6

2

[

W

E

R

C

S

P

A

C

)

3

3

M

E

T

I(

.

S

B

L

.

T

F

1

2

]

m

N

5

.

8

2

[

.

S

B

L

.

T

F

1

2

m

N

5

.

8

2

[

.

S

B

L

.

T

F

3

2

]

m

N

2

.

1

3

[

.

S

B

L

.

T

F

8

7

]

m

N

8

.

5

0

1

[