9

•

Never touch moving parts on the roll cutter.

•

Attach safety instructions - pictograms - to the roll cutter so that they are clearly legible.

•

Only work in good lighting.

•

Before starting work, check the safety devices on the roll cutter and ensure

that they are functioning correctly.

•

Do not work on the roll cutter if you are tired.

•

Damaged parts on the roll cutter may only be replaced by authorized

personnel. Only use original parts.

•

Turn off the roll cutter in case of strong vibration, noise or other unusual

signs and inform the supervisor.

•

Do not wear loose clothing (e.g. a tie) or long hair to prevent them from

getting caught between rotating parts of the roll cutter.

•

Always stand firmly on the floor when working on the roll cutter.

•

Take special care after switching on and starting up the roll cutter.

•

Switch off the machine immediately and inform the supervisor if, while

working on the roll cutter, damage to the insulation, a burning smell or a

loud disturbing noise occurs, the machine jerks after switching on, individual

parts on the electrical system are overheated, sparks occur or electric

current can be felt.

•

If such hazards occur or if there is danger to the operator, switch off the roll

cutter by pressing the emergency STOP switch.

•

If someone recognizes that the operator of the roll cutter is in danger, they

can press the emergency STOP switch.

11.

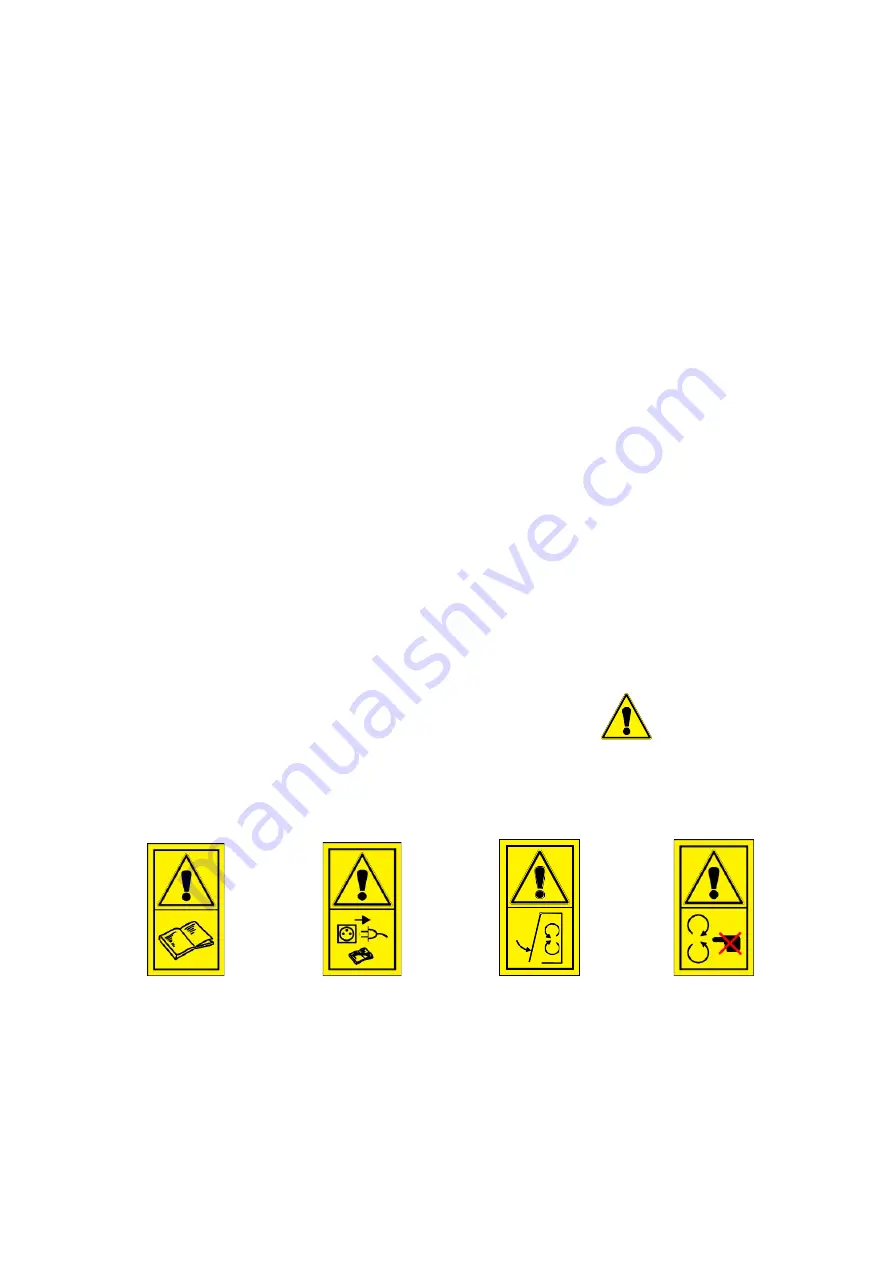

SAFETY INSTRUCTIONS ON THE NESCHEN ROLL CUTTER

The pictograms must be clearly legible on the CUTTER at all times.

Damaged pictograms must be replaced.

Pictograms and their meaning

. Safety pictograms on the roll cutter indicate

risks, as do the warnings in this operating manual.

The operator

must read the

safety

instructions.

Disconnect the

power supply

before repair work,

adjustments,

cleaning and

maintenance of

the roll cutter.

Close all covers

correctly before

commissioning.

Do not touch any

moving parts on

the roll cutter.