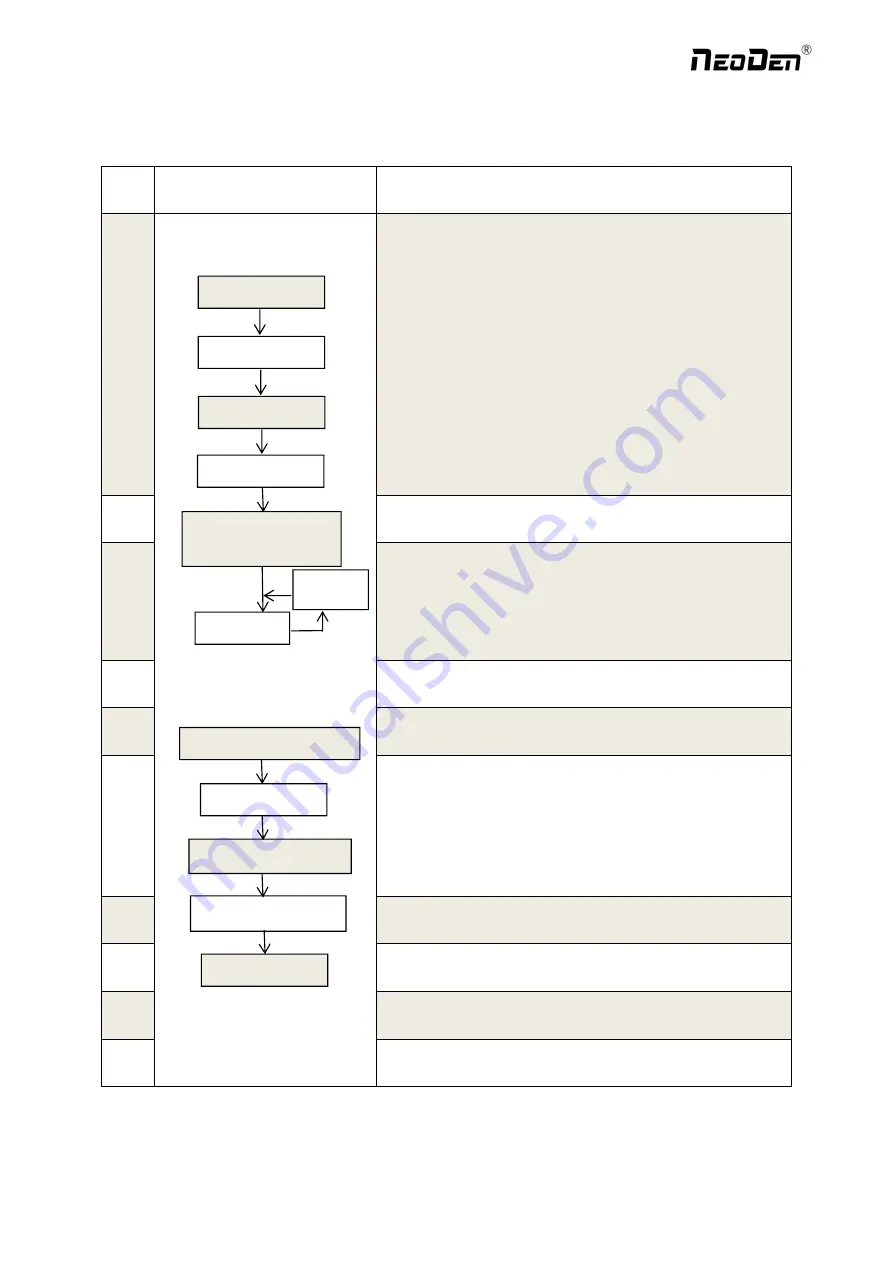

1.5 Operation flow chart

NO.

Flow chart

Note

1

1. The pick and place machine is a precision equipment. In the

installation position of the machine, it is necessary to carry out horizontal

correction before and after the equipment to prevent the uneven operation

of the equipment from damaging the service life of the equipment;

2. Connect and fix the equipment interface before and after the

equipment, and connect and fix the ground wire;

3. The access power must meet the requirements of power identification;

4. No less than 0.6mp air source input and adjust the pressure value to

OK;

5. Check the safety of the working area of the mounting head;

6. The XY transmission parts are not fastened and interfered, and check

that the emergency stop switch is in normal state;

2

Power on and turn the power switch clockwise;

3

1

,

1. When the self-test is carried out, the head indicator light of the

mounting head and the light source of the IC camera will be on and

flash briefly to indicate that the self-test is normal;

2

,

XY initialization (origin reset) is normal, the software enters the file

list interface, and no error report pops up;

4

After power on, directly enter the file list page;

5

See page 10 for the introduction of machine operation for

details;

6

Suggestions on production process:

1. First component confirmation: confirm the component angle

and polarity, component picking position and mounting

position;

2. Start production after confirming solder paste printing and

temperature setting;

7

Production process;

8

After the production is finished, reset the origin and prepare to

shut down;

9

Shut down the system via computer, then power off the

machine.

10

Disconnect the electricity supply after the system being

powered off.

Software shut down

System shut down

Power OFF

Exit

Production Finished

Preparation

Power ON

Automatic Test

Power on page

Program and Edit;

Production

Shutdown steps

Mounting

Modify

Abnormal

Start-up steps

9

Zhejiang

NeoDen Technology Co.,Ltd.

Содержание K1830

Страница 6: ...1 3Working Area Structure Figure 3 Top view of main mounting area 6 Zhejiang NeoDen Technology Co Ltd ...

Страница 7: ...Figure 4 X axis Beam Figure 5 Main Placement Head Camera 7 Zhejiang NeoDen Technology Co Ltd ...

Страница 35: ...8 2 Component Positions Setup 35 Zhejiang NeoDen Technology Co Ltd ...

Страница 44: ...11 Structure and maintenance instruction 11 1 Feeder Brief Introduction 44 Zhejiang NeoDen Technology Co Ltd ...