IMO-240 EN - Issue 7/2020

4

3.2 INSTALLING IN THE PIPELINE

WARNING:

THE VALVE SHOULD BE TIGHTENED BETWEEN

FLANGES USING GASKETS AND FASTENERS

COMPATIBLE WITH THE APPLICATION, AND IN

COMPLIANCE WITH APPLICABLE PIPING CODES

AND STANDARDS. CENTER THE VALVE AND FLANGE

GASKETS CAREFULLY BETWEEN FLANGES. DO NOT

ATTEMPT TO CORRECT PIPELINE MISALIGNMENT BY

MEANS OF FLANGE BOLTING!

The valve may be installed in any position and offers tight

shut-off in either flow direction. When in a horizontal line, it is not

recommended to install a valve with the stem on the underneath

side as debris in the pipeline may enter the body cavity and damage

the gland packing.

Refer to Section 4,

MAINTENANCE

for stem seal adjustment. If

there is seepage past the stem seal upon installation, it means

the valve may have been subject to wide temperature variations in

shipment. Leak-tight performance will be restored by a simple stem

seal adjustment described in the

MAINTENANCE

section.

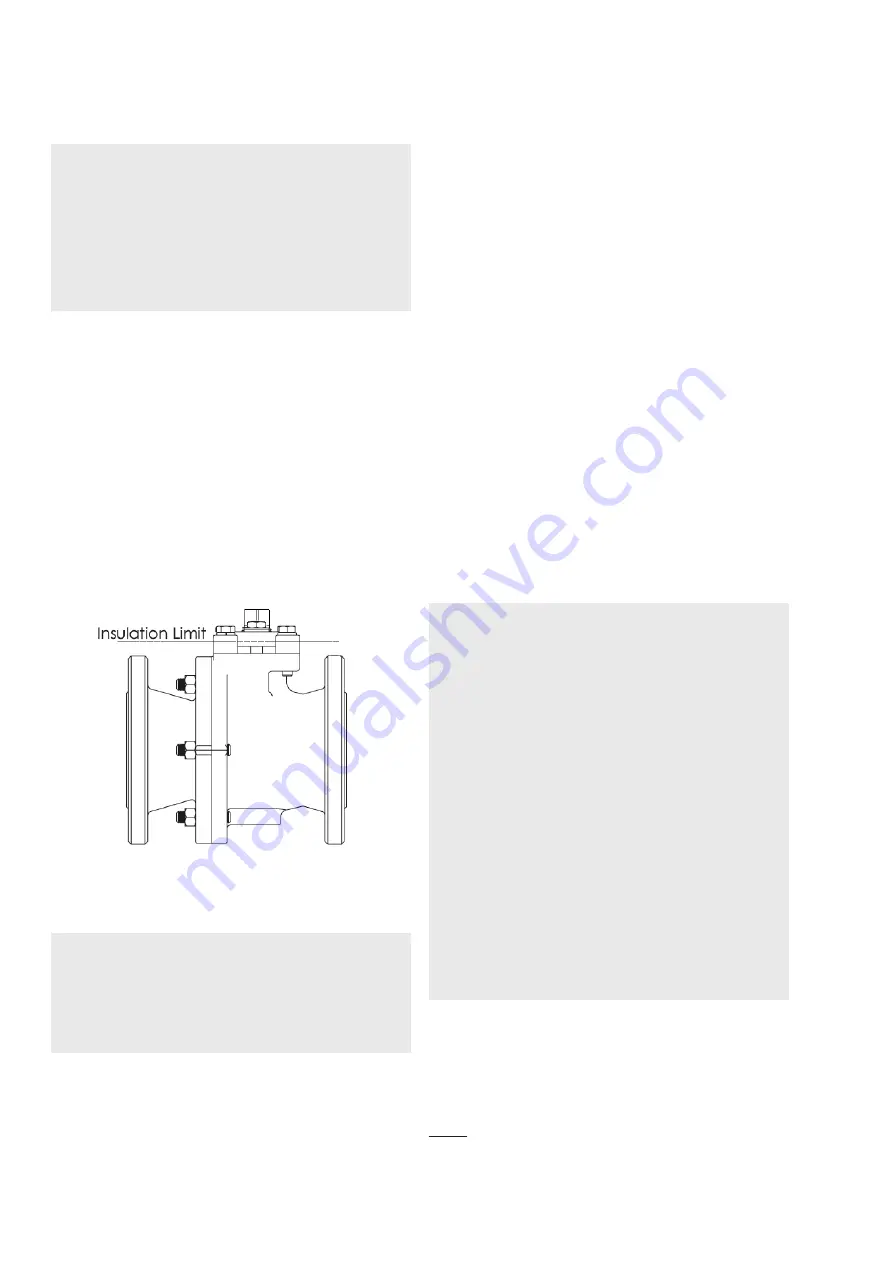

3.3 VALVE INSULATION

Easyflow by Neles™ ball valves do not require insulation. If desired,

the valve may be insulated; however, the insulation must not continue

above the upper level of the valve. See

Figure 2.

Figure 2.

Insulation of the valve

3.4 ACTUATOR

WARNING:

WHEN INSTALLING THE ACTUATOR ON THE

VALVE, MAKE SURE THAT THE VALVE ASSEMBLY

FUNCTIONS PROPERLY. INFORMATION ON ACTUATOR

INSTALLATION IS GIVEN IN SECTION 7 OR IN THE

SEPARATE ACTUATOR INSTRUCTIONS.

The actuator should be installed in a manner that allows plenty of

room for its removal.

The actuator must not touch the pipeline, tanks, walls, or other

equipment because vibration may interfere with its operation.

3.5 COMMISSIONING

Ensure that there is no dirt or foreign objects left inside the valve

or pipeline. Flush the pipeline carefully. Make sure that the valve is

fully open when flushing.

Ensure that all nuts, fittings, and cables are properly fastened.

If so equipped, check that the actuator positioner and/ or switch(s)

are correctly adjusted. Actuator adjustment is in Section 5. To

adjust any accompanying device(s) refer to the separate control

equipment instruction manuals.

4. MAINTENANCE

4.1 GENERAL

Although Easyflow by Neles™ valves are designed to work under

severe conditions, proper preventative maintenance can significantly

help to prevent unplanned downtime and reduce the total cost of

ownership. Neles recommends inspecting valves at least every five

(5) years. The inspection and maintenance frequency depend on

the actual application and process condition. Routine maintenance

consists of tightening the gland flange bolts (item 16 in

exploded

view

) periodically to compensate for stem seal wear.

Always loosen and tighten fasteners with the appropriate wrench to

avoid damaging the valve, handle, linkage, actuator, fittings or flats.

Overhaul maintenance consists of replacing seats and seals.

These parts may be obtained from Neles or an Authorized Neles

Distributor.

WARNING:

FOR YOUR SAFETY, IT IS IMPORTANT THE FOLLOWING

PRECAUTIONS BE TAKEN PRIOR TO REMOVAL OF

THE VALVE FROM THE PIPELINE OR BEFORE ANY

DISASSEMBLY:

1.

BE SURE YOU KNOW WHAT FLUID IS IN THE

PIPELINE. IF THERE IS ANY DOUBT, DOUBLE-

CHECK WITH THE PROPER SUPERVISOR.

2. WEAR ANY PERSONAL PROTECTIVE EQUIPMENT

(PROTECTIVE CLOTHING OR EQUIPMENT)

REQUIRED WHEN WORKING WITH THE FLUID

INVOLVED.

3.

DEPRESSURIZE THE PIPELINE AND CYCLE THE

VALVE AS FOLLOWS:

A. PLACE THE VALVE IN THE OPEN POSITION

AND DRAIN THE PIPELINE.

B. CYCLE THE VALVE TO RELIEVE RESIDUAL

PRESSURE IN THE BODY CAVITY BEFORE

REMOVAL FROM THE PIPELINE

C. AFTER REMOVAL AND BEFORE DISASSEMBLY,

CYCLE THE VALVE AGAIN SEVERAL TIMES.

4.2 ACTUATED VALVE

It is generally most convenient to detach the actuator and its auxiliary

devices before removing the valve from the pipeline. If the valve

package is small or if it is difficult to access, it may be more practical

to remove the entire assembly.

NOTE:

To ensure proper reassembly, observe the position of the

actuator and positioner/limit switch with respect to the valve before

detaching the actuator.

Содержание Easyflow J7 DN15

Страница 10: ...IMO 240 EN Issue 7 2020 10 ...

Страница 11: ...11 IMO 240 EN Issue 7 2020 ...