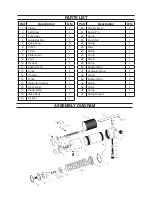

NOTE:

For best service you should incorporate an oiler, regulator, and

in-line filter

(none

of which are included) as shown in

Figure 1.

NOTE:

If you are

not

using an automatic oiler system as shown in

Figure 1,

add a few

drops of pneumatic tool oil (not included) to the airline connection. Add a few drops

after each hour of continual operation.

Prepare a 1/4” air connector (not included) by wrapping the threads with plumbers

tape before connecting to the Air Inlet (19) on the bottom of the Air Punch/Flange

Tool. Thread the Air Hose from your compressor to the Air Punch/Flange Tool at

the Air Inlet (19).

Set the air pressure on your compressor to 90 PSI. Do not exceed 90 PSI.

Frequently check the air connections to make sure they remain secure.

2.

3.

4.

OPERATION INSTRUCTIONS

PUNCHING

WARNING: Always wear heavy-duty leather gloves when handling sheet

metal.

Sharp edges can cause severe injury. Always wear ANSI-approved safety

goggles.

Pre-mark the desired location of each hole you wish to punch on the workpiece.

NOTE:

If the workpiece is to be both punched and

flanged,

flange

it

first,

then measure for

the hole placement. Flanging will change the dimensions of the workpiece.

Connect the Air Punch/Flange Tool to your air supply. Do not exceed 90 PSI.

Insert the edge of the workpiece between the Punch Die (3) and the Punch (6).

Make sure your marks are aligned with the Punch Die (3).

Squeeze the Throttle Lever (20) and the Punch (6) will pierce the workpiece.

Align the tool with the next mark on the workpiece and repeat step 5 until the job

is finished.

Disconnect the air supply.

WARNING: After disconnecting the Air Punch/Flange Tool from the air supply

there could still be enough air pressure to

fire

the Punch/Flange.

After making

sure the air supply is disconnected, ALWAYS

fire

the Punch/Flange repeatedly to

make sure all air is bled from the tool.

1.

2.

3.

4.

5.

6.

7.

8.