µ

PD75P308

30

6. RECOMMENDED SOLDERING CONDITIONS

It is recommended that

µ

PD75P308 be soldered under the following conditions.

For details on the recommended soldering conditions, refer to Information Document "Semiconductor

Devices Mounting Manual" (IEI-616).

The soldering methods and conditions are not listed here, consult NEC.

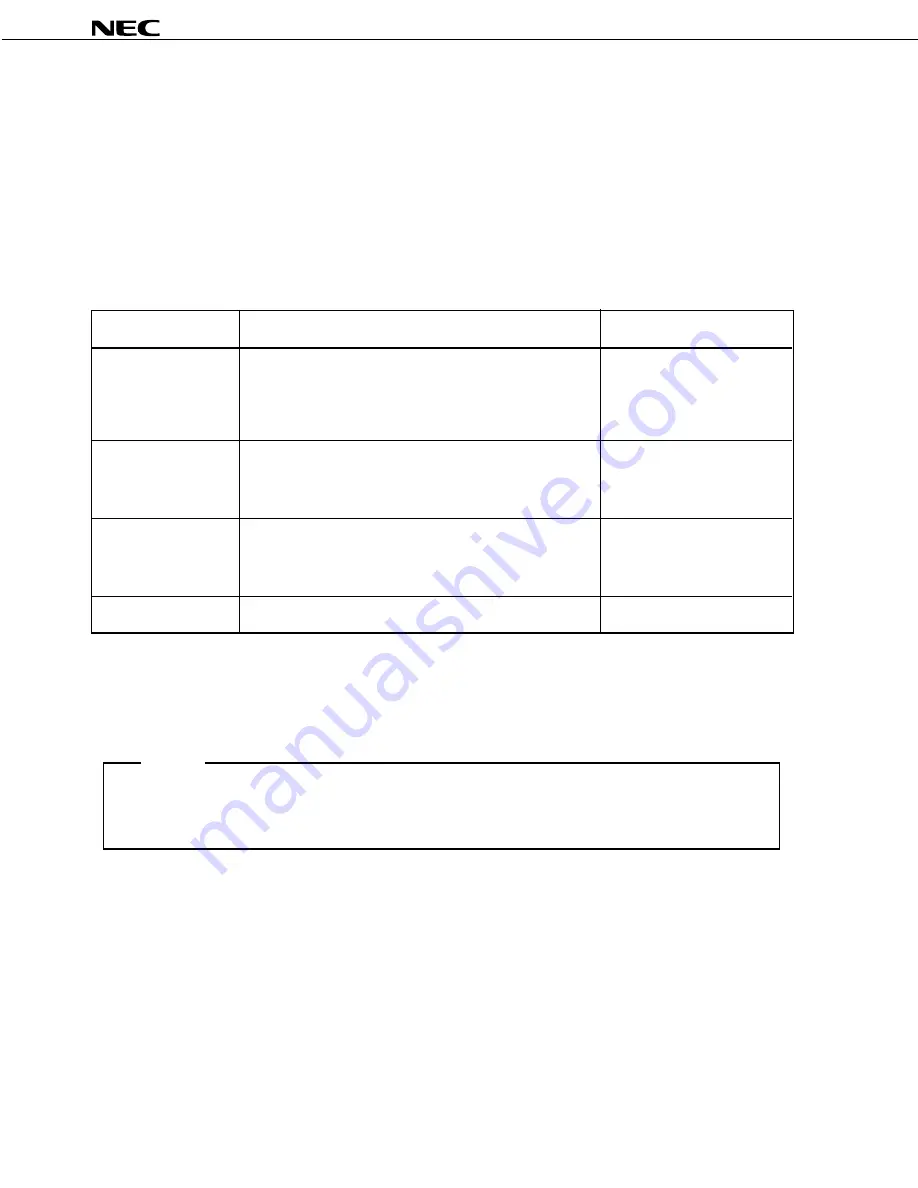

Table 6-1 Soldering Conditions

µ

PD75P308GF-3B9: 80-pin plastic QFP (14 x 20 mm)

Soldering Method

Soldering Conditions

Symbol for Recommended

Condition

Wave Soldering

Soldering bath temperature: 260

°

C max.,

WS60-162-1

time: 10 seconds max., number of times: 1,

pre-heating temperature: 120

°

C max. (package surface

temperature), maximum number of days: 2 days*,

(beyond this period, 16 hours of pre-baking is required

at 125

°

C).

Infrared Reflow

Package peak temperature: 230

°

C,

IR30-162-1

time: 30 seconds max. (210

°

C min.),

number of times: 1, maximum number of days: 2 days*

(beyond this period, 16 hours of pre-baking is required

at 125

°

C)

VPS

Package peak temperature: 215

°

C,

VP15-162-1

time: 40 seconds max. (200

°

C min.),

number of times: 1, maximum number of days: 2 days*

(beyond this period, 16 hours of pre-baking is required

at 125

°

C)

Pin Partial Heating

Pin temperature: 300

°

C max.,

—

time: 3 seconds max. (per side)

*:

Number of days after unpacking the dry pack. Storage conditions are 25

°

C and 65%RH max.

Caution: Do not use two or more soldering methods in combination (except the pin partial heating

method).

★

A model that can be soldered under the more stringent conditions (infrared reflow peak

temperature: 235

°

C, number of times: 2, and an extended number of days) is also available.

For details, consult NEC.

Notice

Содержание mPD75P308

Страница 32: ...µPD75P308 32 APPENDIX B RELATED DOCUMENTS ...