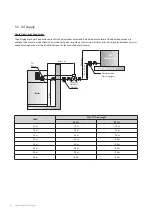

28 Connecting the Oil Supply

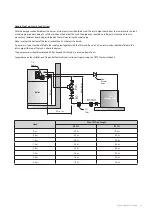

5.1 Essential Elements in the Oil Supply

This appliance is suitable for Kerosene (Class C2) and Light-oil.

No other fuel may be used.

Fuel Storage Tank

The tank should be positioned in accordance with the

recommendations given in BS 5410:1:1997, which gives details

for filling, maintenance and protection from fire.

A steel tank may be used and must be constructed to BS

799:5:1987 and OFS T200.

CAUTION

Ɣ

A galvanised tank must not be used.

Ɣ

A plastic tank may be used and must comply with OFS

T100.

Note

Plastic tanks should be adequately and uniformly

supported on a smooth level surface, across their

entire base area, that is, the area in contact with the

ground.

Regulations & Standards

In England and Wales, installations in singe family dwellings

have to comply with building Regulations Part J. This requires

compliance with BS 5410 Part 1:2014. All tanks either deemed to

be at risk or with a capacity of more than 2500 litres are required

to be bunded.

For installation in Scotland, Building Standard Part F applies. This

requires compliance with BS 5410 Part 1:2014 and BS 5410 Part

2:2013. All tanks either deemed to be at risk or with a capacity of

more than 2500 litres are required to be bunded.

Those externally installed tanks with a capacity of less than 2500

litres will require a bund if located not more than 50 metres from

a spring or bore hole, 10 metres from controlled waters and,

additionally, where it may constitute a hazard.

The above risks and hazards are described in OFTEC book 3.

In Northern Ireland, the Building Regulations do not currently

cover the installation of oil storage tanks.

In the Republic of Ireland the requirements of BS 5410 Part

1:2014 and BS 5410 Part 2:2013 are required to be in compliance

with Building Regulations Part J.

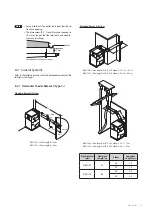

Fuel Pipes

Fuel supply pipes should be of copper tubing with an external

diameter of at least 10 mm.

Galvanised pipes may not be used.

All pipe connections should preferably use flared fittings.

Soldered connections must not be used on oil pipes.

CAUTION

Flexible hoses must not be used outside the boiler.

Fire Valve

A fire valve is an essential part of the oil supply system. It should

be capable of cutting off the flow of oil outside the building in

the event of a fire starting within the boiler. The valve should

be located just outside the building at the point where the

oil supply line enters. It must be activated by a remote sensor

located over the burner, but in a position clear of any direct

radiation or excessive heat.

Note

Ɣ

Fire valves should comply with OFTEC Standards

OFS E101.

Ɣ

Fitting of fire valves should comply with BS5410

Part 1:2014 and OFTEC book 3.

Oil Strainer & Water Separator

Fit an oil strainer and water separator to the oil supply pipe, near

the oil storage tank.

Fit an additional oil filter (74μm max filtration size) close to the

boiler, but not inside the boiler.

Install a manual shut-off valve. It should be fitted before

installing the filter, to allow the filter to be serviced. Install the

valve as close to the oil storage tank as possible.

CAUTION

Contaminants can lead to system damage. The oil line must

be flushed prior to commissioning.

5. Connecting the Oil Supply

Содержание LCB700-21LC

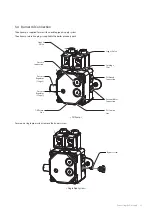

Страница 78: ...78 Appendices 13 2 2 Burner Cover Flame Tube...

Страница 80: ...80 Appendices Oil Pump Coupling Orifice Swirl Plate Oil Pump Motor Oil Pump Intake Pipe Flame Holder Assembly...

Страница 86: ...86 Appendices 13 2 5 DHW Parts 20 11 10 13 14 12 19 23 22 27 21 26 25 28 24 16 17 18 6 7 8 9 15 4 5 2 3 1...

Страница 92: ...Memo...

Страница 93: ...Memo...

Страница 94: ...Memo...

Страница 95: ......