The impact of noise can cause damage to

hearing.

In operation

Vibration emission value a

h

= 6,888 m/s

2

K uncertainty = 1,5 m/s

2

Reduce noise generation and vibration to a

minimum!

•

Use only equipment that is in perfect condition.

•

Maintain and clean the equipment regularly.

•

Adopt your way of working to the equipment

. •

Do not overload the equipment.

• H

ave the equipment checked if necessary.

•

Wear gloves.

5. Assembly

Important!

Do not start the chainsaw until it has been fully

assembled and the chain tension has been

adjusted.

Always wear protective gloves when working

on the chainsaw to protect yourself against

injury.

5.1 Joining the gear unit to the drive rod

mechanism (Fig. 4-6)

Tools required: Allen keys size 4mm/5mm

(supplied) Push the gear unit (Item 3b) and the

drive rod mechanism (Item 4) into each other.

Center both by turning the screw (Item K).

Important! Make sure that the screw (Item K)

is turned exactly into the guide hole (Item F).

Otherwise there is a risk of the upper part of the

rod mechanism being damaged. To join the two

subassemblies securely together, tighten the

screw (Item I). To take apart, proceed in reverse

order.

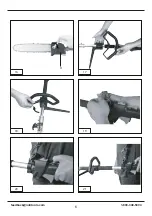

5.2 Joining the drive rod mechanism to the

connecting piece (Fig. 7-10)

Open the handle screw (Item G) and push the

drive rod mechanism (Item 4) into the connecting

piece (Item 5). Make sure that the centering lever

(Item R) latches in the guide hole (It

em H). Close

the guard cap (Item N) and tighten the handle

screw. To take apart, undo the handle screw and

open the guard cap. Press the centering lever and

simultaneously pull the drive rod mechanism out

of the connecting piece.

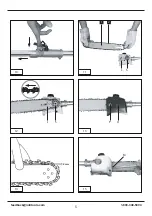

5.3 Fitting the cutter bar and the chain

(Fig. 11-16)

Tools required: Allen key size 5mm

Remove the chain wheel cover (Fig.13/ Item O)

by undoing the fastening screw (Item P). Lay the

chain (Item 2) as shown into the groove which

runs around the cutter bar (Item 1). Note the

alignment of the chain teeth (Fig. 12). Insert the

cutter bar as shown in Fig. 12 into the mount at

the gear unit. Place the chain round the chain

wheel (Item S). Make sure that the teeth of

the chain engage securely in the chain wheel.

The cutter bar must be hooked into the chain

tensioning bolt (Item L).

Fit the chain wheel cover.

Important! Do not fully tighten the fastening

screw until after you have adjusted the chain

tension (see section 5.4).

5.4 Tensioning the chain (Fig. 14-16)

Important!

Always pull out the spark boot plug

before performing any checks or adjustments.

Undo the fastening screw (Item P) of the chain

wheel cover by a few turns (Fig. 13). Adjust the

chain tension with the chain tensioning screw

(Fig. 15/Item M). Turning the screw clockwise

increases the chain tension, turning it

counterclockwise decreases the chain tension.

The chain is correctly tensioned if it can be raised

by around 2 mm in the middle of the cutter bar

(Fig. 14).

(Fig. 16).

Important! All the chain links must lie properly in

the guide groove of the cutter bar.

Notes on tensioning the chain:

The chain must be properly tensioned to ensure

safe operation. When the saw chain can be raised

by around 2 mm in the middle of the cutter bar,

you know that the chain tension is ideal. During

cutting, the temperature of the chain rises and its

1-800-348-5004

11

Содержание BlueMAX 53542

Страница 4: ...4 5 4 3a 3b 25 4 6 8 5 K I N G R G H 7 9 1 800 348 5004 feedback natitools com 4...

Страница 5: ...2 mm 10 12 14 11 13 15 1 2 L S L P S O M 1 800 348 5004 feedback natitools com 5...

Страница 6: ...16 18 20 17 19 21 O 1 800 348 5004 feedback natitools com 6...

Страница 7: ...23 25 27 24 26 a b T 22 1 800 348 5004 feedback natitools com 7...

Страница 8: ...29 28 30 13 1 800 348 5004 feedback natitools com 8...