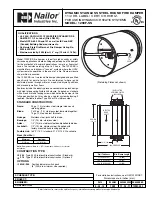

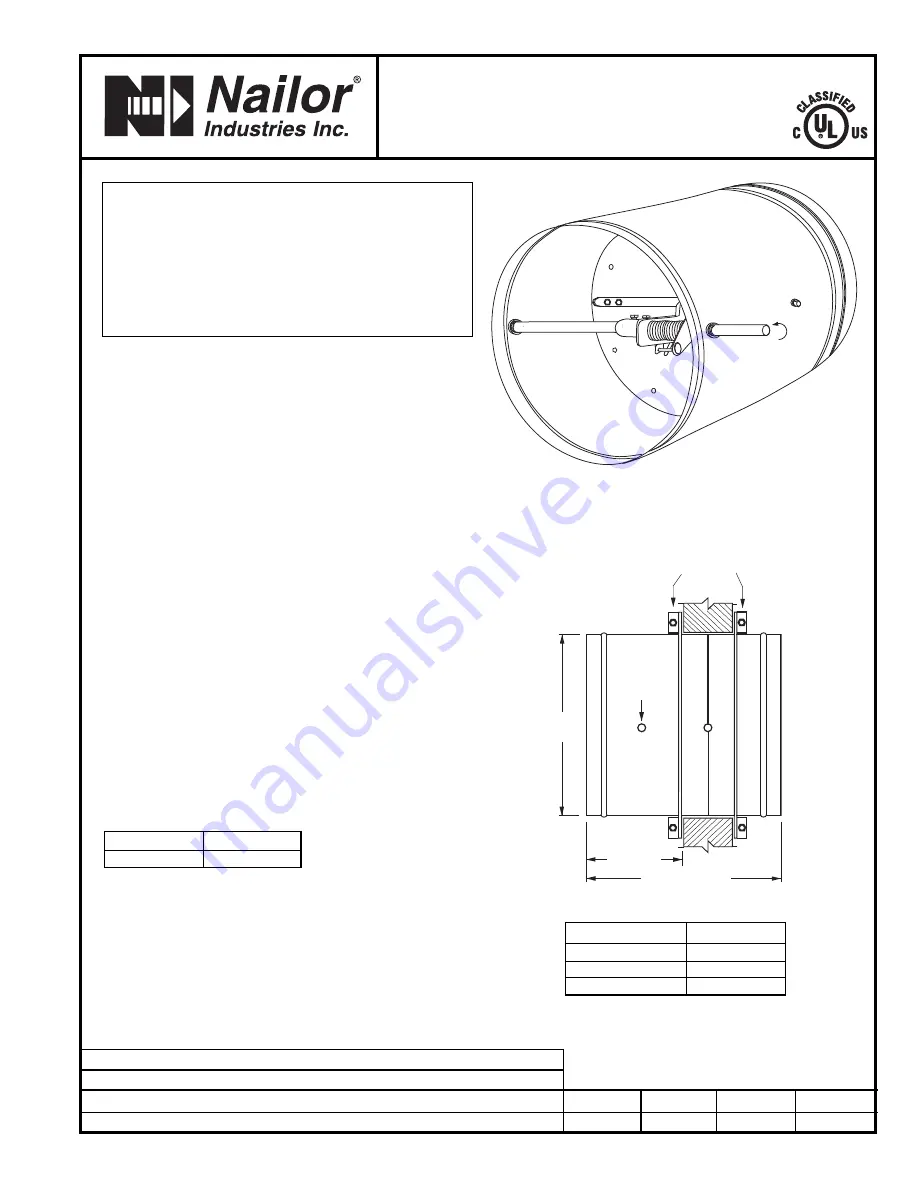

5 3/4" (146)

16" (406) STANDARD

NOM. DIA.

- 1/8" (3)

ACTUATOR

DRIVE

SHAFT

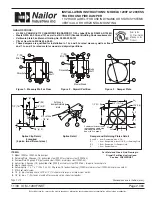

INSTALLATION

RETAINING PLATES

INCLUDED

Model 1290F-SS fire damper is ideal for high humidity or mildly

corrosive applications where building codes require a fire damper

for the protection of ductwork penetrations in walls or floors that

have a fire resistance rating of up to 2 hours. The 1290F-SS is

classified for use in dynamic "fans on" systems where the HVAC

system remains operative in the event of a fire. Damper closure

under airflow is assured.

The 1290F-SS is a true round fire damper designed and qualified

specifically for point-of-origin fire containment where round

ductwork passes through metal or wood stud drywall partitions

and masonary walls or floors.

Features include the industry proven over-center knee lock design

with high torque spring/fusible link closure. Supplied as standard

with a crank arm and locking screw which holds the damper in the

fully open position, but may also be used for system balancing if

required. Available in either Type 304 or 316 stainless steel.

STANDARD CONSTRUCTION:

Frame:

20 ga. (1.0) stainless steel integral sleeve and

retaining plates.

Blade:

2 x 20 ga. (1.0) stainless steel laminated together.

14 ga. (2.0) equivalent thickness.

Linkage:

Stainless steel; jackshaft to blade.

Bearings:

1/ 2" (13) dia. stainless steel.

Axles:

1/2" (13) dia. stainless steel double bolted to blades.

Jackshaft:

1/2" (13) dia. stainless steel. Supplied with

factory mounted hand locking quadrant.

Fusible Link:

165°F (74°C) standard. 212°F (100°C) available.

Sizes (Duct Dia.):

Note:

Dampers available in 1" (25) increments. Vertical or horizontal

installation.

CONSTRUCTION TYPE:

❑

304

Type 304 Stainless Steel construction (Standard)

❑

316

Type 316 Stainless Steel construction (Optional)

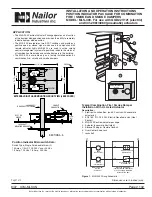

OPTIONS:

❑

MLS-300

Position indicator switch pack

(8" (203) dia. minimum size required)

QUALIFICATIONS:

• UL 555 & CAN/ULC-S112 CLASSIFIED DYNAMIC FIRE

DAMPER 1 1/2 hr. Label (File # R9492).

• Meets NFPA 80, 90A and 101 as well as IBC and NBC

(Canada) Building Code requirements.

• California State Fire Marshal: Fire Damper Listing No.

3225-0935:0101.

• Maximum velocity: 2000 fpm @ 4" w.g. (10 m/s @ 1 kPa).

Minimum

Maximum

6" (152) dia.

24" (610) dia.

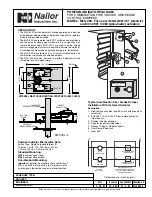

Wall Thickness

Min. Sleeve Length

4 to 8 (102 to 203)

16 (406)

10 to 12 (254 to 305)

20 (508)

14 to 16 (356 to 406)

24 (610)

SCHEDULE TYPE:

PROJECT:

ENGINEER:

CONTRACTOR:

DATE

B SERIES

SUPERSEDES DRAWING NO.

4 - 28 - 14

1200

11 - 28 - 11

1290F-SS-1

DYNAMIC STAINLESS STEEL ROUND FIRE DAMPER

1 1/2 HR. LABEL • VERT. OR HORIZ.

FOR USE IN DYNAMIC OR STATIC SYSTEMS

MODEL: 1290F-SS

Nailor Industries Inc. reserves the right to change any information concerning product or pricing without notice.

For installation instructions, see IOM-1290FINST.

Dimensions are in inches (mm).

CCW

TO

OPEN

(Retaining Plates not shown)