Page-20

9. Safety measures against transport

The following describes precautions for transporting the robot. Fully understand the precautions for

safe transport work.

WARNING

The robot must be transported by personnel who have licenses required for slinging

work, crane operation, forklift truck operation, and others. The weight of the robot and

controller is listed in the Operating Manual and the Maintenance Manual. Check for the

weight, and then handle them according to procedures suitable for the weight.

WARNING

To lift the robot or the controller, follow the procedures specified in the Maintenance

Manual. Following any procedures other than those specified will cause the robot to

topple over or drop during transport, thus resulting in accidents.

WARNING

During transport or installation work of the robot, pay utmost care not to cause damage

to wirings. Furthermore, after installing the robot, take protective measures such as using

protective guards so that the wirings will not be damaged by workers or other persons, or

forklift trucks or else.

WARNING

Gas in balancer must be released when robot is transported by air.

Gas in balancer must be charged before using robot, so customer needs to prepare the

nitrogen gas and charging unit. Please contact to NACHI-FUJIKOSHI office to order the

charging unit. Charging procedure is written in manipulator maintenance manual.

To transport the robot, make it a rule to use a crane.

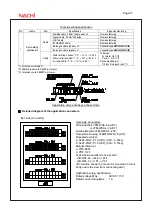

At first, put the robot into the configuration shown in figure below and mount the four M20 hanger bolts

to the swivel base. Then, be sure to lift the robot using four hanging wires. For this purpose, it is

recommended to use hanging wires of 3 m in length and protect areas that contact the robot, using

rubber hoses to cover the wire ropes. For the areas to be covered with the rubber hoses refer to figure

below.

SRA220H-01

SRA220HV-01

Axis 1

0

°

0

°

Axis 2

+145

°

+134

°

Axis 3

-74

°

-74

°

Axis 4

-90

°

-90

°

Axis 5

0

°

0

°

Axis 6

+90

°

+90

°

L 1766mm 1709mm

L1 892mm 756mm

L2 874mm 953mm

H 1681mm 1839mm

Содержание SRA220H Series

Страница 1: ...Standard specifications SRA220H 01 FD11 SRA220HV 01 FD11 7th edition 1707 SSRAEN 064 007 001 ...

Страница 5: ...Page 3 3 Robot dimensions and working envelope SRA220H 01 ...

Страница 6: ...Page 4 SRA220HV 01 ...

Страница 11: ...Page 9 SRA220HV 01 Robot type ...

Страница 20: ...Page 18 8 2 Spot welding specification 2 Connecting diagram Standard ...

Страница 25: ......