4

7) Kindly note that MYR-0206/0309/0412/0618/0412F/0618F/0825 will be enclosed with the torque fixing

ring. The torque fixing ring can protect the operator and avoid getting hurt by the threads on the

screwdriver. And it can fix the torque and prevent the torque to be adjusted. In order to prevent getting

hurt, kindly check if the torque fixing ring is fixed when using the screwdriver and adjusting the torque.

8) When operating a tool for over 70 kgf.cm application, please make sure to use it with an auxiliary arm to

avoid the operator's injury or unexcepted tool performance.

If a user doesn’t mount the tool on an auxiliary arm, he/she needs to take the responsibility for any injury or

product quality issue caused.

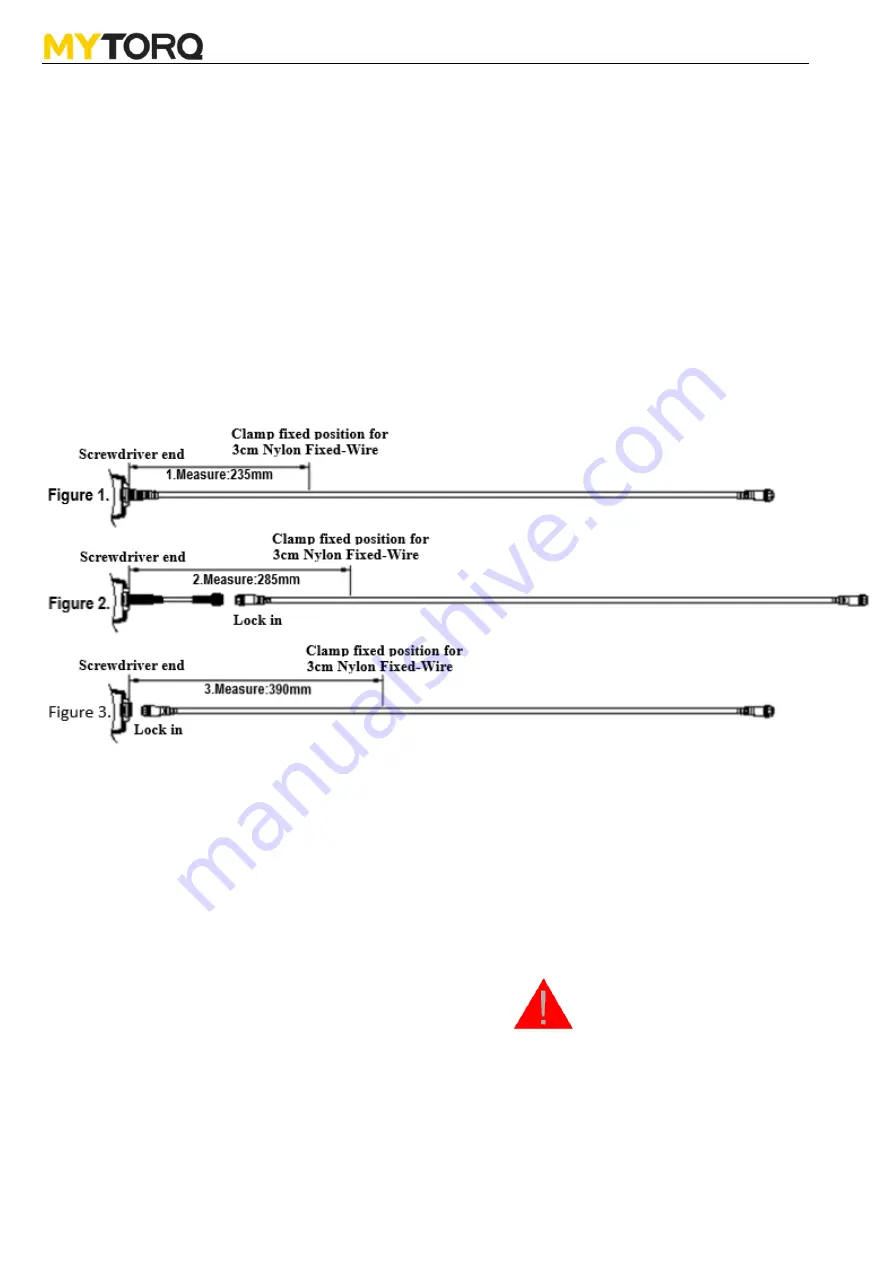

9) Clamp fixed position for 3cm Nylon Fixed-Wire

The clamp fixed position for 3cm Nylon Fixed-Wire is at 235mm start count from the top of the screwdriver flat

surface (for direct cable), as shown in Figure 1.

The clamp fixed position for 3cm Nylon Fixed-Wire is at 285mm start count from the top of the screwdriver flat

surface( for 15 cm tail cable), as shown in Figure 2.

The clamp fixed position for 3cm Nylon Fixed-Wire is at 390mm start count from the top of the screwdriver flat

surface (for Iron ring socket type), as shown in Figure 3.

WARNING

!

DO NOT OPERATE THIS TOOL WITHOUT

PROTECTIVE EARTH CONNECTED