29

Subject to modifications

•

19, rue de Rennes

•

BP 83221 • F - 35690 ACIGNÉ

18. MAINTENANCE

Drain the tractor’s hydraulic circuit regularly and change the filters following

the manufacturer’s recommendation.

Polluted oil stops lubricating, and wears all the hydraulic components

(pumps, control valves, rams). Even clear oil can be overused.

Maintenance operations must be performed by competent persons, authorised by the dealer

. If this is not the case,

these operations shall fall under the sole responsibility of the person carrying out the work.

It is mandatory to wear PPE (Personal Protective Equipment) during all maintenance operations. Please refer

to the "PPE table". See Chapter "SAFETY RULES".

For loader maintenance operations, never work on mechanical parts under stress or on a pressurised circuit,

hydraulic part, or electrical circuit that is switched on.

For tractor maintenance operations, it is strongly recommended to unhitch the loader. Unhitching is a simple quick

operation that provides the best guarantees of safety and efficiency for tractor maintenance.

For any work with the lifted loader, the loader must be locked in position:

Unlocking of the MACH System or closure of the supply valve of the lifting rams for a loader without MACH System.

(See the "LOADER UNHITCHING" chapter).

When using a pressure washer, avoid spraying water on electric components.

Clean the implement and the front of the loader after every use.

Slurry acid, fertiliser and silage can damage paint, steel and pivot

points.

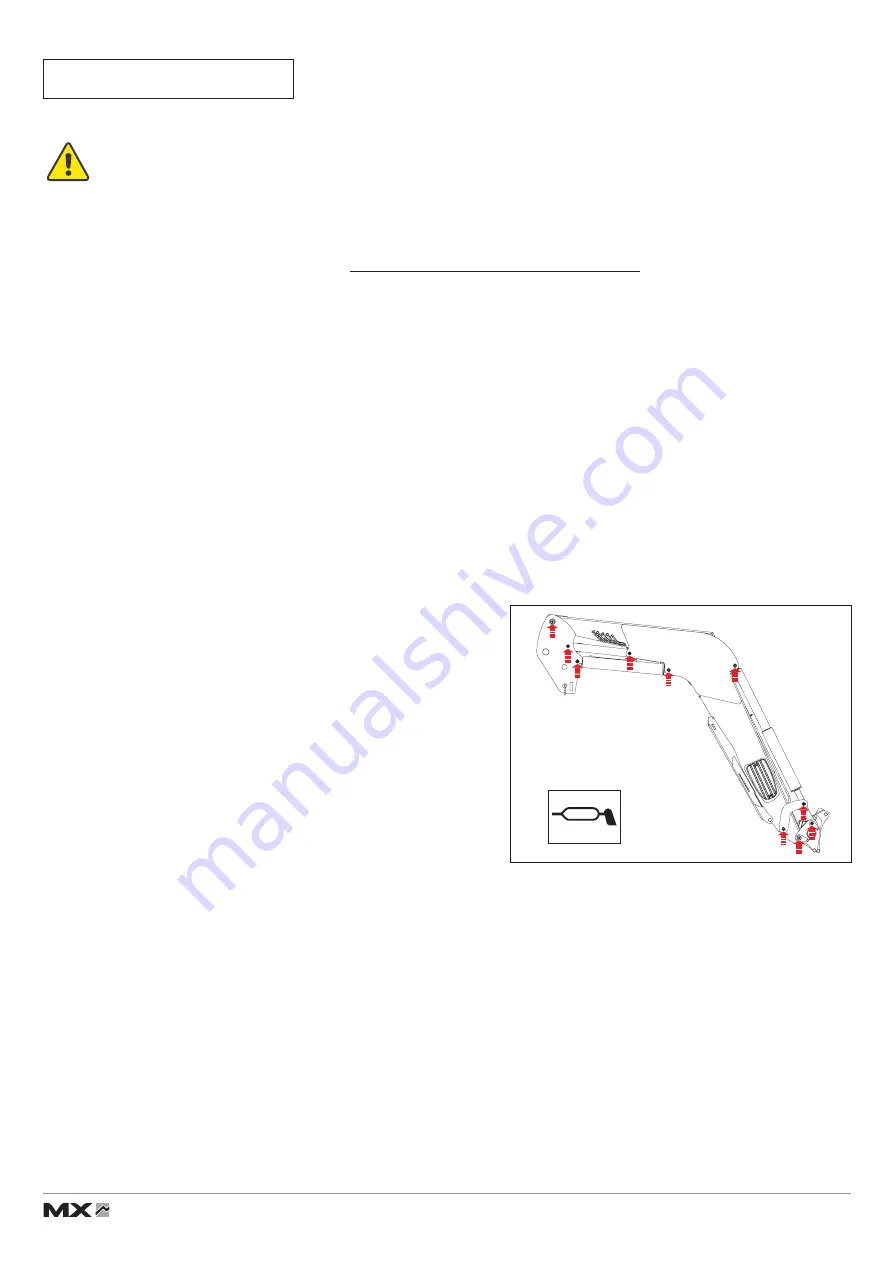

Lubricate every 10 hours and after each wash (

water drives

grease out

) and particularly after washing with a pressure washer.

See lubrication points opposite.

Every month, or more often with heavy use, check:

—

The condition of the loader’s pivot points. As required, replace wear bushes and/or the pins.

Wear bushes must be replaced if they are less than 1 mm thick.

—

The level of the tractor’s hydraulic oil and the sealing of the hydraulic circuit. If you find any internal or external leaks

on hydraulic components (rams, pipes, connectors, Mach, couplings, etc.), contact your dealer.

—

The condition of the hoses: replace them if any cracks or oil seepages appear.

—

The correct operation of the monolever (cables, play, locking, etc.).

—

The condition of the electric cabling. Contact your dealer if any connectors or cables are damaged.

—

The mechanical condition (any cracks, distortion, end stop matting, play, parking stands, etc.).

Contact your dealer if there is any abnormal wear.

—

Scrapping: please contact your dealer or a company specialising in materials recycling.