ENGLISH

17

F–041004L

NOTE: To assemble the auger housing

(22) to the motor box (23), have someone

hold the auger clutch lever in the EN-

GAGED position. This will move the idler

arm and pulley (3) enough to allow the

auger drive pulley (10) to move back into

position.

11. Assemble the

auger housing (22)

to the

motor box (23)

with the four

bolts (21)

that

were removed in step 8. Tighten the bottom

two

bolts (24).

12.Install the

auger drive belt (4)

onto the

en-

gine pulley (11)

.

13.Slip the

auger drive belt (4)

under the

idler

pulley (3)

.

14.Adjust the

auger drive belt (4)

. See “How To

Adjust The Auger Drive Belt” in the Mainte-

nance section.

15.Adjust the

belt guide (9)

. See “How To Ad-

just The Belt Guide” in the Maintenance sec-

tion.

16.

(Figure 13)

Install the

belt cover (1)

. Tighten

screw (2)

.

17.Check the adjustment of the cables. See

“How To Check And Adjust The Cables” in

the Maintenance section.

18.

(Figure 17)

Install the

bottom panel (2)

.

19.Tighten the

bolts (3)

on each side of the

bot-

tom panel (2)

.

20.Connect the spark plug wire.

How To Remove the Traction Drive Belt

If the snow thrower will not move forward, check

the traction drive belt for wear or damage. If the

traction drive belt is worn or damaged, replace

the belt as follows.

1. Disconnect the spark plug wire.

2. Remove the auger drive belt. See “How To

Remove The Auger Drive Belt” in the Mainte-

nance section.

3.

(Figure 14)

Remove the

e–ring (17)

from

one end of the

swing plate axle rod (18).

Remove the

swing plate axle rod (18)

to

allow the the swing plate to pivot forward.

4. Remove the

traction drive spring (16).

5. Remove the old

traction drive belt (13)

from

the

traction drive pulley (14)

and from the

engine pulley (15)

. Replace the

traction

drive belt (13)

with an original factory re-

placement belt available from an authorized

service center.

6. Install the new

traction drive belt (13)

onto

the

traction drive pulley (14)

and onto

en-

gine pulley (15)

.

7. Make sure the

traction drive idler pulley

(12)

is properly aligned with the

traction

drive belt (13)

.

8. Attach the

traction drive spring (16).

9. Install the

swing plate axle rod (18)

and se-

cure with the

e–ring (17)

removed earlier

.

10.

(Figure 26)

The bottom of the

swing plate

(20)

must be positioned between the

align-

ment tabs (19).

Make sure the

swing plate

(20)

is properly secured.

NOTE: If the drive will not engage after

the traction drive belt has been replaced,

then check to make sure that the swing

plate is positioned between the alignment

tabs (19).

11.

(Figure 14)

Install and adjust the

auger

drive belt (4)

. See “How To Remove The

Auger Drive Belt” in the Maintenance section.

12.Adjust the

belt guide (9)

. See “How To Ad-

just The Belt Guide” in the Maintenance sec-

tion.

13.

(Figure 17)

Install the

bottom panel (2)

.

14.Tighten the

bolts (3)

on each side of the

bot-

tom panel (2)

.

15.

(Figure 13)

Install the

belt cover (1)

. Tighten

screw (2)

.

16.Check the adjustment of the cables. See

“How To Check And Adjust The Cables” in

the Maintenance section.

17.Connect the spark plug wire.

How To Adjust The Belt Guide

1. Disconnect spark plug wire.

2.

(Figure 13)

Remove

screw (2)

. Remove the

belt cover (1)

.

3.

(Figure 2)

Engage the

auger drive lever (5)

.

4.

(Figure 18)

Measure the distance between

the

belt guide (2)

and

auger drive belt (3)

.

The

correct distance (4)

is 1/8 inch (3.175

mm).

5. If an adjustment is necessary, loosen the

mounting bolt for the

belt guide (2)

. Move

the

belt guide (2)

to the

correct position

(4)

. Tighten the mounting bolt for the

belt

guide (2)

.

6.

(Figure 13)

Install the

belt cover (1)

. Tighten

screw (2)

.

7. Connect the spark plug wire.

How To Adjust Or Replace The Friction

Wheel

How To Check The Friction Wheel

If the snow thrower will not move forward, check

the traction drive belt, the traction drive cable or

the friction wheel. If the friction wheel is worn or

damaged, it must be replaced. See

“How To

Replace the Friction Wheel” in this section. If the

friction wheel is not worn or damaged, check as

follows.

1.

(Figure 2)

Remove the gas from the gas

tank. Stand the snow thrower up on the front

end of the

auger housing (4)

.

WARNING: Drain the gasoline out-

doors, away from fire or flame.

2. Disconnect the spark plug wire.

3.

(Figure 17)

Loosen the

bolts (3)

on each

side of the

bottom panel (2)

.

4. Remove the

bottom panel (2)

.

5.

(Figure 2)

Position the

shift speed lever (6)

in the lowest forward speed.

6.

(Figure 19)

Note the position of the

friction

wheel (4).

The correct distance

“A”

from the

right side of the

friction wheel (4)

to the out-

side of the motorbox is as follows:

Tire Size

Distance “A”

12 and 13 inch

4-1/8” (10.5 cm.)

16 inch

4-5/16” (10.95 cm.)

If the

friction wheel (4)

is not in the correct

position, adjust as follows.

How To Adjust The Friction Wheel

1.

(Figure 2)

Position the

shift speed lever (6)

in the lowest forward speed.

2.

(Figure 20)

Loosen the

bolts (1)

on the

speed control rod (8)

.

3.

(Figure 19)

Move the

friction wheel (4)

to

the correct position.

4.

(Figure 20)

Tighten the

bolts (1)

on the

speed control rod (8)

.

5.

(Figure 17)

Install the

bottom panel (2)

.

6. Tighten the

bolts (3)

on each side of the

bot-

tom panel (2)

.

How To Replace The Friction Wheel

If the friction wheel is worn or damaged, the

snow thrower will not move forward. The friction

wheel must be replaced as follows.

1.

(Figure 2)

Remove the gas from the gas

tank. Stand the snow thrower up on the front

end of the

auger housing (4)

.

WARNING: Drain the gasoline out-

doors, away from fire or flame.

2. Disconnect the spark plug wire.

3.

(Figure 24)

Remove the fasteners that se-

cure the left

wheel (10).

Remove the

left

wheel (10)

from the

axle (11).

4. Loosen the

bolts (3)

on each side of the

bot-

tom panel (2)

.

5. Remove the

bottom panel (2)

.

6.

(Figure 25)

Remove the fasteners that se-

cure the

drive sprocket (12)

to the

axle (11).

7. Remove the right wheel,

axle (11),

and

drive

sprocket (12).

8.

(Figure 26)

Remove the four

bolts (16)

that

hold the

bearings (7)

on each side of the

hex shaft (8)

.

9.

(Figure 27)

Remove the

hex shaft (8)

and

bearings (7).

NOTE: Take special note of the position of

the washers (17) .

10.

(Figure 21)

Remove the three

fasteners (4)

that hold the

friction wheel (5)

to the

hub

(6).

11.

(Figure 21)

Remove the

friction wheel (5)

from the

hub (6)

. Slip the

friction wheel (5)

off the

hex shaft (8).

12.Assemble the new

friction wheel (5)

onto

hub (6)

with the fasteners removed earlier.

13.

(Figure 27)

Install the

hex shaft (8)

and

bearings (7)

with the four bolts removed ear-

lier

.

Make sure the washers (17) are properly

installed in the original position. Also,

make sure the two washers (13) are prop-

erly aligned with the actuator arms (14).

14.Make sure the

hex shaft (8)

turns freely.

15.

(Figure 25)

Install the right wheel,

axle (11),

and

drive sprocket (12)

with the fasteners

removed earlier. Install the

chain (15)

onto

the

drive sprocket (12).

16.Check the adjustment of the friction wheel.

See “How To Adjust The Friction Wheel” in

this section.

17.Make sure the friction wheel and the disc

drive plate are free from grease or oil.

18.

(Figure 17)

Install the

bottom panel (2)

.

19.Tighten the

bolts (3)

on each side of the

bot-

tom panel (2)

.

20.

(Figure 24)

Install the

left wheel (10)

to the

axle (11)

with the fasteners removed earlier.

21.Connect the spark plug wire.

How To Replace the Auger Shear Bolt

The augers are secured to the auger shaft with

special shear bolts. These shear bolts are de-

signed to break and protect the machine if an

object becomes lodged in the auger housing.

Do not use a harder bolt as the protection pro-

vided by the shear bolt will be lost.

Содержание 624808x4E

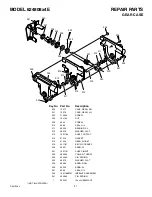

Страница 4: ...4 F 041004L 1 1 2 2 7 8 1 1 2 3 9 1 1 6 5 5 1 3 7 1 A 10 11 6 2 1 3 1 4 12 6 5 7 8 ...

Страница 5: ...5 F 041004L 1 2 10 11 14 16 13 15 9 4 12 3 13 17 18 13 14 21 15 24 23 22 16 4 5 17 5 6 8 3 2 3 ...

Страница 6: ...6 F 041004L 18 2 3 4 A 19 20 1 8 9 4 5 6 8 4 21 22 2 3 4 3 4 5 6 23 ...

Страница 7: ...7 F 041004L 24 11 3 3 2 10 11 12 15 25 11 7 16 16 19 20 8 7 14 13 13 7 26 27 17 17 ...

Страница 8: ...8 F 041004L 28 2 3943 2 9524 2 73826 ...

Страница 45: ...45 F 041004L ...

Страница 46: ...46 F 041004L ...

Страница 47: ...47 F 041004L ...