The gas tightness test procedure is as follows:

1. Once the piping system is completed and the indoor,

MS box and outdoor units have been connected,

vacuum the piping to -0.1 MPa.

2. Charge the indoor piping with nitrogen at 0.3 MPa

through the needle valves on the liquid, high pressure

and low pressure gas stop valves and leave for at least 3

minutes (do not open the liquid or gas stop valves).

Observe the pressure gauge to check for large leakages.

If there is a large leakage, the pressure gauge will drop

quickly.

3. If there are no large leakages, charge the piping with

nitrogen at 1.5 MPa and leave for at least 3 minutes.

Observe the pressure gauge to check for small

leakages. If there is a small leakage, the pressure gauge

will drop distinctly.

4. If there are no small leakages, charge the piping with

nitrogen at 4.0 MPa and leave for at least 24 hours to

check for micro leakages. Micro leakages are difficult to

detect. To check for micro leakages, allow for any

change in ambient temperature over the test period by

adjusting the reference pressure by 0.01 MPa per 1°C of

temperature difference. Adjusted reference pressure =

pressure at pressuri (temperature at observation

- temperature at pressurization) x 0.01 MPa. Compare

the observed pressure with the adjusted reference

pressure. If they are the same, the piping has passed the

gas tightness test. If the observed pressure is lower than

the adjusted reference pressure, the piping has a micro

leakage.

5. If the leakage is detected, refer to following part “Leak

detection”. Once the leak has been found and fixed, the

gas tightness test should be repeated.

6. If not continuing straight to vacuum drying once the

gas tightness test is complete, reduce the system

pressure to 0.5 - 0.8 MPa and leave the system

pressurized until ready to carry out the vacuum drying

procedure.

Vacuum drying should be performed in order to remove

moisture and non-condensable gases from the system.

Removing moisture prevents ice formation and

oxidization of copper piping or other internal

components. The presence of ice particles in the system

would cause abnormal operation, whilst particles of

oxidized copper can cause compressor damage. The

presence of non-condensable gases in the system would

lead to pressure fluctuations and poor heat exchange

performance.

Vacuum drying also provides additional leak detection

(in addition to the gastightness test).

During vacuum drying, a vacuum pump is used to lower

the pressure in the piping to the extent that any moisture

present evaporates. At 5 mm Hg (755 mm Hg below

typical atmospheric pressure) the boiling point of water is

0°C. Therefore a vacuum pump capable of maintaining a

pressure of -756 mm Hg or lower should be used. Using

####\$+#

a precision level of 0.02 mm Hg is recommended. The

vacuum drying procedure is as follows:

1. Connect the vacuum pump through a manifold with a

pressure gauge to the service port of all stop valves.

2. Start the vacuum pump and then open the manifold

valves to start vacuuming the system.

3. After 30 minutes, close the manifold valves.

4. After a further 5 to 10 minutes check the pressure

gauge. If the gauge has returned to zero, check for

leakages in the refrigerant piping.

5. Re-open the manifold valves and continue vacuum

drying for at least 2 hours and until a pressure difference

of 0.1 MPa or more has been achieved. Once the

pressure difference of at least 0.1 MPa has been

achieved, continue vacuum drying for 2 hours. Close the

manifold valves and then stop the vacuum pump. After 1

hour, check the pressure gauge. If the pressure in the

piping has not increased, the procedure is finished. If the

pressure has increased, check for leakages.

6. After vacuum drying, keep the manifold connected to

the master unit stop valves, in preparation for refrigerant

charging.

Leak detection

The general methods for identifying the source of a leak

are as follows:

1. Audio detection: relatively large leaks are audible.

2. Touch detection: place your hand at joints to feel for

escaping gas.

3. Soapy water detection: small leaks can be detected by

the formation of bubbles when soapy water is applied to

a joint.

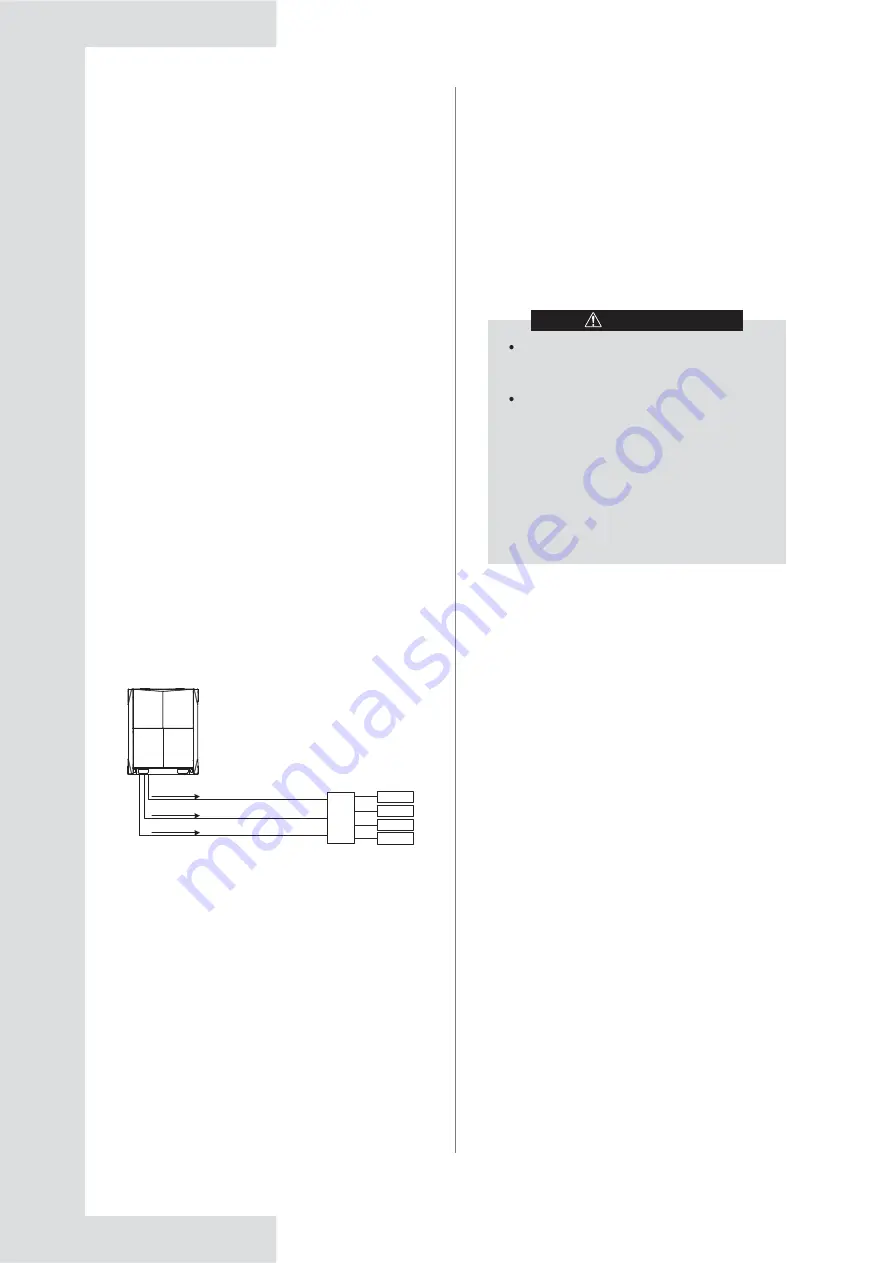

Fig. 5-17

5.7 Vacuum Drying

Before performing vacuum drying, make sure

that all the outdoor unit stop valves are firmly

closed.

Once the vacuum drying is complete and the

vacuum pump is stopped, the low pressure in

the piping could suck vacuum pump lubricant

into the air conditioning system. The same

could happen if the vacuum pump stops

unexpectedly during the vacuum drying

procedure. Mixing of pump lubricant with

compressor oil could cause compressor

malfunction. Therefore a check valve should

be used to prevent vacuum pump lubricant

seeping into the piping system.

CAUTION

MS

Liquid pipe

High pressure gas pipe

Low pressure gas pipe

Nitrogen

Nitrogen

Nitrogen

A

Indoor unit

B

C

D

Outdoor unit

23