14

WARNING: Do not drain carburetor if

using fuel stabilizer. Never use engine or

carburetor cleaning products in the fuel

tank or permanent damage may occur.

NOTE: Fuel stabilizer (such as STA-BIL) is an accept-

able alternative in minimizing the formation of fuel gum

deposits during storage. Add stabilizer to gasoline in fuel

tank or storage container. Always follow mix ratio found

on stabilizer container. Run engine at least 10 minutes

after adding stabilizer to allow it to reach the carburetor.

Do not drain carburetor if using fuel stabilizer.

4. Remove the spark plug and pour one (1) ounce

of engine oil through the spark plug hole into the

cylinder. Cover spark plug hole with a rag and crank

the engine several times to distribute the oil. Replace

spark plug.

NOTE: Refer to the engine manual for more information

on preparing the snow thrower engine for storage.

Preparing Snow Thrower

1. When storing the snow thrower in an unventilated or

metal storage shed, care should be taken to rustproof

the equipment. Using a light oil or silicone, coat the

equipment, especially any chains, springs, bearings

and cables.

2. Remove all dirt from exterior of engine and equipment.

3. Follow lubrication recommendations on page 12.

4. Store equipment in a clean, dry area.

If the snow thrower will not be used for 30 days or

longer, or if it is the end of the snow season when the

last possibility of snow is gone, the equipment needs to

be stored properly. Follow storage instructions below to

ensure top performance from the snow thrower for many

more years.

Preparing Engine

NOTE: Refer to the engine manual for more detailed

information on preparing the snow thrower engine for

storage.

WARNING: Never store snow thrower

with fuel in tank indoors or in poorly

ventilated areas, where fuel fumes

may reach an open flame, spark or

pilot light as on a furnace, water

heater, clothes dryer or gas appliance.

NOTE: It is important to prevent gum deposits from

forming in essential fuel system parts of the engine such

as the carburetor, fuel filter, fuel hose or tank during

storage.

CAUTION

:

Alcohol blended fuels (called gasohol

or using ethanol or methanol) can attract moisture

which leads to separation and formation of acids

during storage. Acidic gas can damage the fuel

system of an engine while in storage.

To avoid engine problems, the fuel system should be

emptied before storage for 30 days or longer. Follow

these instructions to prepare your snow thrower for

storage:

WARNING: Drain fuel into an approved

container outdoors, away from any

open flame. Be certain engine is cool.

Do not smoke. Fuel left in engine

during warm weather deteriorates and

will cause serious starting problems.

1. Remove all gasoline from the carburetor and the fuel

tank to prevent gum deposits from forming on these

parts and harming the engine.

2. Run the engine until the fuel tank is empty and it

stops due to lack of fuel.

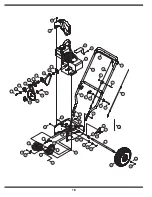

3. Drain carburetor by pressing upward on bowl drain,

located below the carburetor cover. See Figure 14.

7

Off-Season

Storage

Never store snow

thrower with fuel

in tank indoors or

in poorly ventilated

areas, where fuel

fumes may reach an

open flame, spark

or pilot light as on a

furnace, water heater,

clothes dryer or

gas appliance.

Drain fuel into an

approved container

outdoors, away from

any open flame. Be

certain engine is

cool. Do not smoke.

Fuel left in engine

during warm weather

deteriorates and

will cause serious

starting problems.

Do not drain

carburetor if using

fuel stabilizer.

Never use engine or

carburetor cleaning

products in the fuel

tank or permanent

damage may occur.

WARNING

Carburetor

Bowl Drain

Figure 14