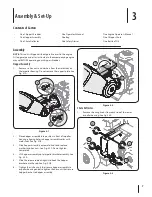

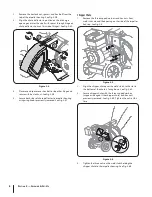

Maintenance & Adjustments

6

13

Maintenance

General Recommendations

Always observe safety rules when performing any

•

maintenance.

The warranty on this chipper shredder does not cover

•

items that have been subjected to operator abuse or

negligence. To receive full value from warranty, operator

must maintain the equipment as instructed here.

Changing of engine-governed speed will void engine

•

warranty.

All adjustments should be checked at least once each

•

season.

Periodically check all fasteners and make sure these are

•

tight.

WARNING:

Always stop engine, disconnect spark

plug, and ground against engine before, cleaning,

lubricating, or performing any type of maintenance

on your machine.

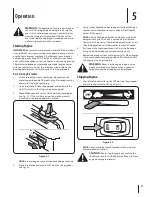

Lubrication

Lubricate the release rod and spring with light oil once a

1.

season. See Fig. 6-1.

Lubricate the pivot points on the hopper with light oil once

2.

a season.

Lubricate the pivot points on the chute deflector with light

3.

oil once a season.

Follow the separate engine manual packed with your unit

4.

for engine lubrication instructions.

Equipment Care

Clean the chipper shredder thoroughly after each use.

•

Wash bag periodically with water. Allow to dry thoroughly

•

in shade.

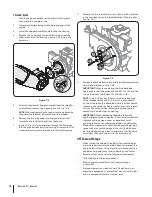

If the discharge area becomes clogged, remove flail screen

•

and clean as instructed below.

NOTE:

Cleaning with a forceful spray of water is not

recommended as it could contaminate the fuel system.

Engine Care

Refer to the Maintenance section of the Engine Owner/ Operator

manual packed with your unit. Read and follow instructions

carefully.

Check engine oil level before each use as instructed in the

•

separate engine manual.

Clean or replace air cleaner every 25 hours under normal

•

conditions. Clean every few hours under extremely dusty

conditions. To service the air cleaner, refer to the engine

manual.

The spark plug should be cleaned and the gap reset once

•

a season. Check engine manual for correct plug type and

gap specifications.

Clean engine regularly with a cloth or brush. Keep the

•

top of the engine clean to permit proper air circulation.

Remove all grass, dirt, and combustible debris from muffler

area.

Figure 6-1

Содержание 24A-45M3000

Страница 19: ...Notes 10 19...