Electrical

Symptom

Possible Cause

Remedy

Nothing Works

(1) Disconnect switched to OFF.

(2) Power Supply to saw OFF.

(3) Line fuse blown.

(4) Safety feature activated

(1) Visual Check

(2) Visual Check

(3) Replace

(4) Check:

E-Stop Buttons

Cable Pull Switch

Bump Bar

Air supply to saw

Saw motors/Waste

system motors

wont run

(1) Starter Overload tripped.

(2) Thermal units loose or worn out.

(3) Loose wires at motor, starter,

and/or switch.

(4) Malfunction in contact blocks on

pushbutton.

(5) Safety feature activated

(1) Reset

(2) Check and replace if

needed.

(3) Check connections and

tighten as needed.

(4) Perform continuity test

on contact block.

(5) Check safety system

components.

Motor runs

erratically or

“jumps”

(1) Badly worn brushes

(2) Insufficient torque by motor.

(1) Replace as needed

(2) Call MDI tech for

parameter adjustment.

Lumber Conveyor

speed won’t adjust

(1) Speed pot defective

(2) Power supply unbalanced

(1) Replace

(2) Call for assistance,

isolation transformer

may be needed.

29

Содержание DESAUW FWA500

Страница 1: ...MONET D ES AUW INCORPORATED 877 642 4900 ...

Страница 2: ......

Страница 3: ......

Страница 4: ......

Страница 12: ...8 Moveable End Electrical Cabinet Operator s Side Catcher s Side ...

Страница 13: ...9 Blade 3 Guard ...

Страница 16: ...12 ...

Страница 17: ...13 ...

Страница 18: ...14 ...

Страница 19: ...15 ...

Страница 31: ...MAINTENANCE SCHEDULE SERVICE SCHEDULE 27 ...

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 42: ......

Страница 43: ...Monet Desauw Inc FWA 500 Maintenance ...

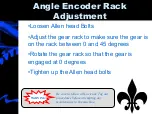

Страница 45: ...Angle Encoder Rack Adjustment ...

Страница 47: ...Angle Encoder Adjustment ...

Страница 48: ...Setting The Angle Digital Readout Scale Factor ...

Страница 49: ...Angle Encoder D R O Adjustment ...

Страница 51: ...Lower Conveyor Chain Adjustment Video ...

Страница 52: ...Upper Hold Down Chain Tension ...

Страница 54: ...Lower Feed Conveyor Timing ...

Страница 56: ...Carriage Chain Adjustment ...

Страница 58: ...Adjust Guide Bearings Video ...

Страница 60: ...Center Line Adjustment Video ...

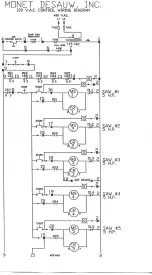

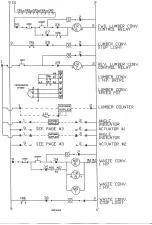

Страница 62: ...Electrical Cabinet Components Variable Speed Frequency Drive ...

Страница 63: ...Electrical Cabinet Components Control Relays ...

Страница 64: ...Electrical Cabinet Components Transformer for 110 ...

Страница 65: ...Electrical Cabinet Components Fuses and Fuse Blocks ...

Страница 66: ...Electrical Cabinet Components Motor Starters ...

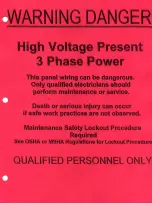

Страница 67: ...Electrical Cabinet Components Lock Out Tag Out Disconnect ...

Страница 69: ......

Страница 70: ......

Страница 71: ......

Страница 72: ......

Страница 73: ......

Страница 74: ......

Страница 75: ......

Страница 76: ......

Страница 77: ......

Страница 78: ......

Страница 79: ......

Страница 80: ......

Страница 81: ......

Страница 82: ......

Страница 83: ......

Страница 84: ......

Страница 85: ......