USER INSTRUCTIONS

MOD 70

WARNING!

Personnel using this system should be suitably trained, competent and have a clear

understanding of Safe Slinging procedures.

The use of Modulift equipment must be in accordance with the procedures laid down in ‘Lifting

Operations and Lifting Equipment Regulations 1998’ (LOLER).

NEVER EXCEED STATED SWL - ADHERE TO SWL IN TABLE 2, FOR PARTICULAR SLING

ANGLE USED

THE TOP SLING LENGTH IS CRITICAL TO THE SAFE USE OF THE SPREADER - ADHERE

TO TABLE 2.

Ensure Drop Links hang down, and smaller shackles are connected to bottom hole of Drop Link.

Do not under any circumstances hang load(s) from the tube or flanges - the spreader is designed

for axial compression - not bending.

MOD 70 - Beam Specification.

Rated at 70 tonnes SWL at 9 metres span (

30° STV)

. See Load Table for SWL at longer spans.

‘Sling to Vertical’ angle,

β

,

45 degrees or less.

End Units & Drop Links are rated at 35 tonnes WLL each (70 tonnes combined capacity).

Bolt tightening torque: 150Nm.

Spanner size required: 30mm.

Recommended additional equipment: Torque Wrench, Podger Spanner and Ring Spanner.

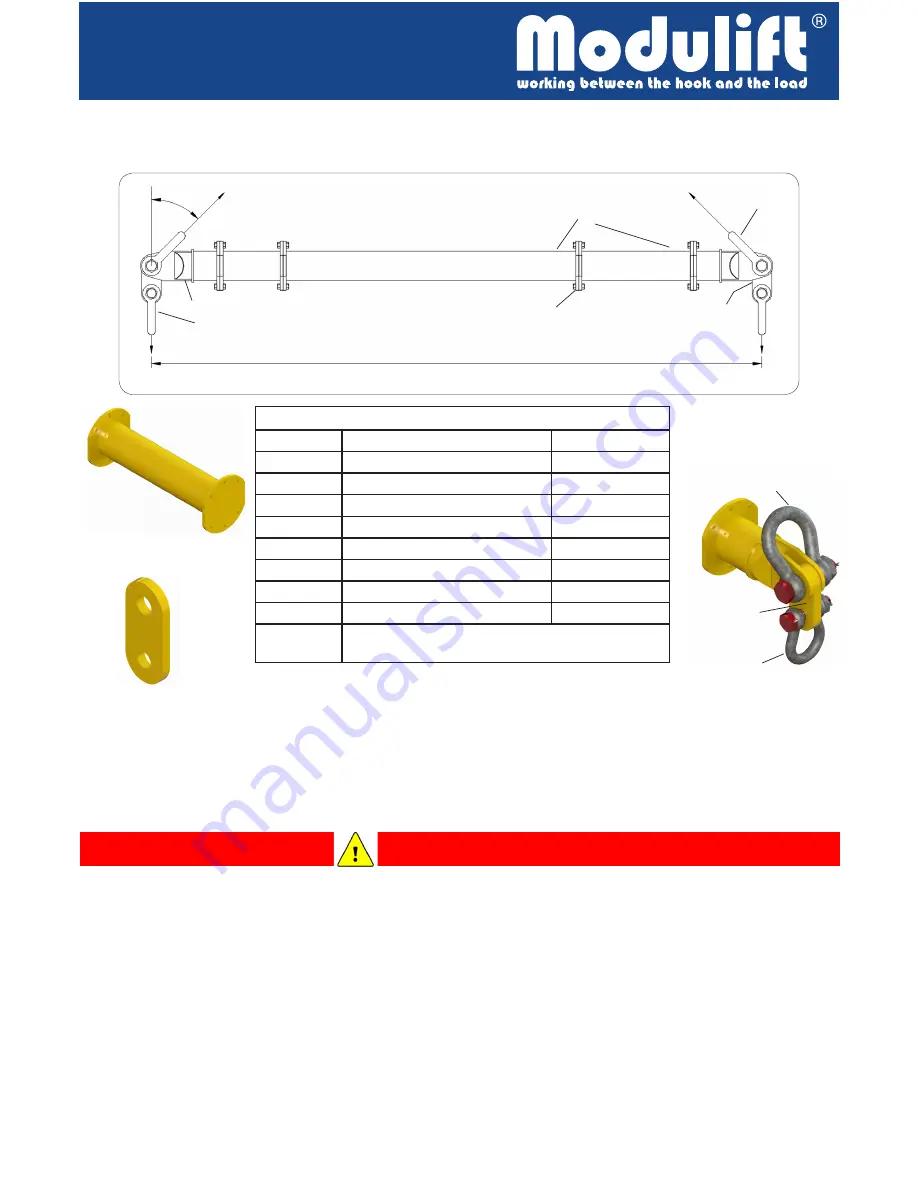

The Modulift Spreader is modular in length. Every spreader consists of 1 pair of End Units & Drop

Links, with intermediate struts that can be bolted into the assembly to achieve different spans. The

MOD 70 has an assembled span ranging from 1 metre to 12 metres in 0.5 metre increments.

TABLE 1: COMPONENT LIST

PART REF: DESCRIPTION

WEIGHT / ITEM

P1

END UNIT

56kg

P2

DROP LINK

17kg

P3

4.0m STRUT

240kg

P4

2.0m STRUT

136kg

P5

1.0m STRUT

85kg

P6

0.5m STRUT

61kg

P7

55t SHACKLE

40kg

P8

35t SHACKLE

20kg

P9

M20x65, GRADE 8.8 HT BOLTS, NUTS &

WASHERS

DROP

LINK

STRUT

END UNIT

SUB-ASSY

Smaller

shackle

Larger

shackle

Drop

Link

Fig.1: Typical Spreader Assembly.

P7

P9

P2

P1

P3 - P6

P8

b

Fig. 1: Typical Spreader Assembly.

β

=’Sling to Vertical’ angle

Span