937A Multi-Sensor System

A.10

Preventing Contamination in a Pirani Sensor

Locate and orient a Pirani sensor to avoid contamination which might affect

the tube's element. For example, if a sensor is installed directly above a

roughing pump in the system, oil vapor could contaminate the tube's filament

wire and cause the calibration to shift.

Install a Pirani sensor with the vacuum port facing downward whenever

possible to prevent particulates and liquids falling or flowing into it. Using a

screen or porous filter at the port is helpful. Try an HPS

TM

Product seal and

centering ring assembly with a screen (see Accessories, p.67).

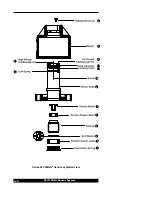

Series 315/345 Pirani Sensor

Orienting the Series 315/345 Pirani Sensor

Operating position has no effect on accuracy. The Pirani sensor was

designed to minimize the effects of convection. In a standard Pirani

system, the ouput of the sensor changes very little between the horizontal

and vertical position.

The Series 315/345 Pirani sensor exhibits slight convection

characteristics near atmosphere. Therefore, the best accuracy can be

achieved above 30 Torr by calibrating the sensor oriented vertically with

the port facing down. The Pirani sensor can be calibrated at any pressure

between 600 and 1000 Torr.

Connecting the Series 315/345 Sensor

To fit a KF 16 port to a KF 10 port, use an HPS adaptive centering ring

(HPS™ PN 100315821)

To install the Sensor with a

1

/8" NPT,

do not use the case for tightening. Use

the

9

/16" hex flats on the sensor’s vacuum tubing for tightening. Wrap about

two turns of Teflon

®

tape on the threads of the Sensor in the direction of the

threading to ensure a leak-free seal.

Do not use a compression mount (quick connect) to attach the

Sensor to a system in positive pressure applications.

Positive pressures might blow the Sensor out of a compression fitting,

damaging equipment and possibly injuring personnel.

A solid electrical connection between the Sensor and the

grounded vacuum system must be provided to shield the tube

element from external radiation sources.

In applications where the system may be exposed to large voltage

fluctuations, a centering ring with a screen should be installed, and the

screen and tubing then grounded. The clamp must be tightened properly so

the flange contacts the centering ring.

Содержание HPS 937A Series

Страница 1: ...HPSTM Series 937A High Vacuum Multi Sensor System OPERATION AND MAINTENANCE MANUAL...

Страница 2: ......

Страница 3: ...August 1998 Part 100009273 Rev 4 0 HPSTM Series 937 A High Vacuum Multi Sensor System...

Страница 79: ...71 937A Multi Sensor System Notes...

Страница 83: ...937A Multi Sensor System A 4 Series 423 I MAG Sensor exploded view 13 15 14 12 11 10 9 8 7 6 5 4 3 1 2...

Страница 107: ......

Страница 108: ......