– 7 –

7

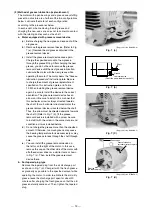

. WIRING

(1) Wiring procedures

Wiring work must be done according to the Electrical Equipment Technical Standards and Interior Wiring

Code by a trained worker using suitable wiring tools. Working with live wires is dangerous. Always turn the

power OFF before starting the work. The outline of the wiring requirements is shown in Table 5. If the wiring

distance is long, the voltage drop will increase.

In this case, wire so that the voltage drop is 2% or less during

motor operation.

Table 5 Motor wiring

Output

(kW)

Min. wire thickness

*1

Max. distance of

electrical wiring

*2

Overcurrent circuit breaker (A)

*3

Rated current of

excess graduation

current meter for

motor (A)

Min. grounding wire

thickness

Full-voltage

starting

Using starter

(Star-delta starter)

200V

class

400V

class

200V

class

400V

class

200V

class

400V

class

200V

class

400V

class

200V

class

400V

class

200V

class

400V

class

0.75 1.6 mm 1.6 mm 54 m

217 m

15

15

-

-

5

5

1.6 mm 1.6 mm

1.5

1.6 mm 1.6 mm 32 mm 130 m

30

15

-

-

10

5

1.6 mm 1.6 mm

2.2

1.6 mm 1.6 mm 23 mm 94 m

30

15

-

-

10

5

1.6 mm 1.6 mm

3.7

2.0 mm 1.6 mm 23 mm 60 m

50

30

-

-

15

10

2.0 mm 1.6 mm

5.5

5.5 mm

2

1.6 mm 27 mm 40 m

75

40

40

20

30

15

5.5 mm

2

2.0 mm

7.5

8 mm

2

2.0 mm 31 mm 48 m

100

50

50

30

30

15

5.5 mm

2

2.0 mm

11

14 mm

2

5.5 mm

2

37 mm 57 m

125

75

75

40

60

30

8 mm

2

5.5 mm

2

15

22 mm

2

8 mm

2

43 mm 65 m

125

100

100

50

60

30

8 mm

2

5.5 mm

2

18.5 38 mm

2

14 mm

2

61 mm 93 m

125

100

125

60

100

40

8 mm

2

5.5 mm

2

22

38 mm

2

22 mm

2

51 mm 124 m

150

125

125

75

100

60

8 mm

2

8 mm

2

30

60 mm

2

22 mm

2

62 mm 92 m

200

125

175

100

150

60

14 mm

2

8 mm

2

37

100 mm

2

38 mm

2

86 mm 126 m

250

125

225

125

200

100

22 mm

2

8 mm

2

(*1) The minimum wiring thickness is for when three wires are placed in a conduit (full-voltage starting).

(*2) The guideline for the maximum distance of an electrical wiring is that the voltage drop at the distant end is to be 2% or less for the minimum wire

thickness.

(*3) The overcurrent circuit breaker is for power distribution. To protect a motor with a circuit breaker, choose a circuit breaker commensurate with the

rated output of that particular motor.

There are three classes of general motor insulation, Class E, Class B and Class F. If high-temperature insulation

material such as Class F insulation is used, the temperature in the terminal box will be relatively high. Thus, use

wiring cables and insulation tape that have a high temperature resistance. (Refer to Table 6.)

Table 6 Examples of motor wiring materials

Thermal

class of

motor

Wiring material (Example)

Insulation wiring

Cable

Insulation tape

Tolerable

max.

temp.

°C

Tolerable

max.

temp.

°C

Tolerable

max.

temp.

°C

120(E)

130(B)

Vinyl insulated wire

Rubber insulated wire

Class 2 vinyl insulated wire

Polyethylene insulated wire

Ethylene propylene rubber insulated wire

Bridged polyethylene insulated wire

60

60

75

75

80

90

Vinyl cable

Natural rubber cable

Polyethylene cable

Butyl rubber cable

EP rubber cable

Bridged polyethylene cable

60

60

75

80

80

90

Vinyl adhesive tape

Self-fusing butyl rubber tape

Polyester adhesive tape

60

80

120

155(F) Bridged polyethylene insulated wire

Silicon rubber insulated glass mesh wire

90

180

Bridged polyethylene cable

Silicon rubber cable

90

180

Polyester adhesive tape

Silicon glass adhesive tape

120

180

Remarks : The tolerable max. temperature indicates the main examples for each material. Some products may tolerate a higher temperature. Consult

the manufacturer for details.

(2) Grounding (earthing)

The insulation material of the motor is an insulator and also is a conductor. Thus, the motor has a capacitance

between the ground. If the motor is not grounded, an induction voltage that is approx. 50 to 60% of the power

voltage may be generated in proportion to this capacitance between the frame and ground. To prevent accidents

caused by electric shocks,

always ground the motor according to the Electrical Equipment Technical

Standards Clause 18 to 28. A grounding screw is provided in the motor's terminal box or on the lower part of the

frame. If the grounding screw loosens due to vibration during operation, sparks may be ignited at the grounding

section. Wire the grounding wire so that the grounding screw will not loosen because of the grounding wire

vibrating, and lock the grounding screw.