18

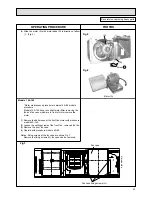

OPERATING PROCEDURE

PHOTOS

Be careful on removing heavy parts.

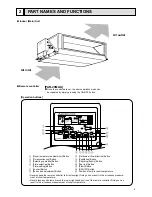

Fig.4

Fig.5

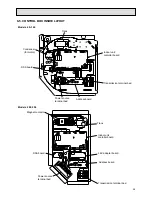

Models 200

·

250

1.Removing the control box cover

(1) Remove the fixing screws (four) of the control box cover (C),

and remove the cover. (Fig. 4)

*At this stage, the following servicing is possible.(Fig. 5)

1 Operation and check of the switches (listed below) which

are on the control board.

• Dip switch SW2 · · · · · · · · · · ·Capacity code setting

• Dip switch SW3 · · · · · · · · · · ·Function change

• Dip switch SW4 · · · · · · · · · · ·Model code setting

2 Connection check of the lead wires (listed below) which are

connected to the controller board.

• Power supply lead wire.

• Network remote contoller transmission lead wire.

• Fan motor lead wire.

• LEV lead wire

• Intake air sensor lead wire

• Liquid piping sensor lead wire

• Gas piping sensor lead wire

• Power supply transformer lead wire

• Address board lead wire

(• Drain pump lead wire)

(• Drain sensor lead wire)

3 Control board exchange

4 Power supply transformer exchange

5 Arrest exchange

6 Intake air sensor exchange

7 Operation and check of the switches (listed below) which

are on the address board

• Rotary switches SW11, 12 · · · ·Address setting

• Rotary switch SW14 · · · · · · · · · ·Branch port setting

• Dip switch SW1· · · · · · · · · · · · · ·Function change (main)

8 Address board exchange

9 Power supply terminal bed exchange

10 Transmission terminal bed exchange

( ):Optional parts

(C)