28MT Multi-Tool

3

Original Instructions Version December 15

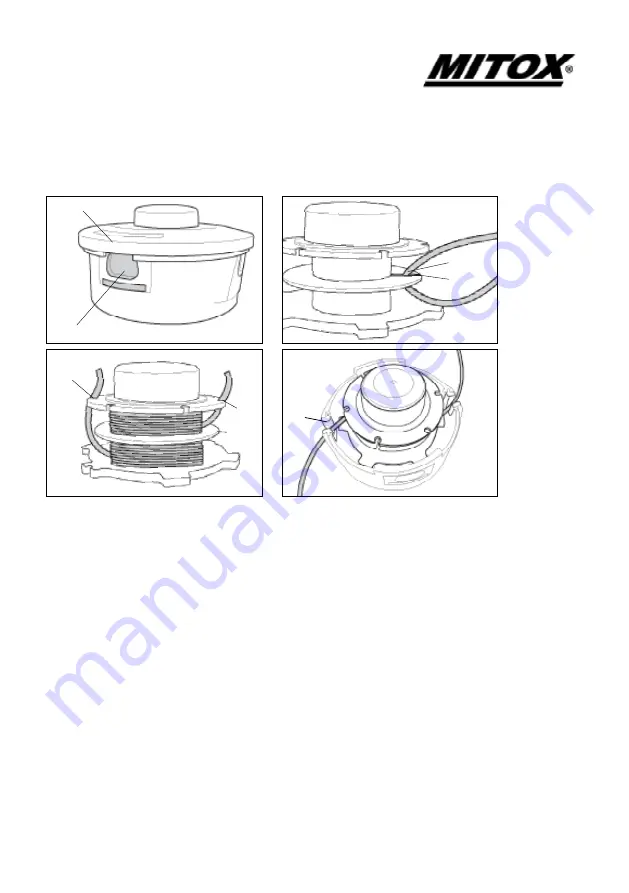

Replacing the Nylon Cord

Check to see if the nylon head is damaged before replacing the cord. If you can see serious traces

of wear or damage, you must replace the complete nylon head.

1. Stop the engine.

2. Open the nylon head by pushing on the catch, (a), and lifting the cover (b).

3. Pull the bobbin out of the nylon head and take out the rest of the nylon cords.

4. Cut a new length of cord, 2.4mm Ø and 5 metres long.

5. Fold the new cord in half and place the centre of the fold (c) into the clip (d) in the empty bobbin.

6. Wind the line in the direction of the arrows on the bobbin, with half of the line above and half

below the divider (e). Maintain an even and firm tension onto the bobbin, being careful not to twist

the line.

6. After winding the cord, insert both ends into the notches on the bobbin, (f).

7. Put the filled bobbin back into the carrier. Release the cords from the notches in the bobbin

and place them into the eyelets in the carrier (g). The cords should stick out appx 15 cm either

side.

8. Refit the spool cover (b), ensuring it is securely clicked into place.

Never use a cutting device other than those supplied by the manufacturer. (Steel cord is never

allowed) Always use original spare parts in order to benefit from continuous warranty.

(a)

(b)

(g)

(f)

(e)

(f)

(c)

(d)