14

mvip@mitech-ndt.com

impact direction of that impact device.

The calibration results are stored in the EEPROM of the main unit and the stored calibration

results will not be lost until next calibration or system reset.

4.4 Multi-point calibration

This instrument provides conversion curves into standard hardness scales for a series of materials. For

special solutions it is possible for the user to correct conversion functions if conversions display

systematic deviations.

Multi-point calibration uses a standard conversion function

std

H

(L) and adds a straight line, which is

determined by at least two reference test points using least squares approximation method, so that the

resulting conversion function H(L) coincides all the reference points.

Multi-point calibration is typically used if at least two workpieces with known and significantly distinct

hardness values in the required scale are available. The workpieces to be measured are made from the

same material and are neither significantly harder than the hardest reference piece nor significantly

softer than the reference piece.

Before starting the multi-point calibration process, prepare 2 to 5 reference blocks with known hardness

value calibrated using other test method. The reference blocks should conform to the measuring

conditions of this instrument. Procedure of the multi-point calibration

:

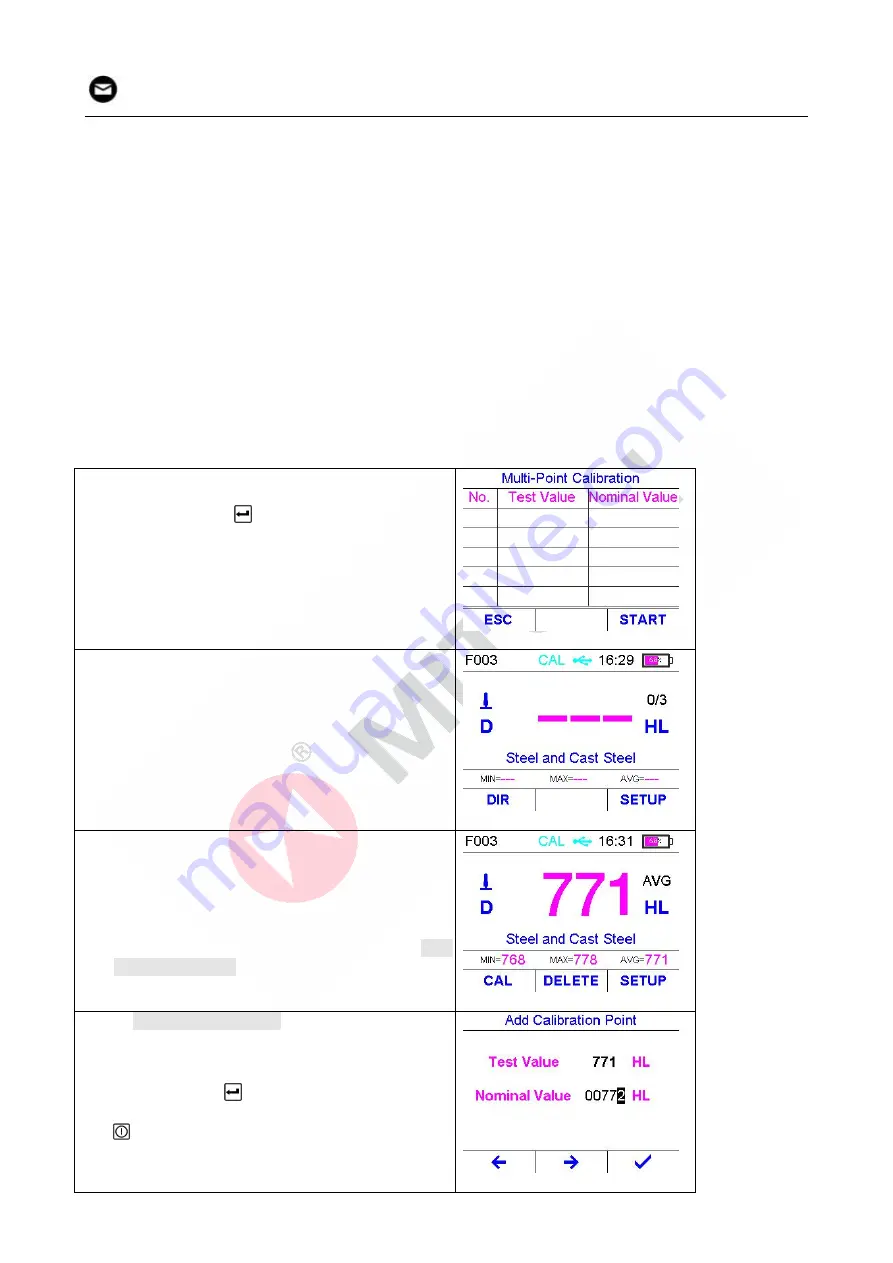

Step 1, open multi-point calibration dialog box.

Step 2, Press

or F3 key to start the

calibration process.

The display will be switched back to the main screen

automatically when the multi-point calibration

process starts.

On the main screen, please note that “CAL”

characters appear on top of the screen indicating

calibration in process.

Step 3, Configure the impact device, material

selection and hardness scale settings.

Step 4, Test the hardness value of the first

reference block.

When the test series closes, “CAL” command will

appear on bottom-left of the main screen. Then

continue:

Step 5, Press F1 key to add a new calibration

point to the calibration points series. The Add

Calibration Point dialog box will be opened

automatically.

On the Add Calibration Point dialog box, the average

test value is displayed.

Step 6, Input the nominal value of this reference

block by pressing F1, F2 and arrow keys.

Step 7, Press

or F3 key to complete the

addition of the new calibration point. Or press

key to discard this new calibration point and

close the dialog box.