6

MAINTENANCE OF MACHINE

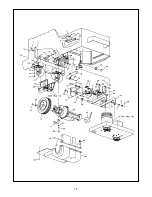

VACUUM MOTOR

Motor brushes can be replaced with Brush Set, Part No. 741008. Brushes should be replaced only

once. More than once brush replacement will cause very high current consumption. This undue current

consumption lowers overall machine performance and is not in the best interest of economical machine

use.

CARBON BRUSHES IN DRIVE MOTOR

Inspect these brushes once every 18 months or 720 hours.

The brushes can now be inspected by removing the brush caps near the end of the drive motor.

Examine all four brush lengths; if the back end of a brush is even with the edge of the brush holder or

shorter, the brush must be replaced. Replace with Brush Set, Part No. 744155. When installing new

brushes, also inspect cummutator for pits and/or excessive wear. If it is in poor condition, replace

drive motor with Part No. 744154.

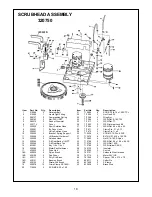

CARBON BRUSHES IN BRUSH DRIVE MOTORS

Inspect these brushes once every six months or 360 hours.

Remove scrub head assembly. Examine brush lengths; if the back end of brush is even with the edge

of the brush holder or shorter, the brush must be replaced. Replace with Part No. 833474. When

installing new brushes, also inspect commutator for pits and/or excessive wear. Replace motor with

Part No. 833379 if commutator is in poor condition.

LUBRICATION

1. Grease casters once every week (two fittings per caster) or 15 hours.

2. Oil all moving parts such as hinges and pressure points once every month or every 60 hours.

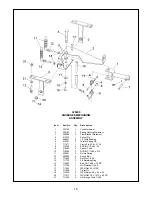

SQUEEGEE RUBBERS

When the thick rear squeegee rubber is damaged or worn excessively, it will cause streaking and

poor solution pickup. Extended rubber life and be obtained by reversing it, provided it is not torn or

otherwise damaged.

TANKS

At the end of a day’s work (or work cycle, both the vacuum and solution tanks should be drained and

flushed with warm water.

Once a week or 15 hours the vacuum tank should be cleaned of settled debris. This can be done by

lowering the drain hose and washing out the debris.

BATTERIES (956720, 956740)

Periodically remove batteries from machine. Clean batteries, battery tray, and battery compartment

with a solution of baking soda and water. Check all battery cables and wiring for signs of damage or

wear. Replace as needed. Check battery fluid level each charge. Check electrolyte with hydrometer

every 15 hours.

Содержание Powerboss PB32036CE

Страница 2: ......

Страница 11: ...8 ...

Страница 15: ...12 ...

Страница 17: ...14 ...

Страница 19: ...16 ...

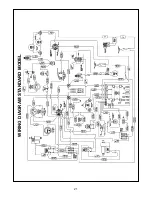

Страница 24: ...21 WIRING DIAGRAM STANDARD MODEL ...

Страница 25: ...22 WIRING DIAGRAM CE MODEL ...