7

When this printer has not been used for an extended period of time, or depending on the environmental tempera-

ture, the discharge at the nozzles could become unstable. In such a case, the following methods may be taken to

recover the status of the nozzles.

When the printer is not to be used for a period of one week or above, perform the cleaning of the heads and nozzles

and the ink discharging channel before storing this printer.

Wiper kit 33S (Product No. SPA-0134)

When the solvent ink is used: Cleaning liquid for maintenance MS2/ES3/HS kit (Product No.: SPC-0369)

When aqueous ink is used: Cleaning liquid bottle kit A29 (Product No.: SPC-0137)

Waste ink tank 2 liters (Product No.: SPA-0117)

Cutter blades (Product No.: SPA-0107)

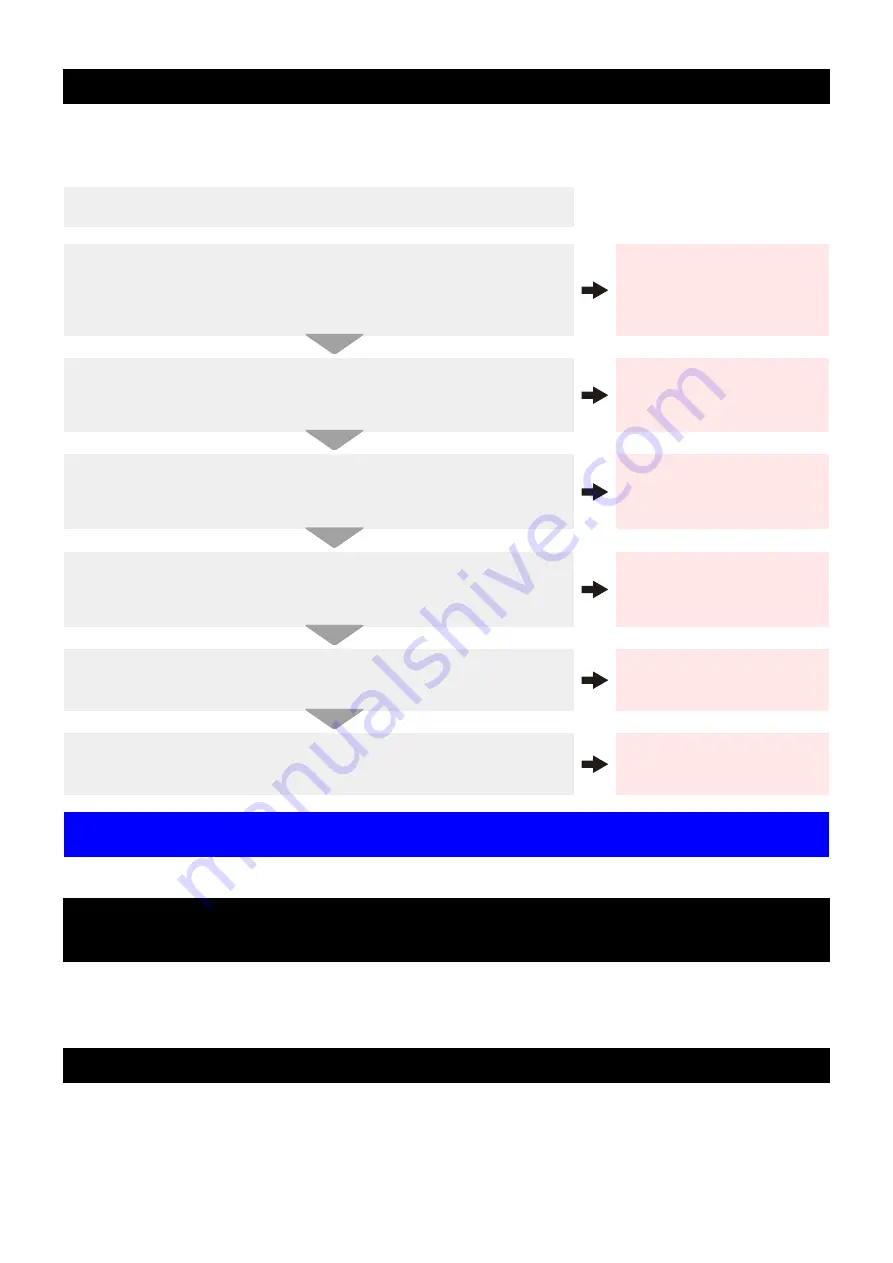

6. Recovery method of defective nozzle discharge

1. Daily maintenance and care

Perform the cleaning of the parts described in this document.

2. Perform head cleaning (normal). Refer to P2-19 of Operation Man-

ual.

After having performed the care and maintenance stated in step 1, perform the

cleaning of the heads in accordance with the procedures stated in Operation

Manual.

Perform test drawing and

check

(P2-18 of Operation Manual)

In the event nozzle missing etc. have not been improved

3. Perform head cleaning (hard). Refer to P2-19 of Operation Manual.

If the nozzle missing does not disappear even after repeating the head cleaning

(normal) several times, reset the cleaning mode to "hard" and perform the

cleaning again.

Perform test drawing and

check

(P2-18 of Operation Manual)

In the event nozzle missing etc. have not been improved

4. Perform the cleaning of the head nozzles. Refer to P4-10 of Opera-

tion Manual.

Perform the cleaning of the head nozzles. In this case, leaving time of the

cleaning liquid for maintenance shall be made [1 minute].

Perform test drawing and

check

(P2-18 of Operation Manual)

In the event nozzle missing etc. have not been improved

5. Perform the cleaning of the head nozzles again. Refer to P4-10 of

Operation Manual

Reset the leaving time of the cleaning liquid for maintenance to [10 minutes],

and perform the cleaning of the head nozzles again.

Perform test drawing and

check

(P2-18 of Operation Manual)

In the event nozzle missing etc. have not been improved

6. Perform cleaning of the ink discharging route.. Refer to P4-12 of

Operation Manual

ÉCPerform the cleaning of the ink discharging route 3 to 5 times.

Perform test drawing and

check

(P2-18 of Operation Manual)

In the event nozzle missing etc. have not been improved

7. Perform the ink filling.. Refer to P4-21 of Operation Manual

Perform the ink filling once or twice.

Perform test drawing and

check

(P2-18 of Operation Manual)

If the nozzle missing has not been improved even with the above operations, please call us

or your sales agent from whom you purchased this printer.

7. When the printer is not used for a long period (P.4-16, Opera-

tion Manual)

8. Supplies