Manual

LOGO 600

- ©Mikado Model Helicopters GmbH - Page 9

2x

4x8x1

2x

M4x14

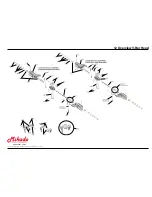

7 Mounting the Motor

8 Mounting the Canopy

Bag 1

Bag 1

Installation of the Motor Pinion

Screw the motor pinion onto the motor shaft, making sure that

it can still be moved. Now mount the motor on the motor plate

and move the pinion so it is aligned well with the main gear.

As visual help for aligning the pinion you may use the small

ridge which separates the two parts of the pinion. When the

pinion is aligned correctly it will easily engage with the main

gear. If the pinion does not engage with the main gear, it is not

correctly aligned. After the pinion is correctly aligned, take the

motor out of the mainframe and tighten the set screw.

Gear Backlash

Move the motor with the pinion until it is limited by the gear.

Tighten one of the M4x14 screws slightly. You must still be able

to swivel the motor around its own axis. In this way you can

easily determine the correct distance between the main gear

and the pinion. There should be no (!) gear backlash. At the

same time, the motor should not (!) exert any pressure onto the

running surface of the main gear. After you have determined

the correct distance, tighten the second M4x14 screw.

Bag 1

available pinions for

module 1 diameter 6 mm

(not included in kit)

10 teeth*

#4410

11 teeth

#4411

12 teeth

#4412

13 teeth

#4413

14 teeth

#4414

15 teeth

#4415

*diameter 5 mm

For very hard 3d flying counterbearing

no. #4373 (30 mm, 6 mm shaft)

should be installed.

Bag 1