7

Symptom: Air leak near top of nailer/stapler or trigger area.

Problem

Loose screws.

Worn or damaged o-rings or seals

Solutions

Tighten screws.

Contact factory for service. +(886) 4 23358567

Symptom: Nailer/stapler does nothing or operates sluggishly.

Problem

Inadequate air supply.

Inadequate lubrication.

tions.

Worn or damaged o-rings or seals.

Solutions

Check compressor settings Check air hose/filters for kinks or

blockage. Oil nailer/stapler per instruc.

Contact factory for service. +(886) 4 23358567

Symptom: Air leak near bottom of nailer/stapler.

Problem

Loose screws.

Worn or damaged o-rings or bumper.

Solutions

Tighten screws.

Contact factory for service. +(886) 4 23358567

Symptom: Nailer/stapler jams frequently.

Problem

Incorrect fasteners.

Damaged fasteners.

Magazine or nose screw loose.

Magazine is dirty.

Driver is worn or damaged.

Solutions

Verify fasteners are the correct size.

Replace with undamaged fasteners Tighten screws.

Clean magazine

Contact factory for service. +(886) 4 23358567

Symptom: Other

Problem

Other

Solutions

Contact factory for service. +(886) 4 23358567

进行安装、操作、维修或更换零件之前,请务必详读本使用手册

工作环境:

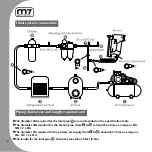

风源及安装需求

1.严格禁止在任何具有爆炸性气体的环境中使用本气动工具。

2.当使用本气动工具时务必站立在坚实稳固的物体或位置上。

3.使用本气动工具的场所, 其通风条件必须十分良好。

4.滑倒、绊倒和从高处跌落…等等状况乃操作气动工具时最容易发生的意外

状况, 因此在操作之前,务必先将工作场所清理干净。

1.操作本气动工具的最大空气压力值不得超过90psi。高于此压力值时将可能对本气动工具

或使用者带来危险险。

2.用于本气动工具的压缩空气必须经过冷却处理, 在空压机出口端务必加装ㄧ只过滤器,以

便过滤压缩空气中的水分。即便如此, 仍会有少部分的水气凝结于空压管路当中, 甚至渗

进本气动工具的机械结构内部, 造成本气动工具难以预期的损害。是故,压缩空气的管路在

进入本气动工具之前的某适当位上, 应予加装ㄧ只三点组合。

3.使用者应根据各种不同气动工具的需求, 选择不同规格的空气压缩机。

4.开始操作本气动工具之前, 应先将管路中的水气排除干净净。如此, 当可避免残留在压缩

空气中的水分或灰尘进入本气动工具内部,将影响到本气工具的正常性能, 甚至造成损坏。

Содержание SJ-1650T

Страница 7: ...7 1 2 3 4 1 90psi 2 3 4...

Страница 8: ...8 1 2 3 4 5 6 7 8 9 1 1 1 1 1 1 1 1...

Страница 9: ...9 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17...

Страница 10: ...10...

Страница 32: ...32...

Страница 33: ...33...

Страница 34: ...34...

Страница 35: ...35...

Страница 36: ......