INSTALLATION AND OPERATION MANUAL, GAS KETTLES, MODELS GL-40FE, GL-60FE

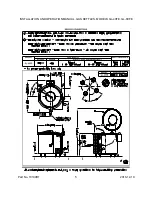

2.0 INSTALLATION

(Continued)

TO INSTALL

1. Uncrate carefully. Report any hidden freight damage to the freight company immediately.

2. Set the unit in place. Be certain to maintain minimum clearances as stated above.

3. To level the unit use a spirit level in all directions on the top of the kettle (lid up).

1. Units with legs - adjust the bottom foot on each leg to overcome an uneven floor.

2. Units with casters - loosen the locking nuts, turn casters in or out as required and

tighten locking nuts.

4. Be certain to leave adequate clearances for cleaning, maintenance and service.

5. The pressure relief valve is located at the left rear of the unit. This area should be kept

clear and should not be in an area where operators will normally stand. The elbow on the

relief valve should be turned toward the floor. A maximum 3 foot, 3/4" diameter pipe may

be used to extend to the floor, but must not be piped directly to a drain. It must vent to the

atmosphere.

6. Check the pressure gauge on the front panel before operating. If the pressure gauge does

not indicate green vacuum zone (below 0 psi), see “Re-establishing Vacuum” section under

SERVICE, after completing installation instructions.

GAS CONNECTION

The serial plate on the lower right side of the unit indicates the type of gas your unit is equipped

to burn. Do

NOT

connect to any other gas type.

A 1" NPT line is provided at the rear for the connection. Each unit is equipped with an internal

pressure regulator which is set for 4" W.C. manifold pressure for natural gas and 10" W.C.

for

propane gas. Use 1/8" pipe tap on the burner manifold for checking pressure.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume

of gas required for satisfactory performance. A steady pressure, minimum 6" W.C. for natural

gas and minimum 11" W.C. for propane gas, is recommended. With all units operating

simultaneously, the manifold pressure on all units should not show any appreciable drop.

Fluctuations of more than 25% on natural gas, and 10% on propane gas, will create pilot

problems and affect burner operating characteristics. Contact your gas company for correct

supply line sizes.

Part No. 10199R1

7

2016-12-19