Step 12 — Run the Job

When all job parameters are set, click on the

Run

step at the top of the interface. The software will download the

vision job just created to the camera and will begin the inspection. Inspection results and the list of active tools

are shown at the right of the image view. That information can also be moved below the image area by

clicking the orientation buttons above the inspection results area.

Test Jobs

Note:

For descriptions of more advanced functionality, such as setting

Inspection Outputs

or using the

Locate Tool

and

Decode Tool

’s

Dynamic Locate

functionality to track multiple tools from image to image,

see the help documentation in AutoVISION software

.

Decode Tool, OCR Tool, Match Strings Tool,

String Format Tool

Measure Tool,

Count Tool

LOT 123456

DATE 05/2024

VISION

SIMPLIFIED

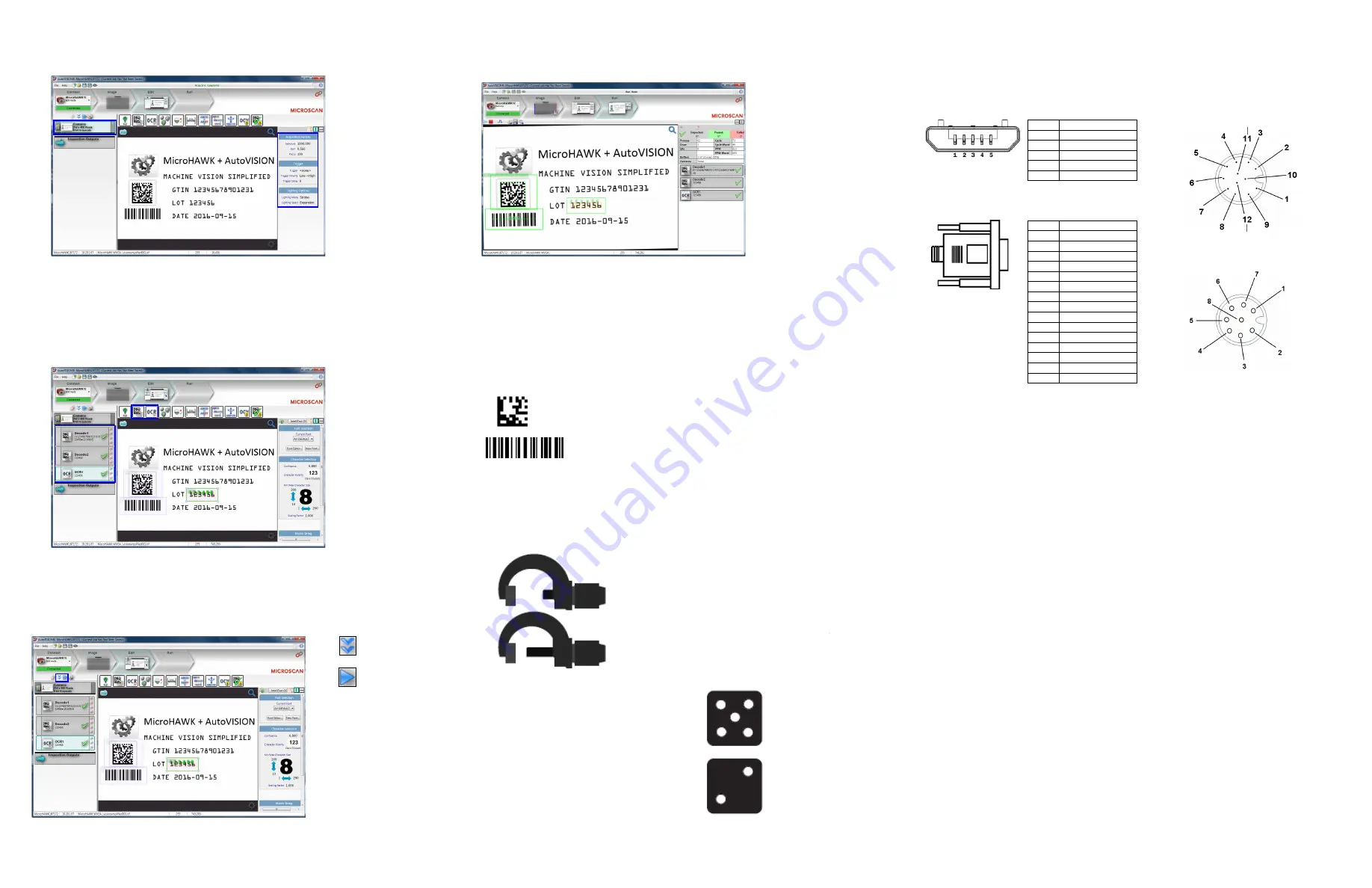

Measure:

Measure the distance between

the jaws of the caliper gauges at left.

Count:

Count the circles on the dice shown

at right.

Step 9 — Set Camera Parameters

1. Click on the

Camera

box to the left of the image area.

2. In the camera parameters below the image area, select the desired type of

Trigger

,

Trigger Polarity

,

Photometry

(Exposure and Gain),

Focus

, and

Lighting

.

Step 10 — Add Tools to the Job

1. Click on the

Decode Tool

or drag it onto the image area.

2. Use the anchor points at the corners of the region of interest to form a box around the Data Matrix

symbol. Leave plenty of space on each side of the symbol.

3. Now add a second Decode Tool and do the same for the 1D symbol below the Data Matrix symbol.

4. Finally, add an

OCR Tool

and drag the region of interest around the area of the image where “123456”

is printed.

Step 11 — Try Out the Job

Once you have configured the tools as desired, use the arrow icons in the Job area to try the job you have

just created.

Note:

Most jobs will inspect multiple captured images. If only one image is being inspected, the effect of the

arrow icons will not be evident.

Try Out Job

Once

Try Out Job

in Loop

Copyright ©2017 Microscan Systems, Inc.

Power Requirements and Pin Assignments

MicroHAWK MV-20:

5VDC ± 5%; 350mA at 5VDC (typ.)

MicroHAWK MV-30:

5V ± 5%; 600mA at 5VDC (typ.)

MicroHAWK MV-40:

4.75V – 30V; 150mA at 24VDC (typ.)

Important:

See the MicroHAWK MV-20 / MV-30 / MV-40 Configuration Guide

for information about

Microscan’s

Isolation Mounting Kit (P/N 98-9000064-01)

to eliminate ground loops or other external

electrical noise through your MicroHAWK MV-30 or MV-40 camera.

MicroHAWK MV-20 Micro-USB Type B Socket

Pin

Function

1

Vbus (5V)

2

D–

3

D+

4

N/C

5

Ground

MicroHAWK MV-30 High-Density 15-Pin Dsub

USB/Serial Socket

MicroHAWK MV-40 M12 Connectors

Pin

Function

1

+5VDC

2

TX232

3

RX232

4

GND

5

D+

6

N/C

7

Output 1+

8

9

10

D–

11

Output 3+

12

Input+ (New )

13

Chassis

14

Output 2+

15

Vbus

Ground

Output 3

Output 1

Output 2

New Master

Default

Power

Input Common

Output Common

RS-232 (Host) RxD

Trigger

RS-232

(Host) TxD

M12 12-pin Plug

Note:

An accessory

cable is required

between the MV-30’s

15-pin corner-exit

cable and the host’s

USB port.

TX (+)

RX (–)

RX (+)

TX (–)

V+

V–

M12 8-Pin Socket (Ethernet)

V+

V–

MicroHAWK MV Part Numbers

MicroHAWK MV part numbers follow the format

7ABX-YZZZ-LPPP

.

7 = MicroHAWK

.

Example Part Number: 7412-2000-2104

Description:

MicroHAWK MV-40, IP65 Case, 24V, Ethernet, Machine Vision, SXGA, 1.2 Megapixel, Mono, High Density,

Autofocus, White Outer LEDs, Auto Verifi Visionscape.

(A) Model

1:

Engine, No Case, USB

2:

MV-20, IP40 Case, USB

3:

MV-30, IP54 Case, 5V, USB

4:

MV-40, IP65 Case, 24V, Ethernet

(B) Application Type

1:

Auto ID and Machine Vision

(X) Sensor

1:

WVGA 0.3 Megapixel, Mono

2:

SXGA, 1.2 Megapixel, Mono

3:

QSXGA, 5 Megapixel, Color

(Y) Optics

0:

Custom

1:

Standard Density

2:

High Density

(ZZZ) Focus Distance

000:

Autofocus

050:

50 mm = 1.96 in.

102:

102 mm = 4.02 in.

190:

190 mm = 7.48 in.

300:

300 mm = 11.81 in.

(L) Illumination

0:

Inner LEDs Only

1:

Red Outer LEDs

2:

White Outer LEDs

(PPP) Software License Bundles

100:

AutoVISION Sensor

101:

AutoVISION

102:

Auto Visionscape

103:

Auto Verification

104:

Auto Verifi Visionscape

Notes:

•

(A) Model:

The MicroHAWK Engine is available for OEM-certified partners only.

•

(L) Illumination:

Outer LEDs provide extra illumination. Base level illumination included with all cameras.

•

Field Upgrades:

Not available for optics or illumination due to factory settings for optical alignment, LED balancing, and

sealing for IP enclosure rating. However, the camera’s software is field-upgradeable via licenses.